Ventilation cap

A ventilation cap and end cap technology, applied in the field of ventilation caps, can solve the problems of inconvenient operation of equipment, increase the overall cost of production and use, etc., and achieve the effect of simple and easy replacement process and improved adaptability to working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The core of the present invention is to provide a vent cap, which can easily and quickly replace the filter element and adapt to the needs of different working conditions.

[0014] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

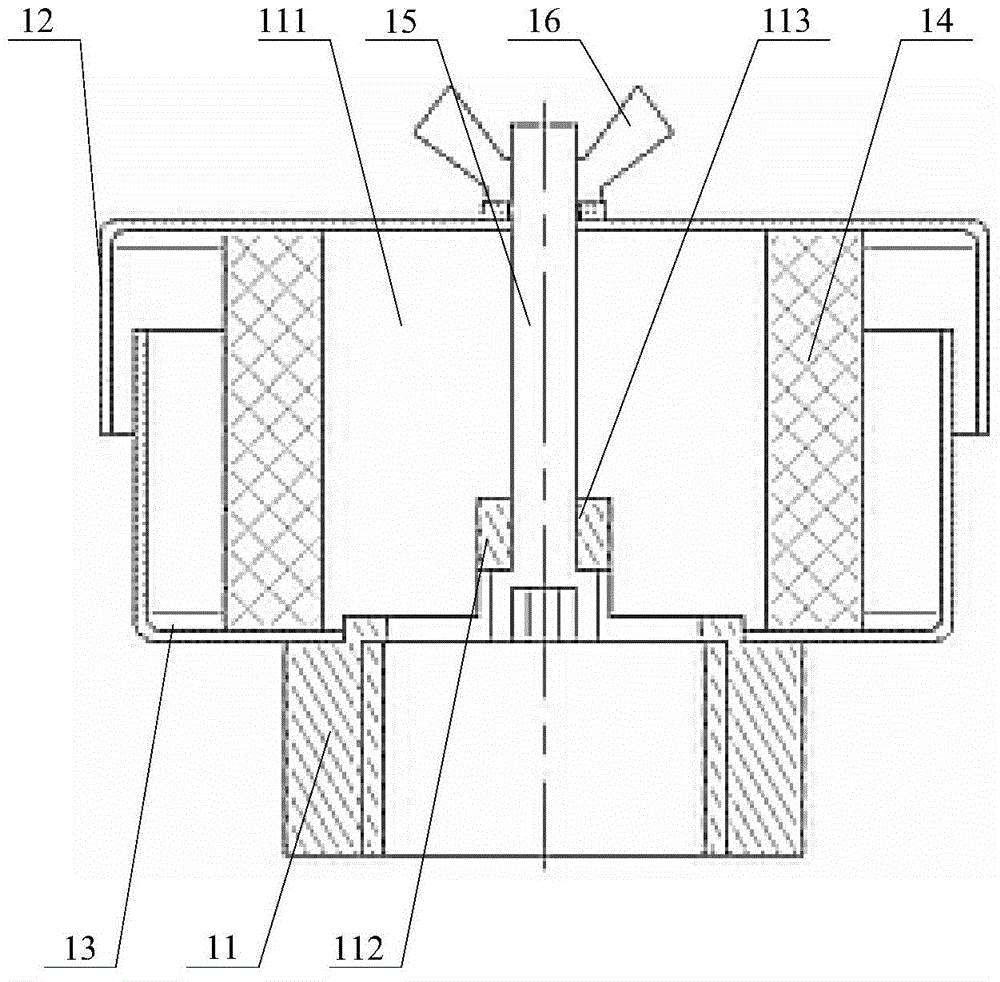

[0015] Please refer to figure 1 , figure 1 It is a cross-sectional view of the assembly structure of the ventilation cap provided by a specific embodiment of the present invention.

[0016] In a specific embodiment, the vent cap provided by the present invention includes a housing 11, and the housing 11 is provided with an upper end cover 12 and a lower end cover 13 that cooperate with each other, and a valve cavity 111 is formed between the upper end cover 12 and the lower end cover 13, A filter element 14 is arranged in the valve cavity 111 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com