Motorcycle oil tank equipment

A technology for motorcycles and fuel tanks, applied in gasoline drums, bicycle accessories, transportation and packaging, etc., can solve problems such as inconvenience, occupying cargo space, and increasing the amount of one-time refueling. effect of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

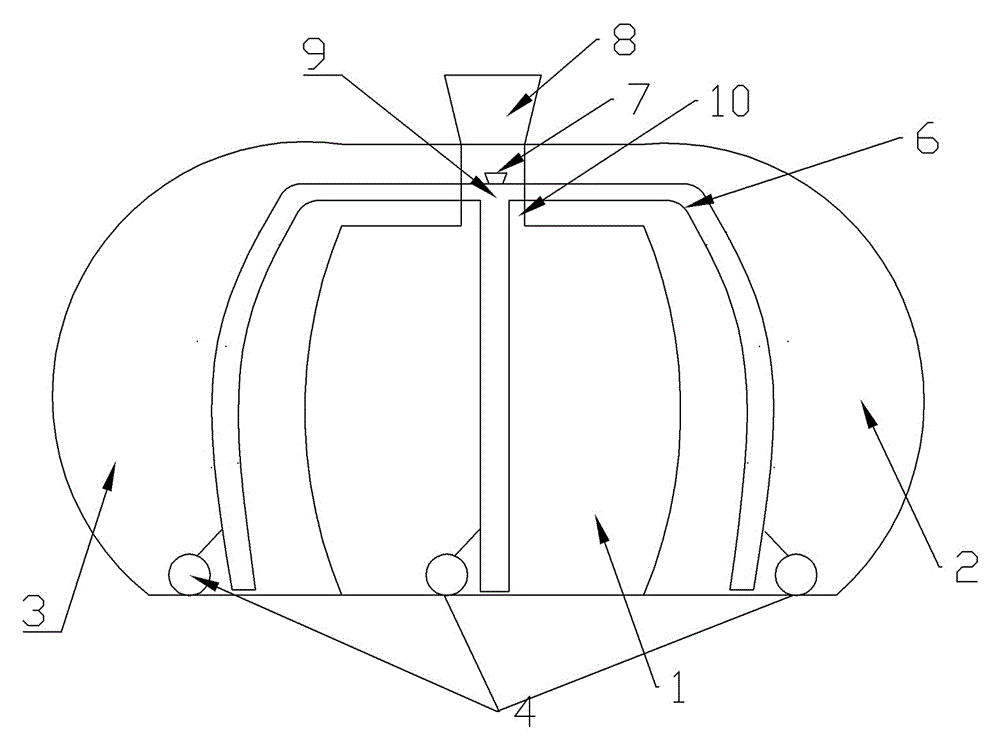

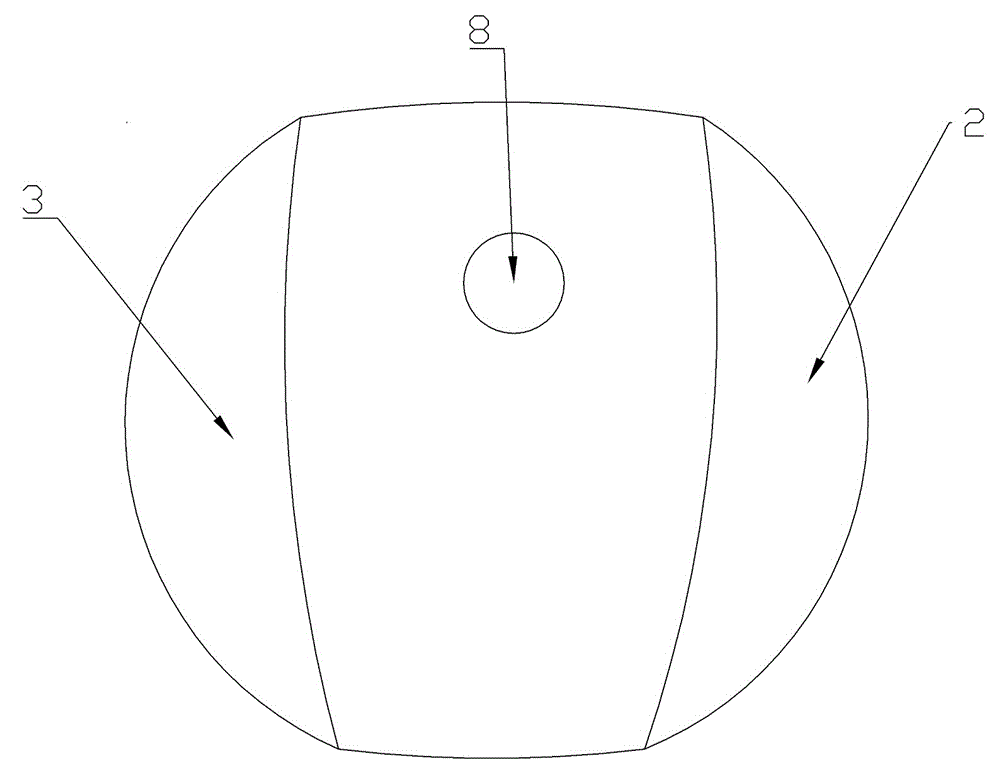

[0015] Motorcycle oil tank equipment of the present invention, as figure 1 , figure 2 As shown, including the main fuel tank 1, the bottom of the main fuel tank 1 is provided with a load-bearing frame, the bottom of the first auxiliary fuel tank 2 is installed on the load-bearing frame on the right side of the main fuel tank 1, and the bottom of the second auxiliary fuel tank 3 is installed on the load-bearing frame on the left side of the main fuel tank 1 . The top of the main fuel tank 1 is provided with a fuel tank wellhead 10, which is equipped with a fuel cap 8 that can cover the fuel tank wellhead 10; The secondary fuel tank 3 and the main fuel tank 1 are connected by a tee pipe 6; the tee port 9 of the tee pipe 6 is located in the oil tank wellhead 10, and is directly below the fuel cap 8, and the tee port 9 is also provided with an air outlet. A one-way valve 7 is arranged on the air hole; the three openings of the three-way pipe 6 are respectively located at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com