Locking and unlocking device for side mold frame of bottle blowing machine

A locking device and bottle blowing machine technology, applied in the field of bottle blowing machinery, can solve the problems of easy tripping of the movable claw, consumption of high pressure gas, easy generation of impact and noise, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

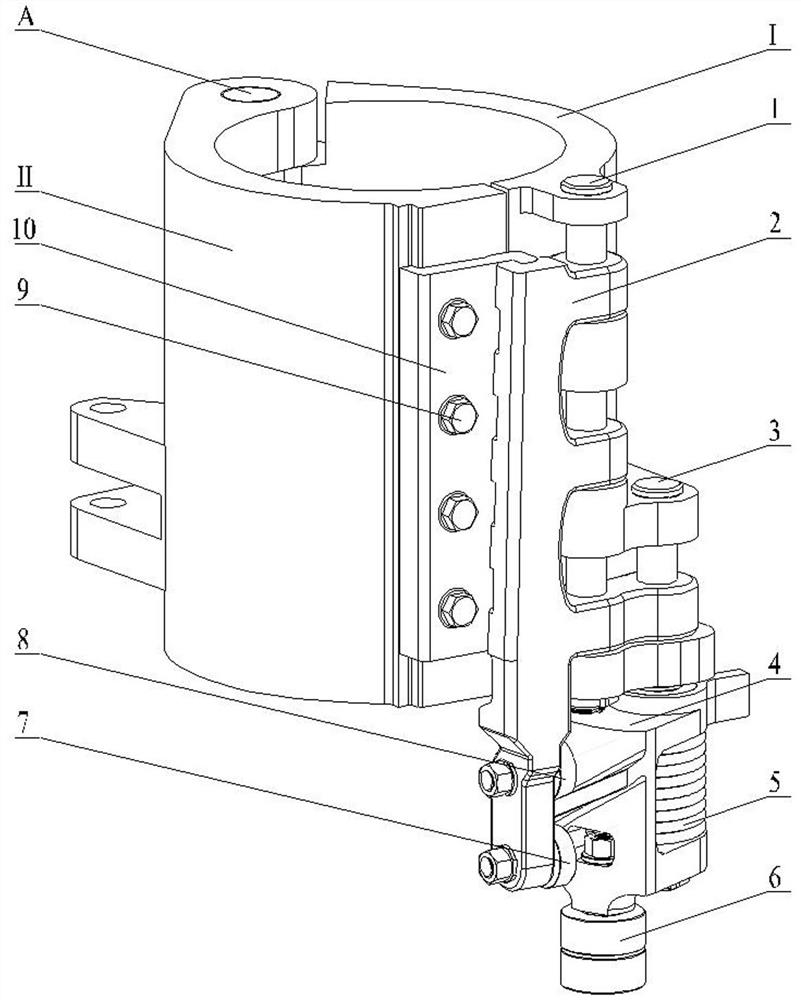

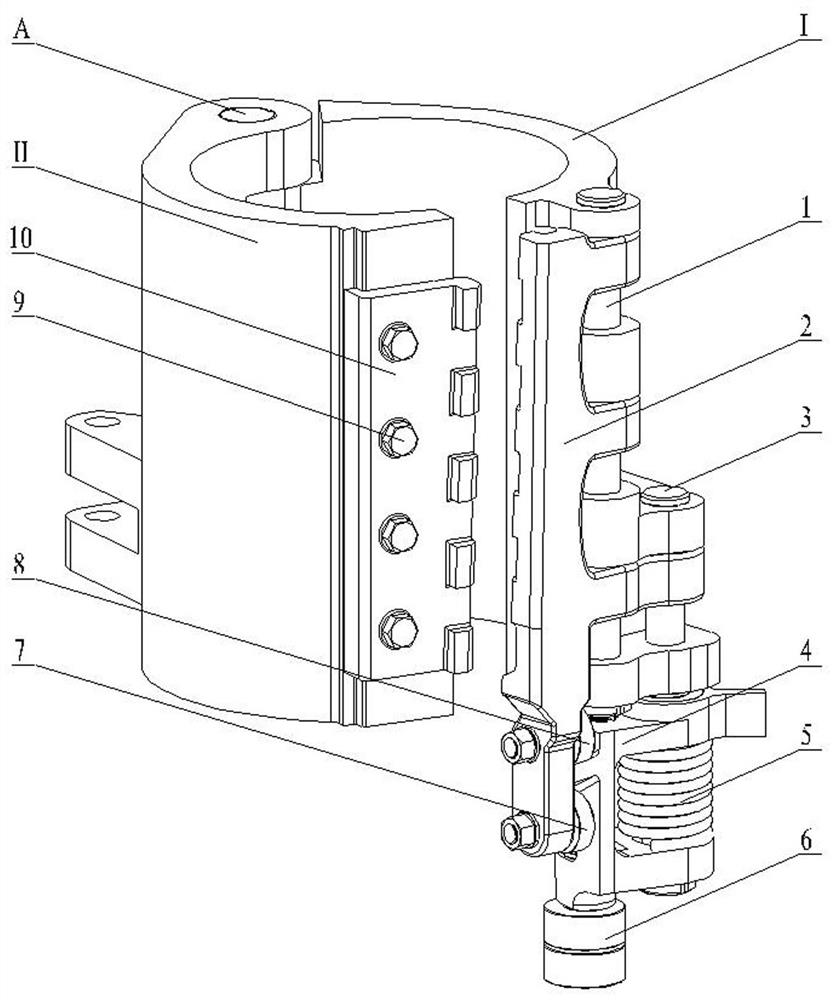

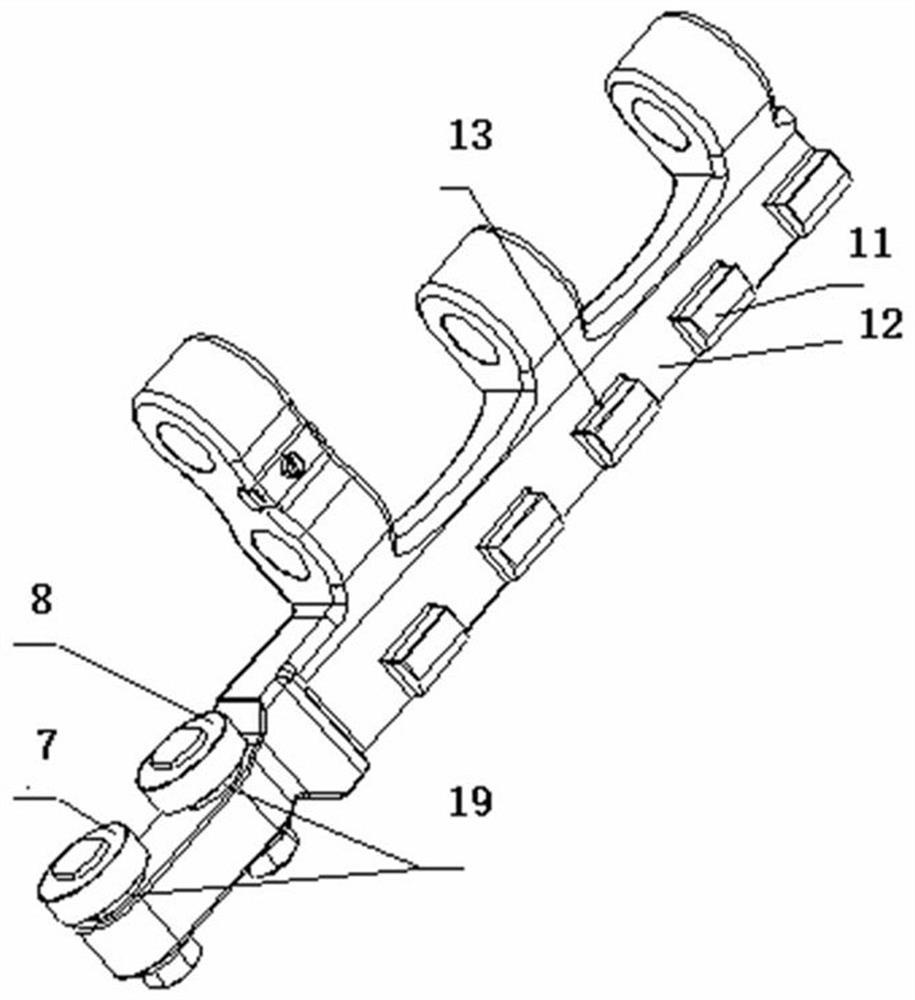

[0033] See attached figure 1 And attached figure 2 , are respectively the structural schematic diagrams of the locked state and the unlocked state of the unlocking and locking device provided in this embodiment; in the forming module for molding plastic blanks into plastic containers by a rotary blow molding machine, two subdivisions for supporting plastic containers The two side mold frames I and II of the side mold (not shown) rotate around the opening and closing rotation axis A of the side mold frames on the molding module frame (not shown). The main column 1 and the auxiliary guide pile 3 are fixedly connected with the side formwork frame I, and the axis of the guide column is parallel to the axis of the axis A. The two guide post holes on the movable buckle 2 cooperate with the main pillar 1 and the auxiliary guide pillar 3 respectively to form a moving pair, so that the movable buckle 2 can move up and down relative to the side formwork I along the guide pillar (that ...

Embodiment 2

[0047] This embodiment adopts the technical solution provided by embodiment 1, and the difference from embodiment 1 is that the load-bearing tooth surfaces of the movable buckle and the fixed buckle have the following tooth surface characteristics.

