Pipe network type ultra-fine dry powder extinguisher

A technology of ultra-fine dry powder and fire extinguishing device, used in fire rescue and other directions, can solve the problems of small protection area, short spray duration, short spray distance, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

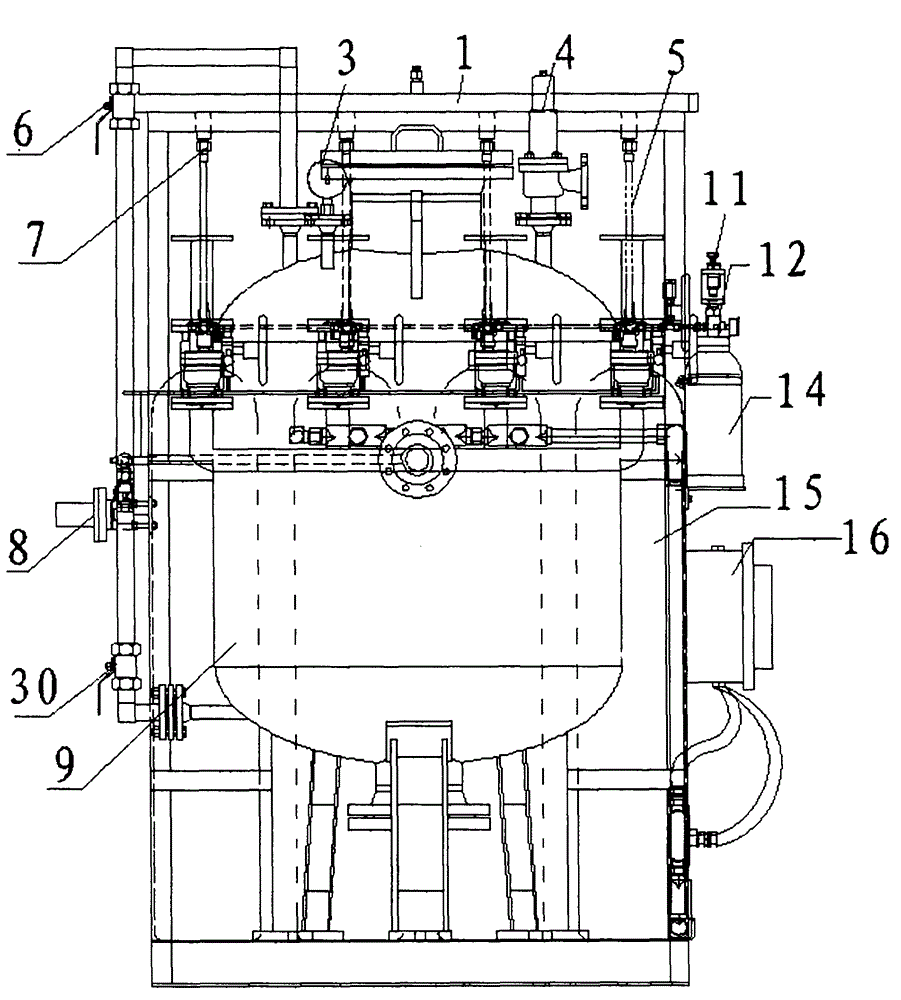

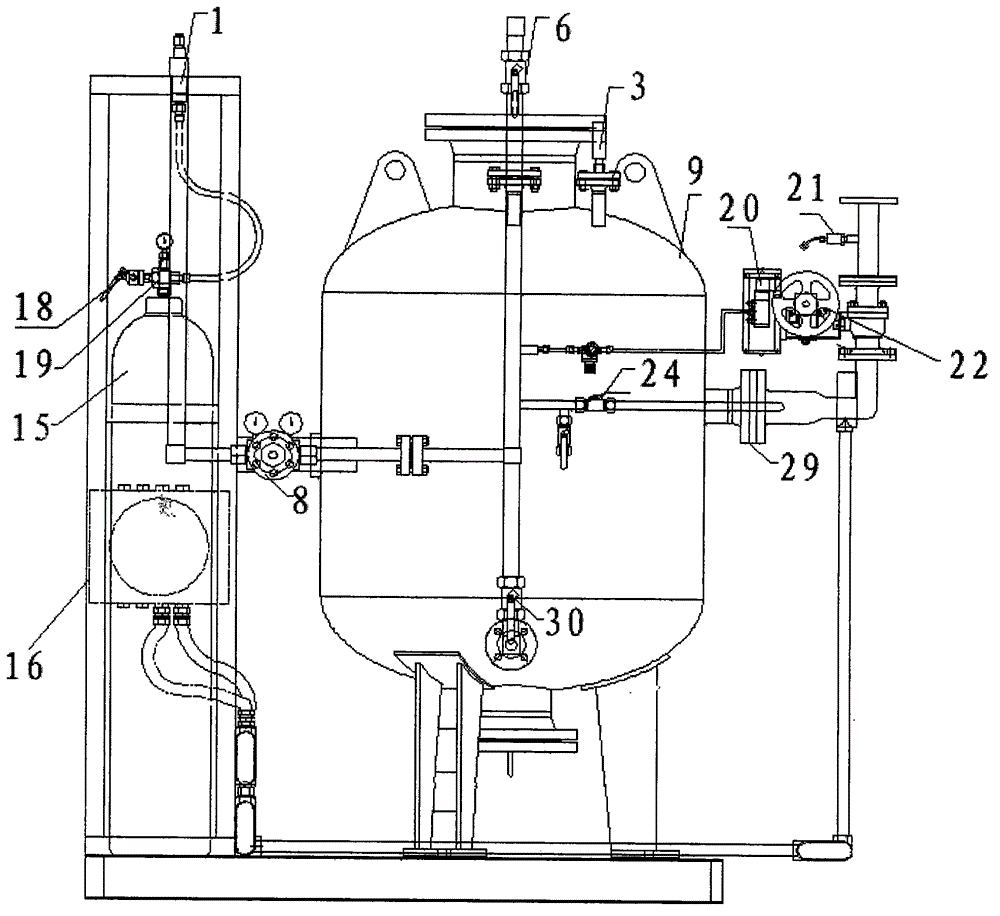

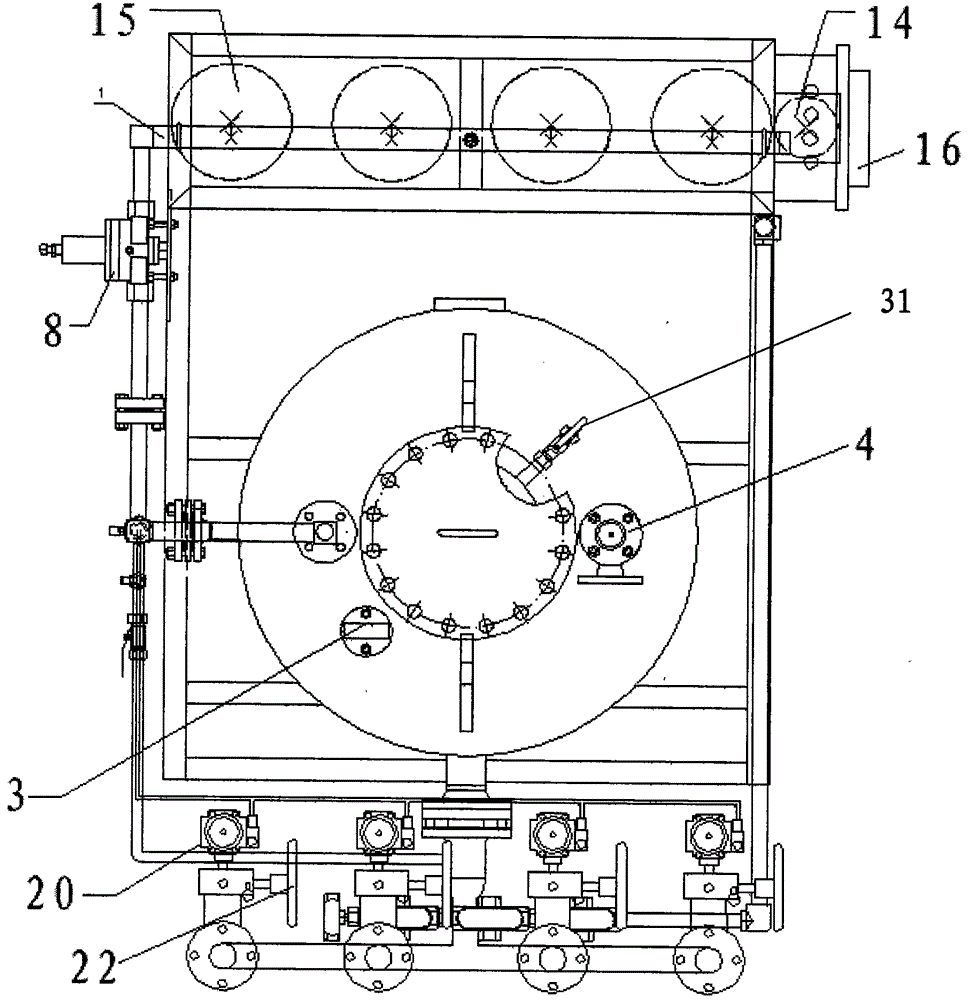

[0020] Such as Figure 1-Figure 3 As shown, the pipe network type ultra-fine dry powder fire extinguishing device includes an ultra-fine dry powder storage tank 9, a control box 16 that can receive the signal of the fire-fighting host computer, and the outlet of the ultra-fine dry powder storage tank 9 is provided with a release diaphragm 29, and the release diaphragm 29 passes through the pipeline. Connect to the partition selection valve 20, and the partition selection valve 20 is connected to the eruption pipeline. In this embodiment, there are 4 partition selection valves. Also comprise starting bottle 14 and driving bottle 15, in the present embodiment, be provided with 4 driving bottles, inert gas is all housed in starting bottle 14 and driving bottle 15; Starting bottle 14 is provided with first bottle head valve 12 and controllable The electromagnetic pilot valve 11 of the first bottle head valve 12, the first bottle head valve 12 is located at the bottle mouth positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com