Contact rear sleeve riveting tool

A technology for riveting tooling and contact parts, which is applied in the field of riveting tooling for the back cover of the contact part for connectors, and can solve problems such as low reliability, poor consistency of the contact parts, and the inability of crimping pliers to achieve the effect of riveting the contact end and the back cover. , to achieve the effect of stable and precise movement and improve versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

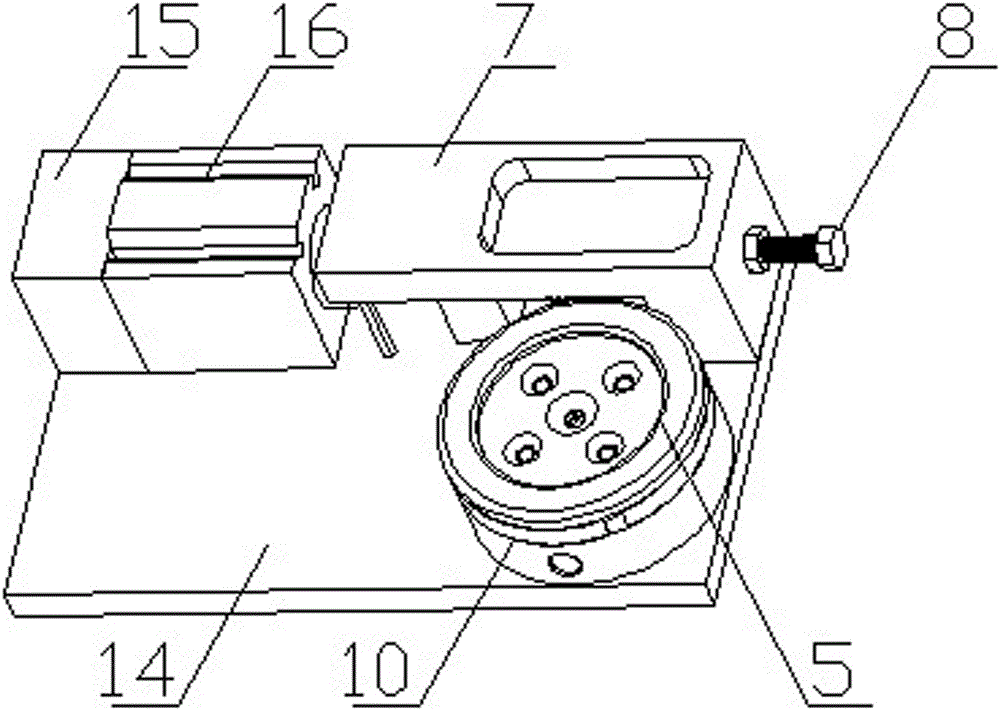

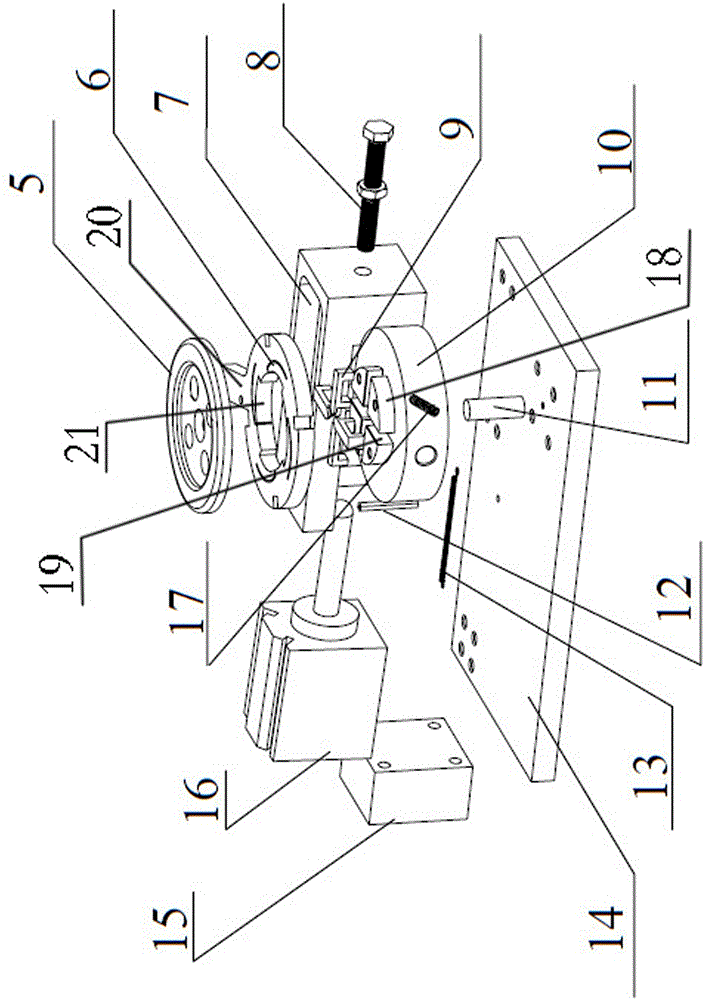

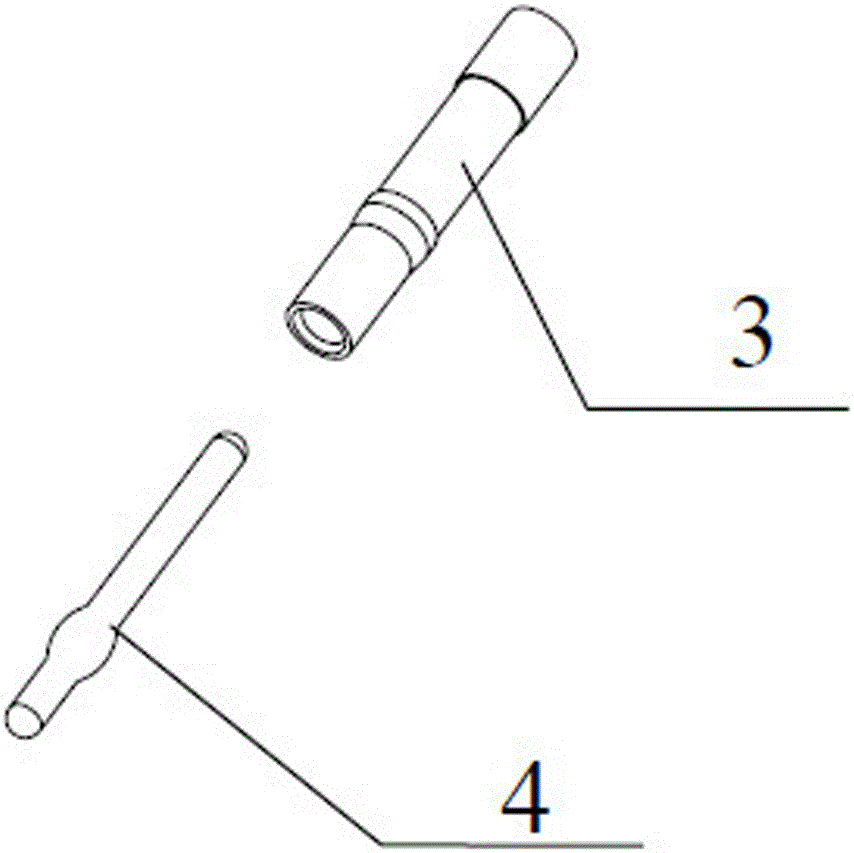

[0015] As shown in the figure, a riveting tool for the rear cover of a contact piece includes a base 14 on which a cylinder 16 and a riveting device are installed. There is a positioning through hole, and a positioning block 11 is movably installed in the positioning through hole, and the bottom of the positioning block 11 is supported by the base. The top surface of the slider round seat 10 is provided with a cylindrical boss 18 coaxial therewith, and the cylindrical boss 18 is provided with a horizontal cross groove 19 through which the center of the cross groove 19 communicates with the positioning through hole correspondingly. Four slide blocks 9 that cross are placed, the head of the slide block 9 is a pointed top, the tail of the slide block 9 is an arc surface and the tail of the slide block 9 stretches out of the cylindrical boss 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com