Fire fighting truck

A technology for fire trucks and car bodies, which is applied in fire rescue and other fields. It can solve the problems of insufficient atomization of dry powder, poor fire extinguishing effect, and low concentration of dry powder, and achieves the effects of easy fire extinguishing, enhanced atomization effect, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

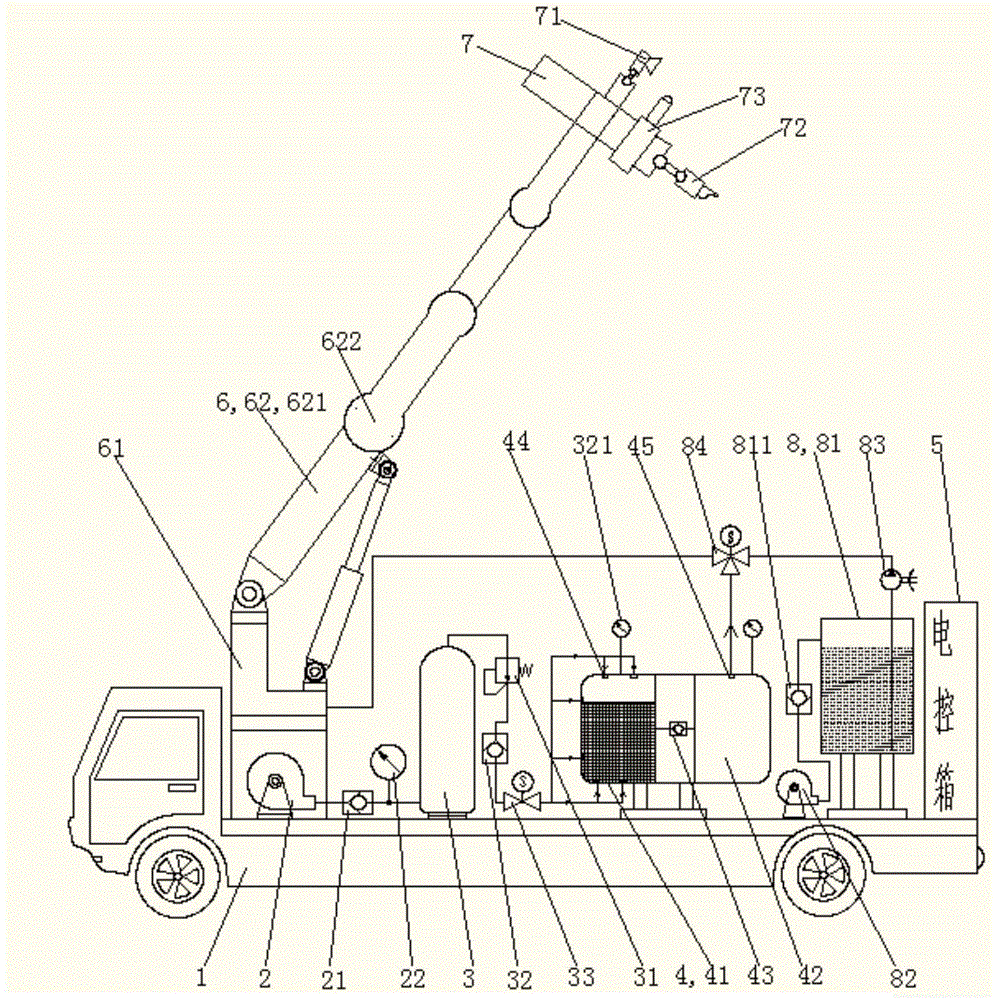

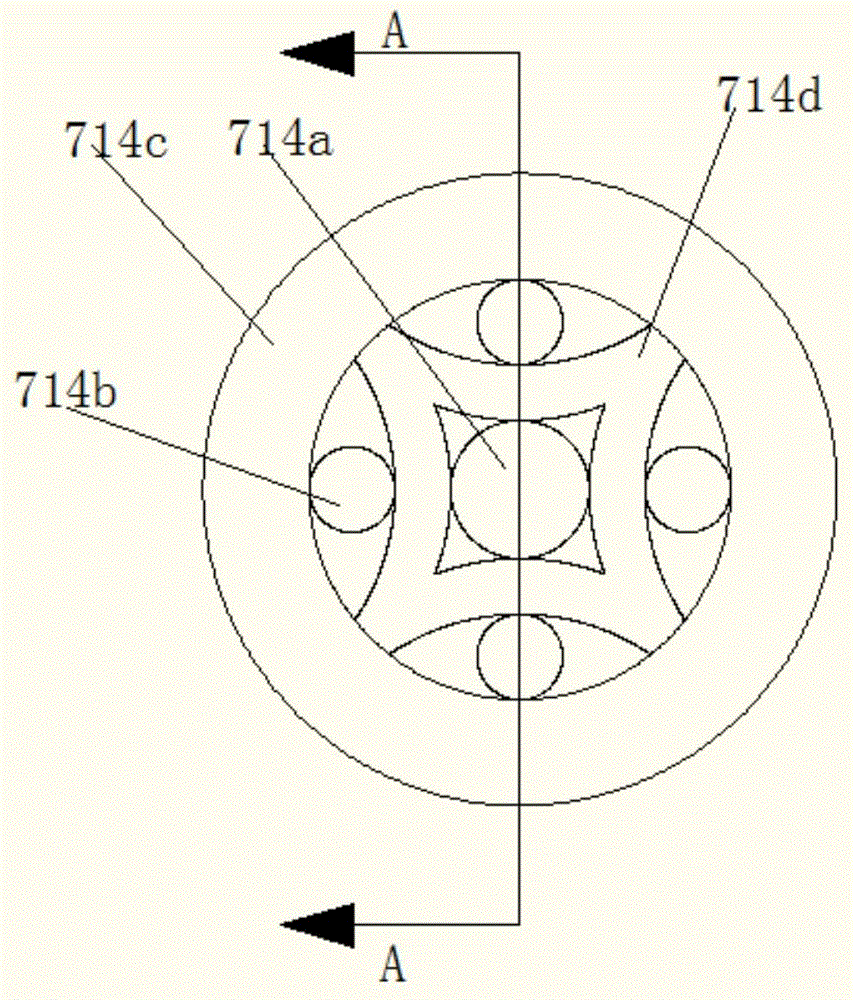

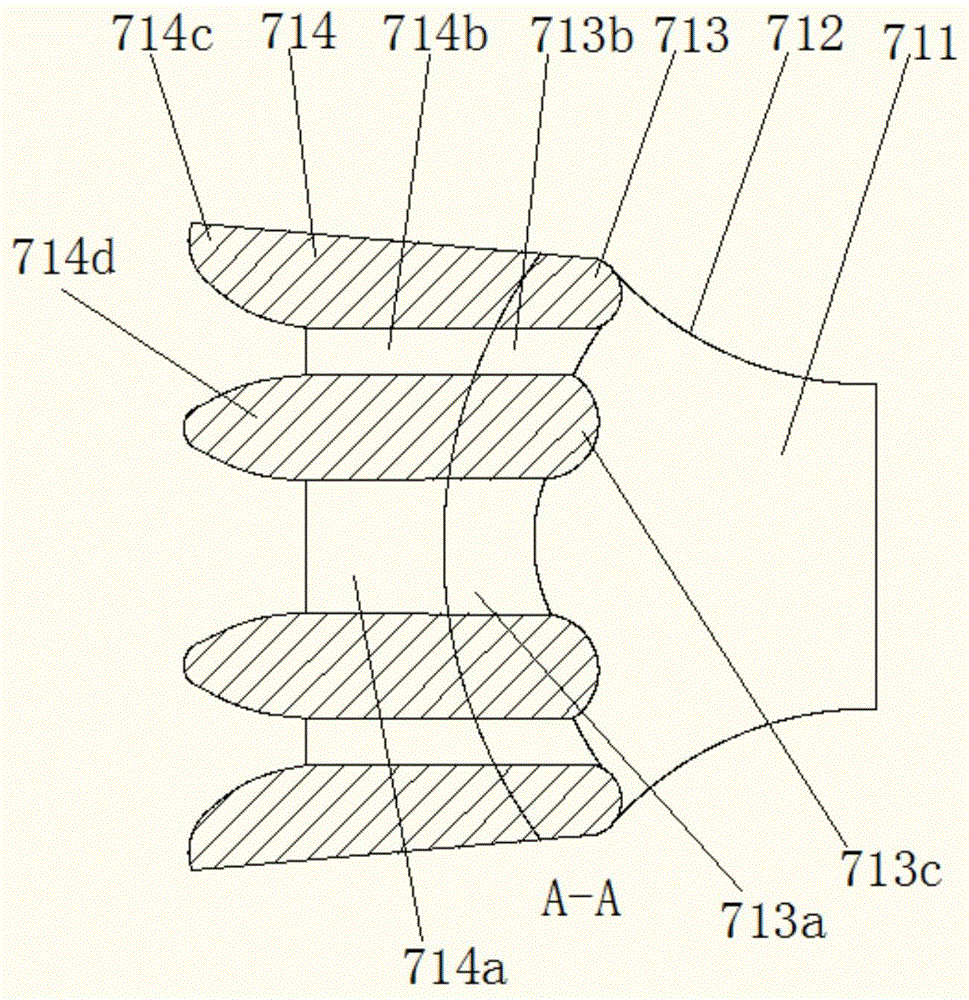

[0020] refer to Figure 1 to Figure 3 A kind of fire truck shown, it comprises car body 1 and the high-pressure air pump 2 that is arranged on car body 1, high-pressure gas storage tank 3, dry powder tank 4, electric control box 5 and the controllable output that is controlled by electric control box 5 Feeding device 6, the gas output end of the high-pressure air pump 2 is connected with the high-pressure gas storage tank 3 through the gas pipeline, and the gas pipeline is provided with a check valve 21 and a pressure gauge 22, and the high-pressure gas storage tank 3 is connected with the dry powder tank 4 through the gas pipeline. A gas inlet 44 is connected, and the dry powder tank 4 includes a gas-powder mixing part 41 and a throttle release part 42. A gas channel is provided between the gas-powder mixing part 41 and the throttle release part 42, and a gas-powder mixing part is arranged in the gas channel. 41 leads to the electronically controlled one-way valve 43 of the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap