Gear shifting mechanism special for automatic transmission

A technology of automatic transmission and shifting mechanism, applied in the direction of shock absorber, shock absorber, mechanical equipment, etc., can solve the problems of high use cost, easy wear and trouble of external teeth, etc., to eliminate wear gap and ensure reliable meshing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

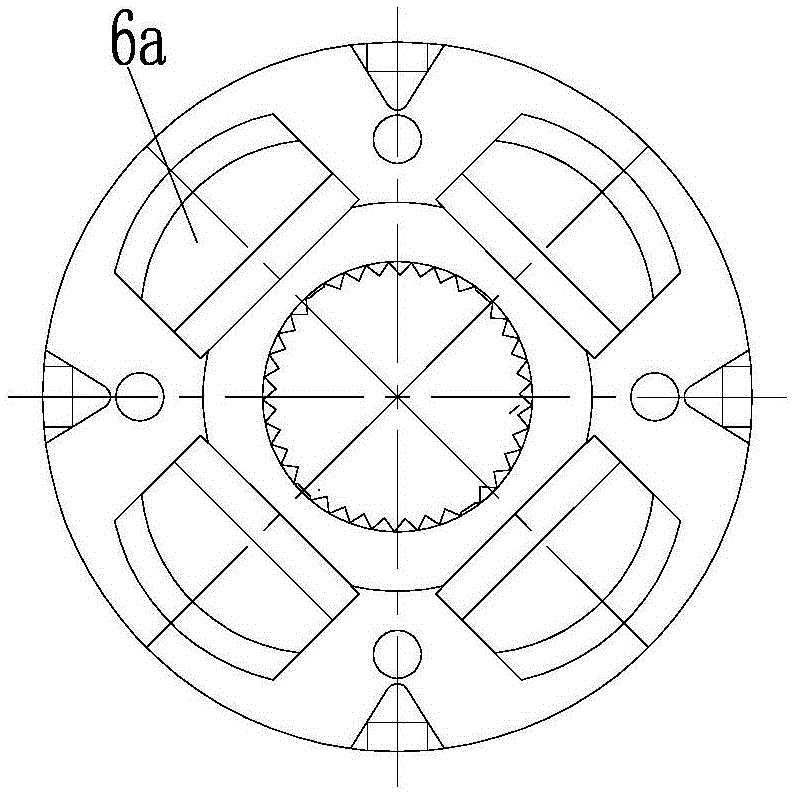

[0014] Such as figure 1 As shown, a shifting mechanism dedicated to automatic transmissions mainly consists of a shifting guide shaft 1, and a first bearing 2, a shifting worm gear shaft gear 3, and a shifting guide shaft 1 that are sequentially set on the shifting guide shaft 1 from left to right. Block guide shaft worm gear 4 and the second bearing 5 are formed. The first bearing 2 and the second bearing 5 are press-fitted on the shift guide shaft 1 for installation at both ends of the shift guide shaft 1 .

[0015] In addition, a torsional shock absorber assembly is set on the shift guide shaft 1 between the shift worm shaft gear 3 and the shift guide shaft worm gear 4 . combine figure 1 — Figure 4 As shown, the torsional shock absorber assembly is mainly composed of a shock absorber left cover 6, a shock absorber right cover 7, a torsional shock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com