Automatic-pressurizing seal butterfly valve

A self-filling, butterfly valve technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of not widely used in practice, complex structure, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

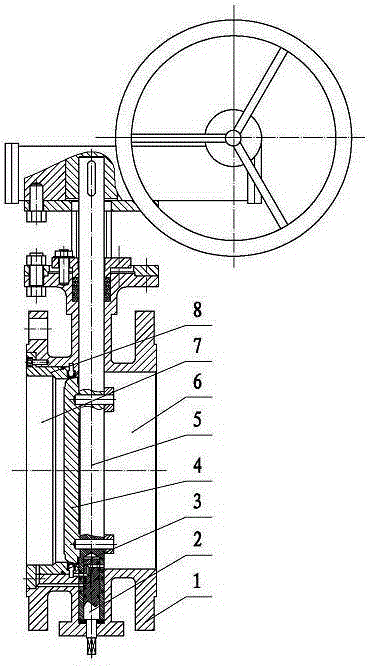

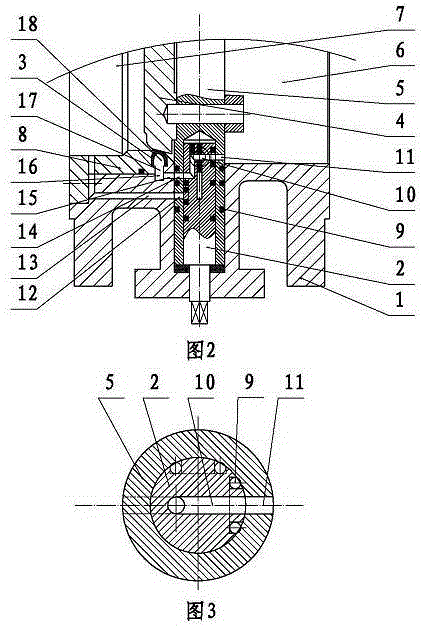

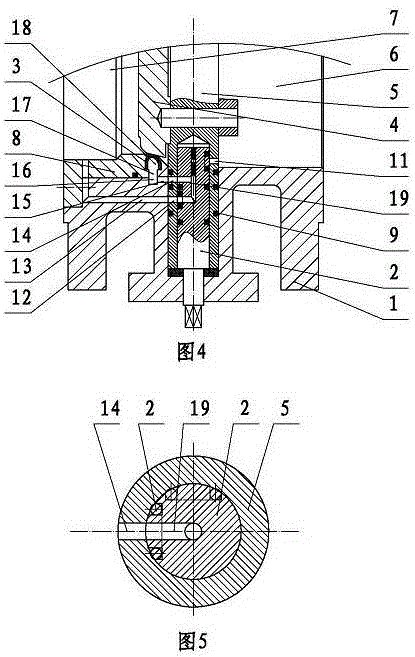

[0022] exist figure 1 In the self-pressurized sealing butterfly valve shown, the valve body 1 is a casting, and the right chamber of the valve body 1 is the valve body inlet 6, and the valve body inlet 6 communicates with the inlet pipe through the flange of the orifice. The left chamber of the valve body 1 is the valve body outlet cavity 7, the valve body outlet cavity 7 communicates with the liquid outlet pipeline through the flange of the orifice, and passes through the valve body on the upper side of the valve body 1 in the middle of the valve body 1 The valve stem 5 is installed on the wall, and the valve stem 5 is rotatably supported on the upper and lower valve body walls of the valve body 1. The valve stem 5 is driven by the worm gear mechanism outside the valve body 1 through the hand wheel, and the valve body 5 is fixedly connected with a valve. Disc 4, the valve disc 4 is disc-shaped, the valve disc 4 rotates with the valve stem 5 to open and close the valve, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com