[0048] See attached Figure 8 , is a schematic diagram of tooth surface features of the movable buckle and the fixed buckle of the opening and closing device of this embodiment. The movable buckle bearing tooth surface 13 of the movable buckle is a cylindrical surface, and the straight generatrix of each tooth surface forms a fixed angle α with the moving direction B of the movable buckle (that is, the axial direction of the axis A), and each tooth surface The vertical direction is offset from each other by a distance; the fixed buckle bearing tooth surface 16 of the fixed buckle is a cylindrical surface, and the straight generatrix of each tooth surface also forms a fixed angle α with the moving direction B of the movable buckle ...

Embodiment 3

[0050] This embodiment adopts the technical solution provided by Embodiment 1, and the difference from Embodiment 1 is that the load-bearing tooth surfaces of the movable buckle and the fixed buckle have the tooth surface characteristics as described below.

[0051] See attached Figure 9 , is a schematic diagram of the tooth surface characteristics of the movable buckle and the fixed buckle of the opening and closing lock device provided in this embodiment; the tooth surfaces 13 of the movable buckle of each tooth of the movable buckle are coplanar, and the straight generatrices of the tooth surfaces are parallel to the moving direction of the movable buckle, That is, α=0°; the tooth surface 16 of the fixed buckle of each tooth of the fixed buckle is also coplanar, and the straight generatrix of the tooth surface is also parallel to the moving direction of the movable buckle, that is, α=0°. Since there is no wedge angle on the load-bearing tooth surface, this example cannot r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com