High Density Splice Fiber Distribution Tray

A high-density, splicing disk technology, applied in light guides, optics, instruments, etc., can solve the problems of poor versatility, single function, and small storage space, and achieve the effects of small space occupation, expanded capacity, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

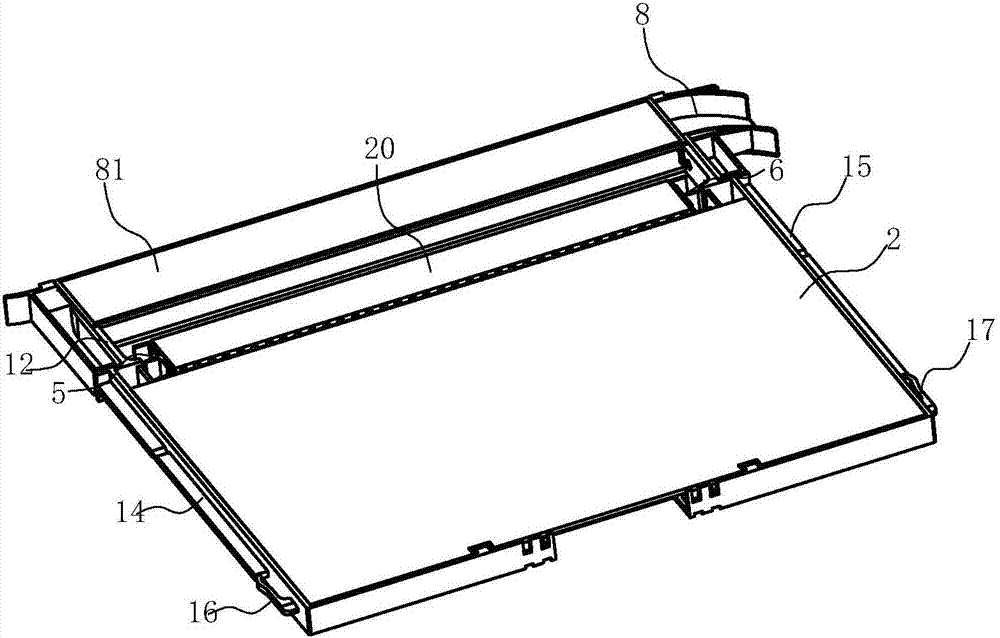

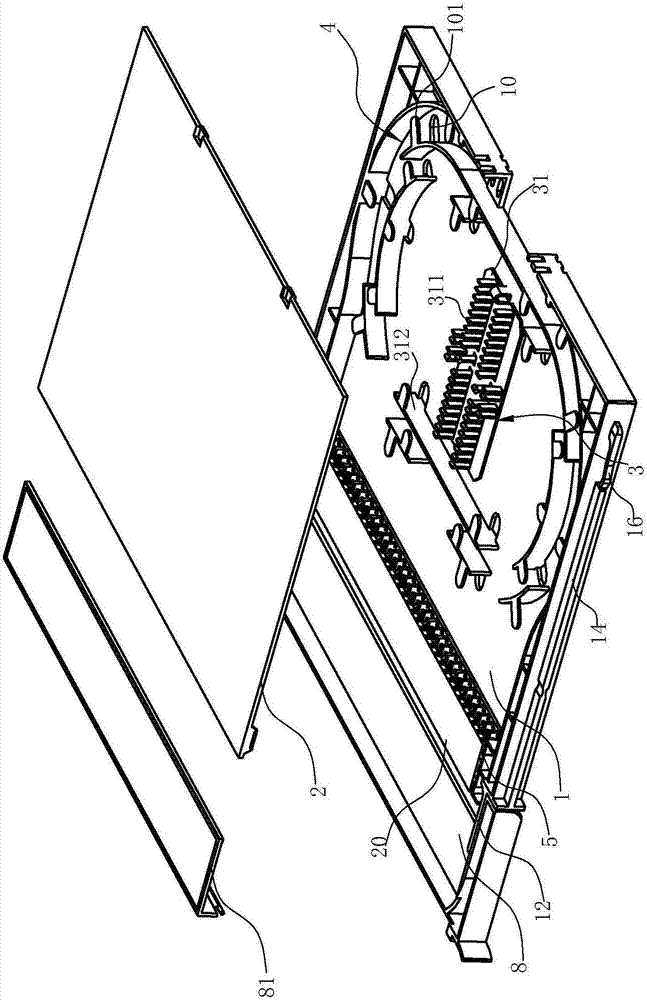

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

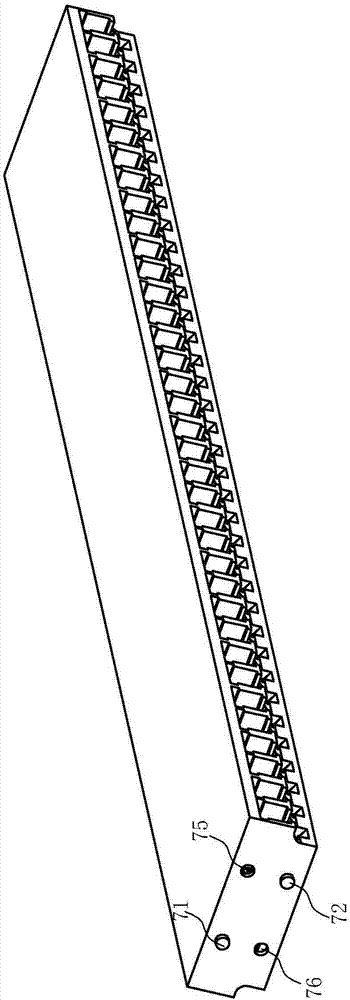

[0028] Such as Figure 1-11As shown, the high-density fusion splicing fiber distribution tray includes a base 1 and a cover plate 2. The side wall of the base 1 is surrounded to form a cavity 11. The cover plate 2 can cover the cavity 11. The base 1 and the cover plate 2 form a cavity 11. The accommodating space accommodates a fusion splice tray 3 and a wiring tray 4 at the same time. The central part of the base 1 is provided with a fusion splice tray 3. The center of the fusion splice tray 3 has a fusion splice seat 31 for welding optical fibers and pigtails, and the fusion splice seat 31 has 24 cores or 36-core card slot 311, and the fusion splice seat 31 has a wire slot 312 for cables to pass through, and the distribution board 4 is arranged on the outer periphery of the fusion splice tray 3 and formed with a fiber storage area. The fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com