Device for automatically producing electric blanket

A technology for automatic production and electric blankets, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problem that electric blankets cannot be processed and produced, and achieve the effect of improving market competitiveness, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

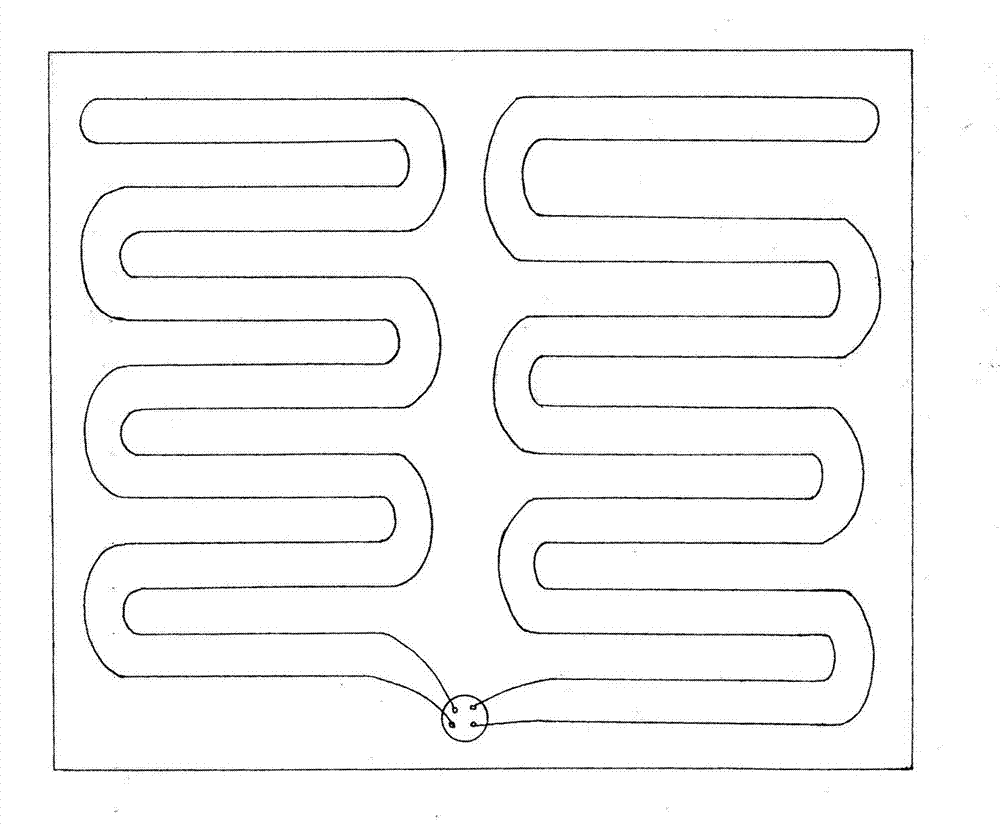

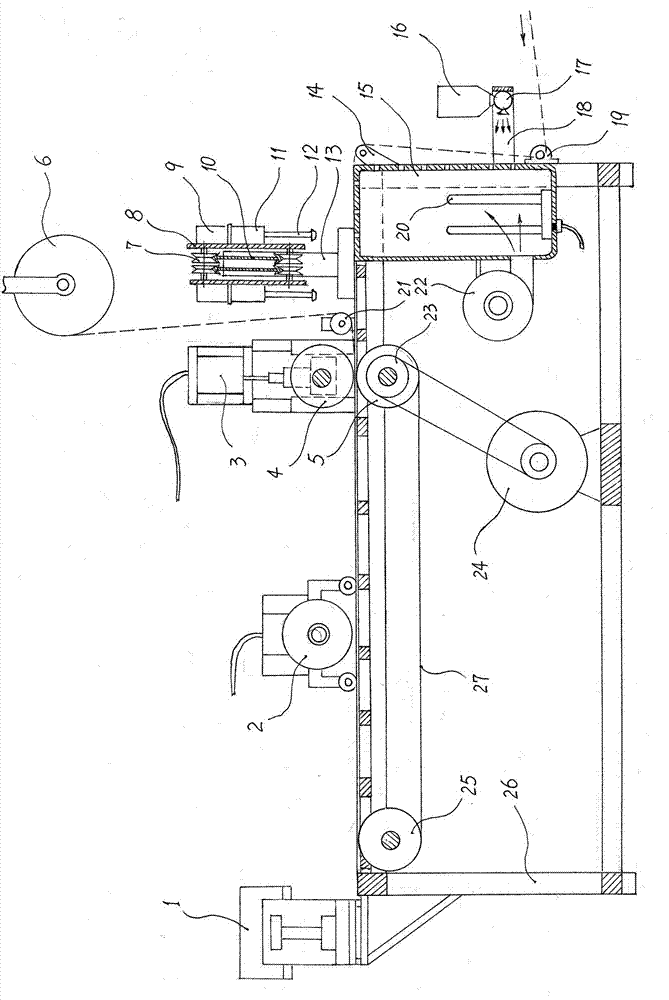

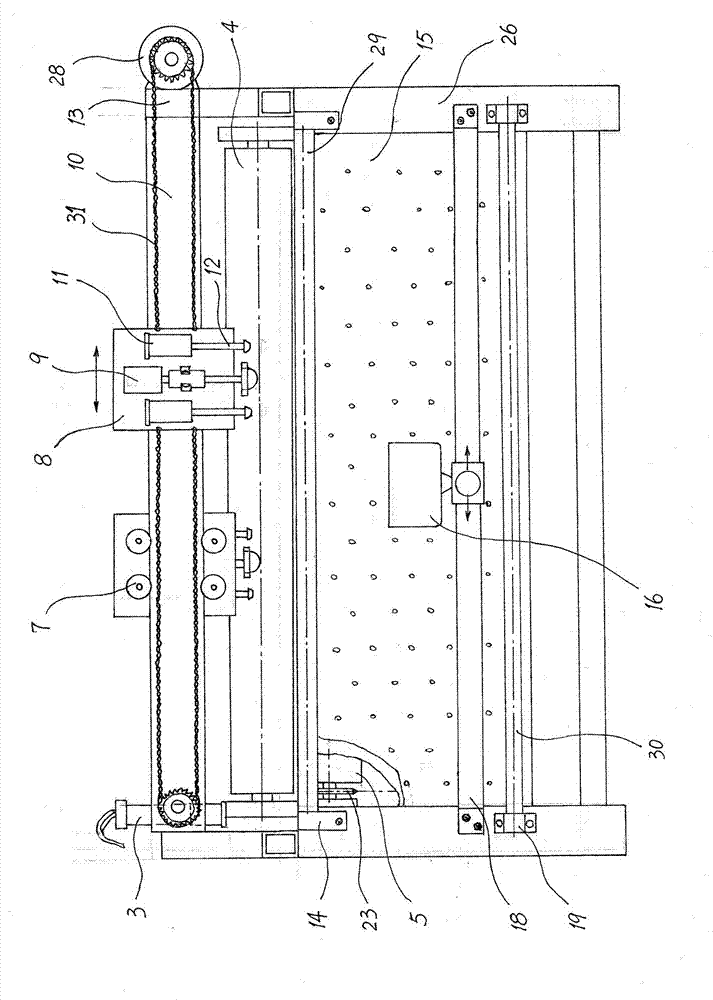

[0021] Such as figure 1 , figure 2 As shown, the frame 26 is a rectangular parallelepiped steel frame structure. A lower layer cloth guiding mechanism for guiding the lower layer cloth is provided on the front end side of the frame 26 . This lower cloth guide mechanism comprises an upper guide shaft 29 and a lower guide shaft 30; wherein, the upper guide shaft 29 supports and is connected to the upper part of the frame 26 front end side by the upper shaft bracket 14; the lower guide shaft 30 passes through The lower pedestal 19 is supported to be connected to the bottom of the front end side of the frame 26 . Underlayer Cloth ( figure 1 The dotted line part at the right end of the frame) bypasses the lower guide shaft 30 and the upper guide shaft 29 respectively, and is continuously brought to the top surface of the frame 26 by the press-fit transmission mechanism at the top of the frame.

[0022] On the front end side of the frame 26, a glue spraying mechanism for contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com