Method for fill level measurement using the travel time principle

A technology of filling level and travel time, applied in the direction of measuring device, liquid/fluid solid measurement, engine lubrication, etc., can solve problems such as large measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

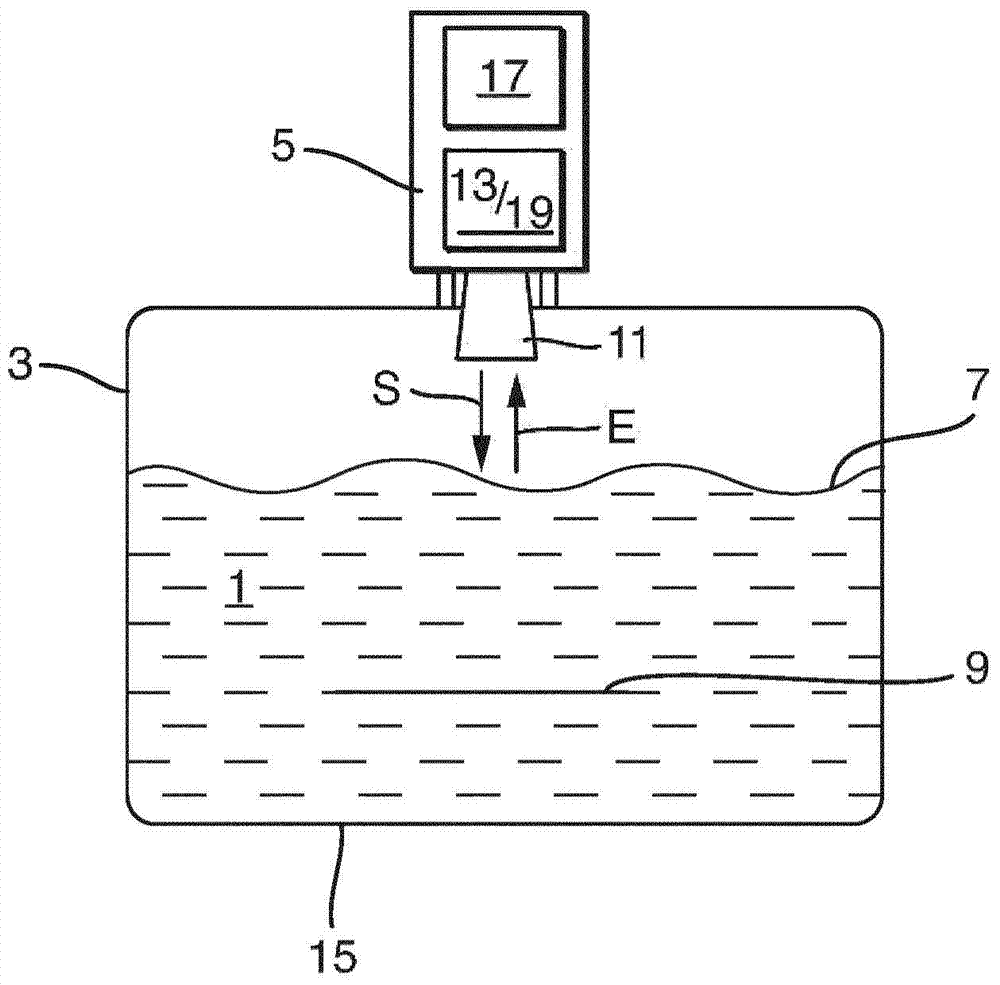

[0078] figure 1 An example of an arrangement for fill level measurement to which the method of the invention is applicable is shown. The arrangement comprises a container 3 filled with a filling substance 1 on which a filling substance measuring device 5 operating according to the travel time principle is arranged. Suitable fill-level measuring devices 5 are, for example, microwave-operating fill-level measuring devices or ultrasonic-operating fill-level measuring devices. The fill level measuring device 5 serves to measure the fill level L of the fill substance 1 in the container. For example, a disturbance 9 is introduced in the container 3 . Disturbances 9 can be eg objects installed in container 3, stirring mechanisms and of course any other structure on which reflections can occur. Here only a single disturbance 9 is provided for easier understanding and clarity. Of course, in actual measurement situations, there may be many disturbances.

[0079] For example, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com