An online monitoring device and method for pm2.5 industrial flue gas

A PM2.5 and monitoring device technology, applied in the field of PM2.5 capture, can solve problems such as low accuracy and resolution, inability to meet the requirements of PM2.5 filtration, and inapplicability to industrial applications, so as to achieve intelligent The effect of chemical control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

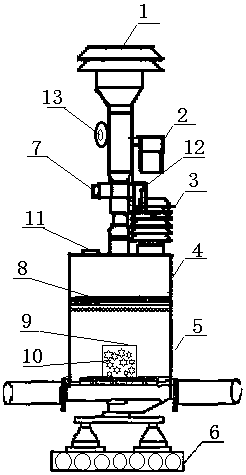

[0027] An online monitoring device and method for PM2.5 industrial flue gas, including a detection head (1), an integrated sensor (2), a layered isolation room, a PM2.5 detection unit (10), a central processing unit (3), The guide rail crawler (6), GPRS communication module (11) and external display operation panel integrate the smoke detection module and the online monitoring module, supported by the guide rail crawler (6) and inside the flue gas pipe and dust removal box Walking, the GPRS communication module (11) can measure its coordinate point by positioning, the detection head (1) is exposed to the flue gas channel at different heights for sampling, and the integrated sensor (2) detects the flue gas temperature initially detected by the detection head , humidity, flow direction, flow velocity, air pressure and chemical composition, the layered isolation room is divided into the first layered isolation room (4) and the second layered isolation room (5) through the PM2.5 cu...

Embodiment 2

[0034] A method for operating an on-line monitoring device for PM2.5 industrial flue gas, characterized in that continuous on-line monitoring and intelligent automatic adjustment are performed, and the steps are as follows:

[0035] (1) The online monitoring device can be distributed in each section inside the flue gas pipeline and the dust removal box or walk inside the flue gas pipeline and the dust removal box through the crawler guide rail (6);

[0036] (2) Use the GPRS communication module (11) to locate and measure the coordinate point where it is located, through the sampling of the detection head (1) and the detection of the integrated sensor (2), the temperature, humidity, flow direction, flow velocity, Air pressure and chemical composition; through the scattered light collector (12) to capture the particle pulse signal converted from light intensity and the transient image of the flow field taken by the PIV camera (13), the distribution of the flow field at the corres...

Embodiment 3

[0042] A method for operating an on-line monitoring device for PM2.5 industrial flue gas, characterized in that continuous on-line monitoring and intelligent automatic adjustment are performed, and the steps are as follows:

[0043] (1) The online monitoring device can be distributed in each section inside the flue gas pipeline and the dust removal box or walk inside the flue gas pipeline and the dust removal box through the crawler guide rail (6);

[0044] (2) Use the GPRS communication module (11) to locate and measure the coordinate point where it is located, through the sampling of the detection head (1) and the detection of the integrated sensor (2), the temperature, humidity, flow direction, flow velocity, Air pressure and chemical composition; through the scattered light collector (12) to capture the particle pulse signal converted from light intensity and the transient image of the flow field taken by the PIV camera (13), the distribution of the flow field at the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com