Moving/fixed cutter needle plate of lockstitch sewing machine

A fixed knife and needle plate technology, which is applied to sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problems of reducing the service life of the machine, increasing the production cost, and accelerating the wear of the machine, so as to reduce the production cost, easy to install, The effect of increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

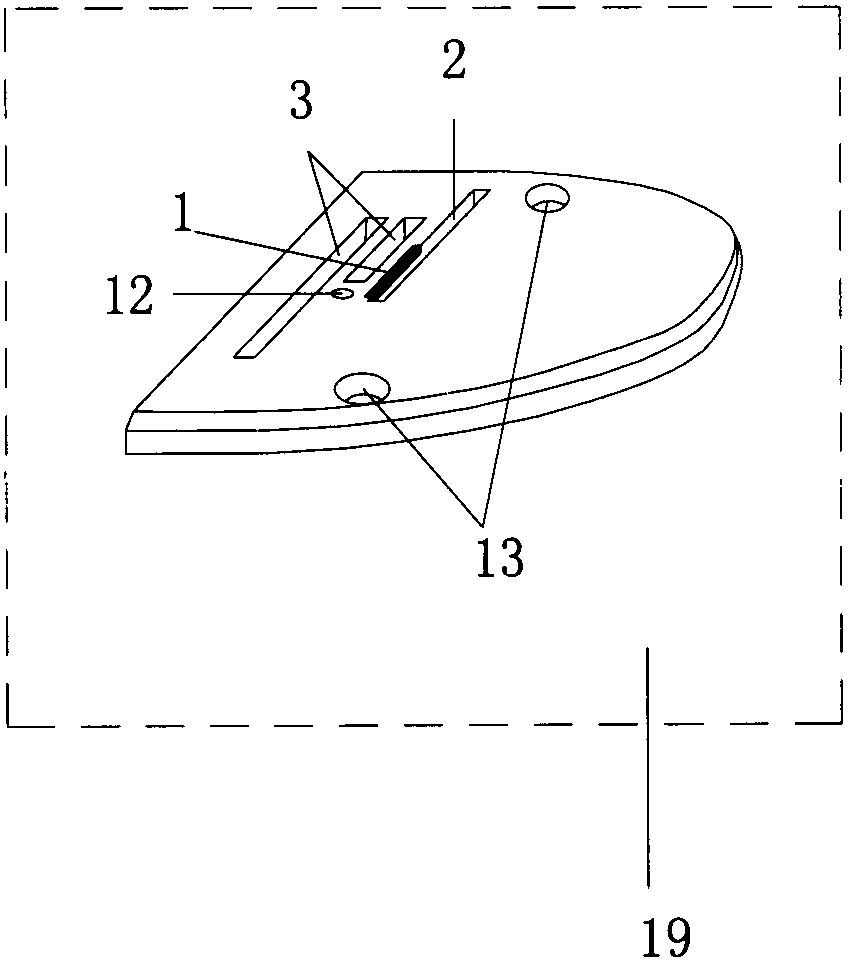

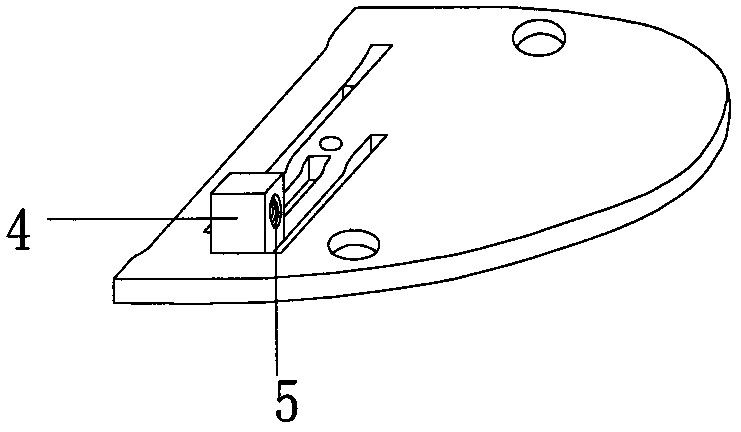

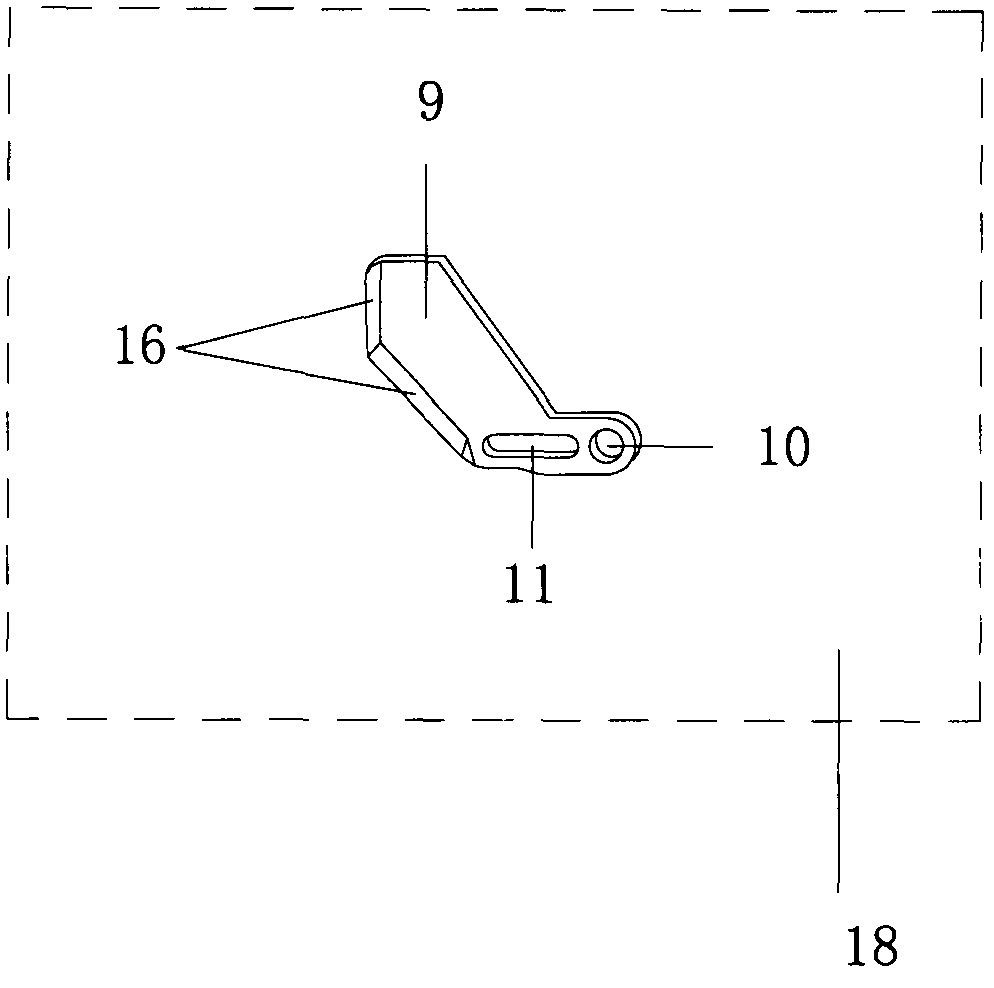

[0012] Moving fixed knife needle plate 19 is rented by fixed knife 1, moving knife groove 2, tooth groove 3, moving knife fixed block 4, moving knife fixed block screw hole 5, pinhole 12, needle plate fixed hole 13. Moving knife 18 is made up of moving knife blade body 9, moving knife fixed turning hole 10, feeding tooth transmission shaft sliding groove 11, moving knife blade 16. Feeding tooth 17 is made up of feeding tooth rack 7, feeding tooth transmission shaft 8, feeding tooth fixing hole 14, tooth 15.

[0013] Take out the movable and fixed knife needle plate 19, put the movable knife 18 into the movable knife groove 2, use the movable knife fixing screw 6 to pass through the fixed rotating hole 10 of the movable knife, and fix the movable knife fixing block screw on the moving knife fixing block 4 In the hole 5, drop the moving knife 18 below the needle plate 19 of the moving and fixed knife, take out the feeding tooth 17, let the feeding tooth transmission shaft 8, put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com