Switching valve and control method thereof

A control method and technology for switching valves, applied in valve details, valve devices, multi-way valves, etc., can solve problems such as high precision requirements, out-of-step, high production costs and material requirements, achieve high precision, low cost, and avoid failures step problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

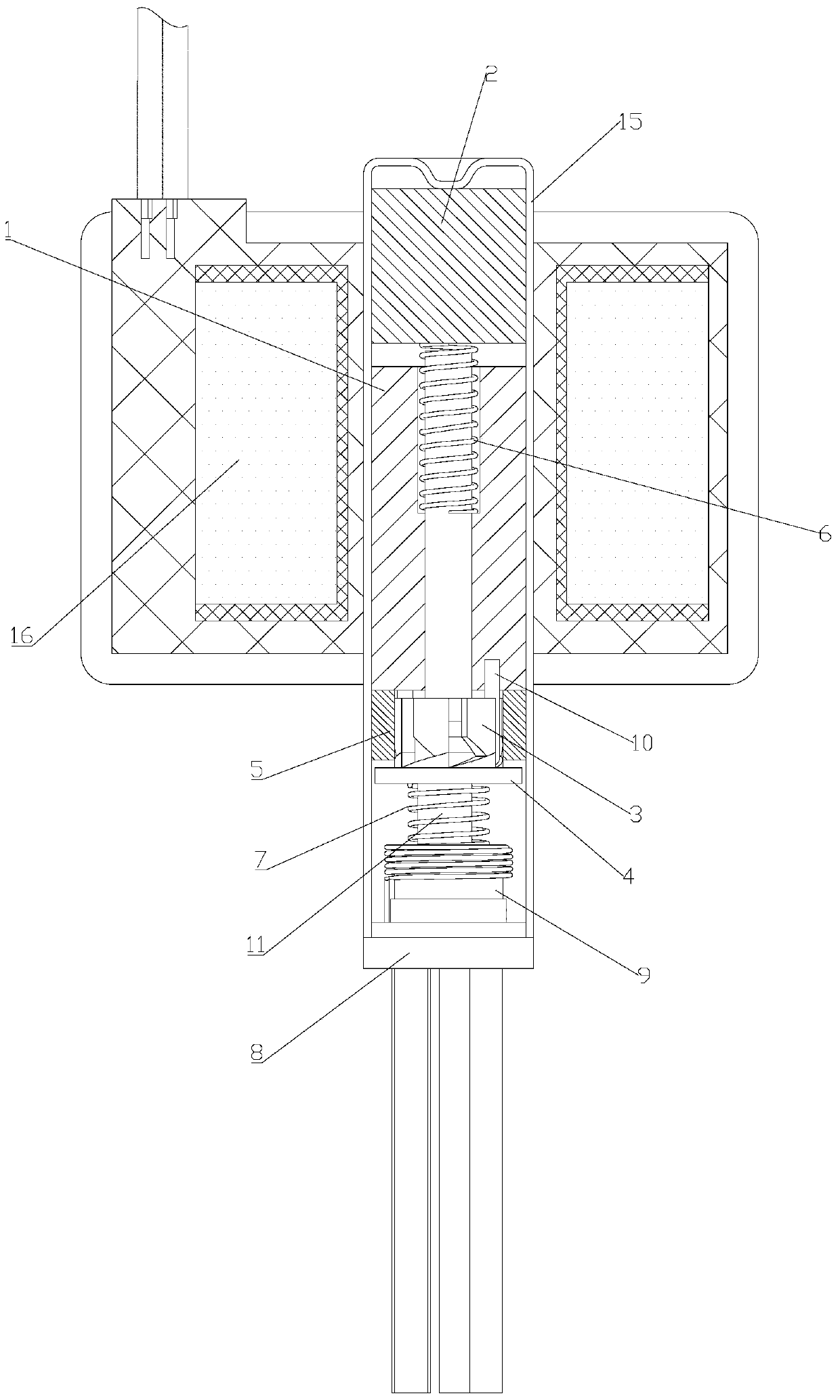

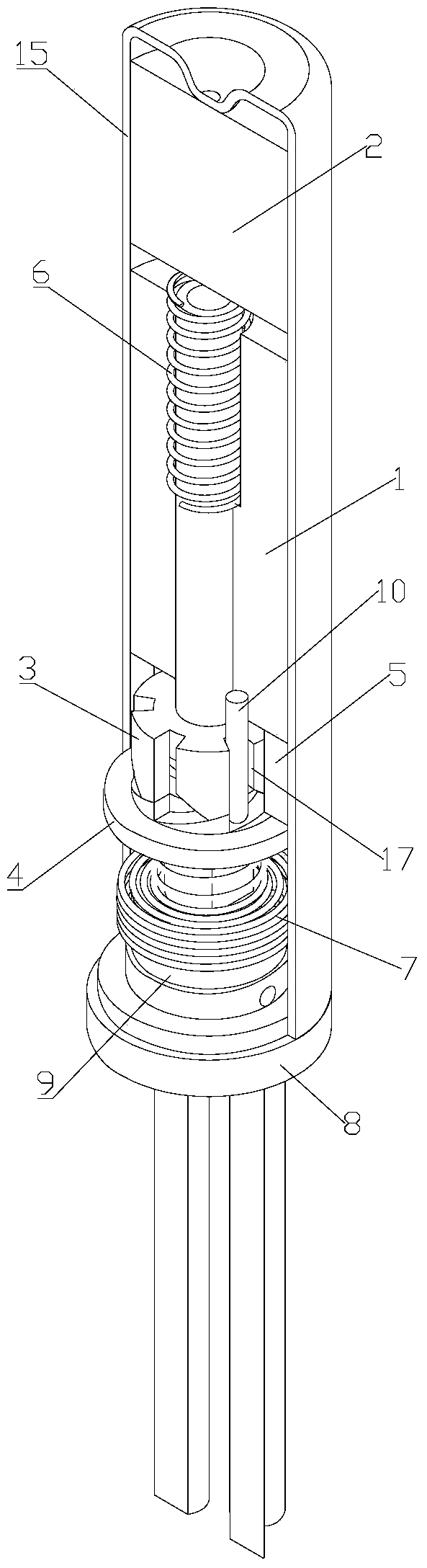

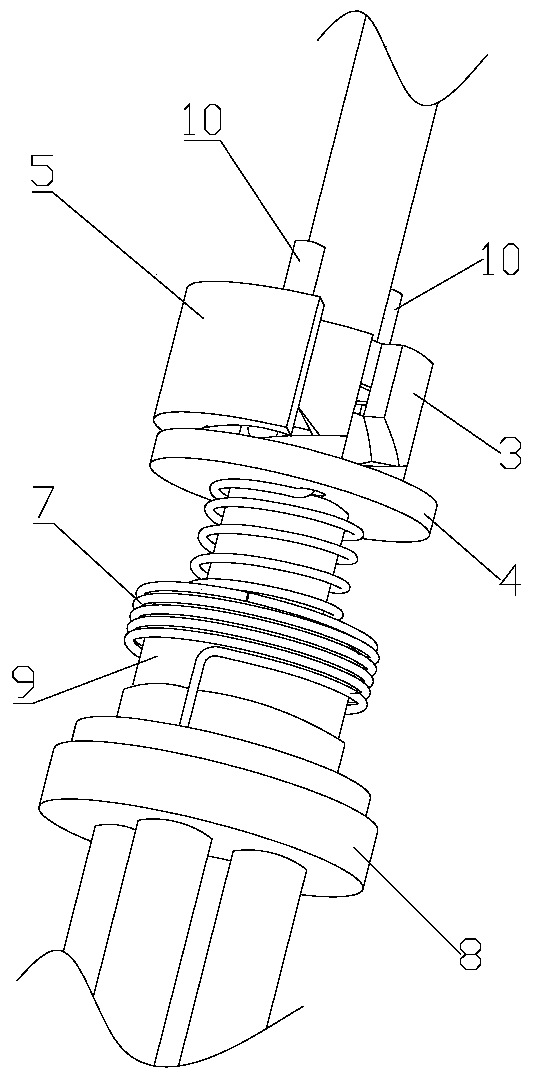

[0024] As a first aspect of the invention, please refer to Figure 1 to Figure 7 , provides a switch valve, in particular, can be a four-way valve pilot valve, including: electromagnetic drive device; anti-reverse ratchet device, used for the axial drive of the electromagnetic drive device, the output along the electromagnetic drive The device rotates in the circumferential direction and rotates the first predetermined angle; the reset device is coupled with the output end of the ratchet device, and is used to return the ratchet device to the initial state along the circumferential direction of the electromagnetic drive device; the valve port switching device is in the rotational movement The switching of the valve port is realized under the driving.

[0025] When in use, the present invention adopts the principle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com