Rotating shaft lubricating structure of turbocharger

A turbocharger and lubricating structure technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of short service life, fast wear, poor lubrication effect, etc., to reduce loss, smooth rotation of the shaft, reduce The effect of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

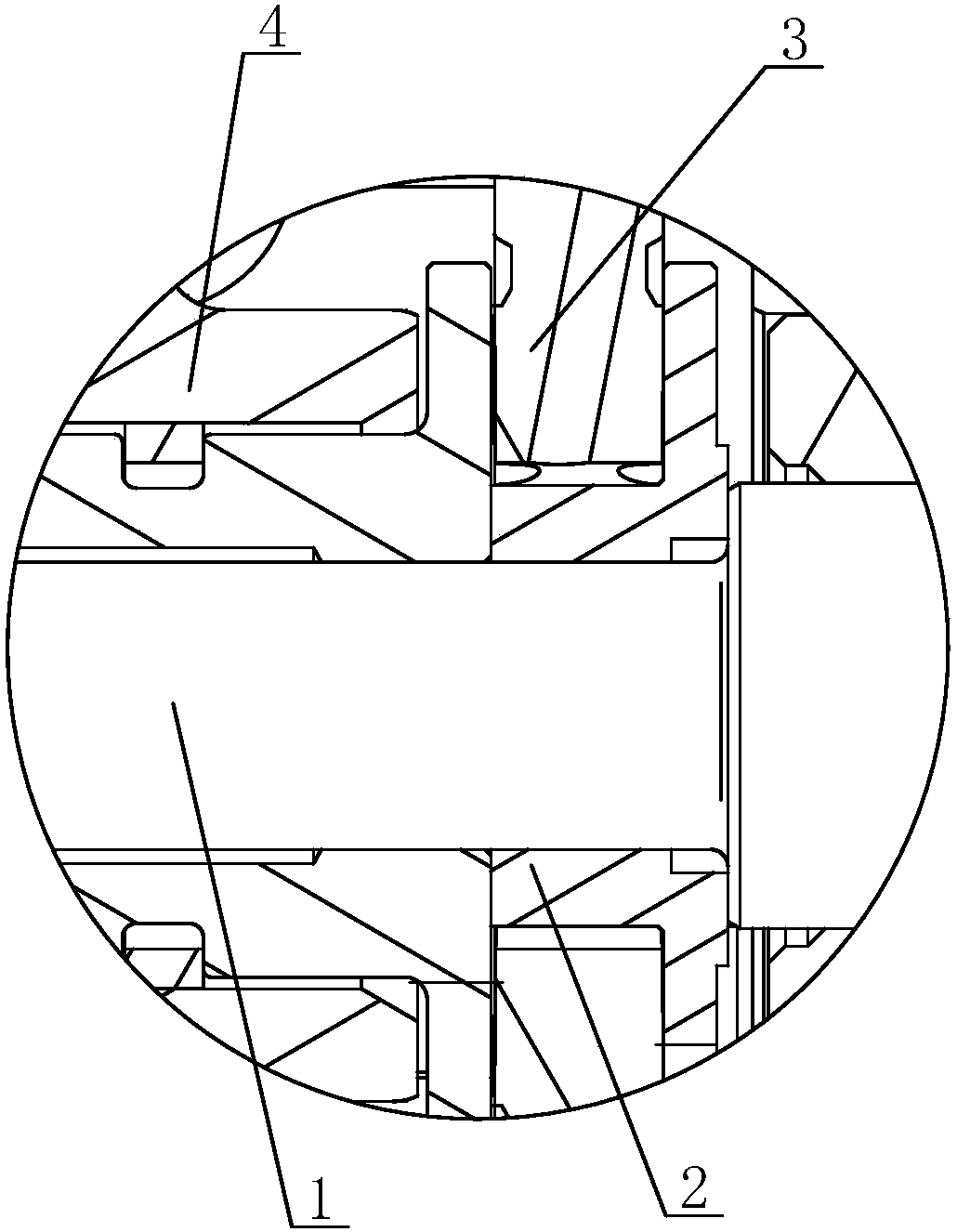

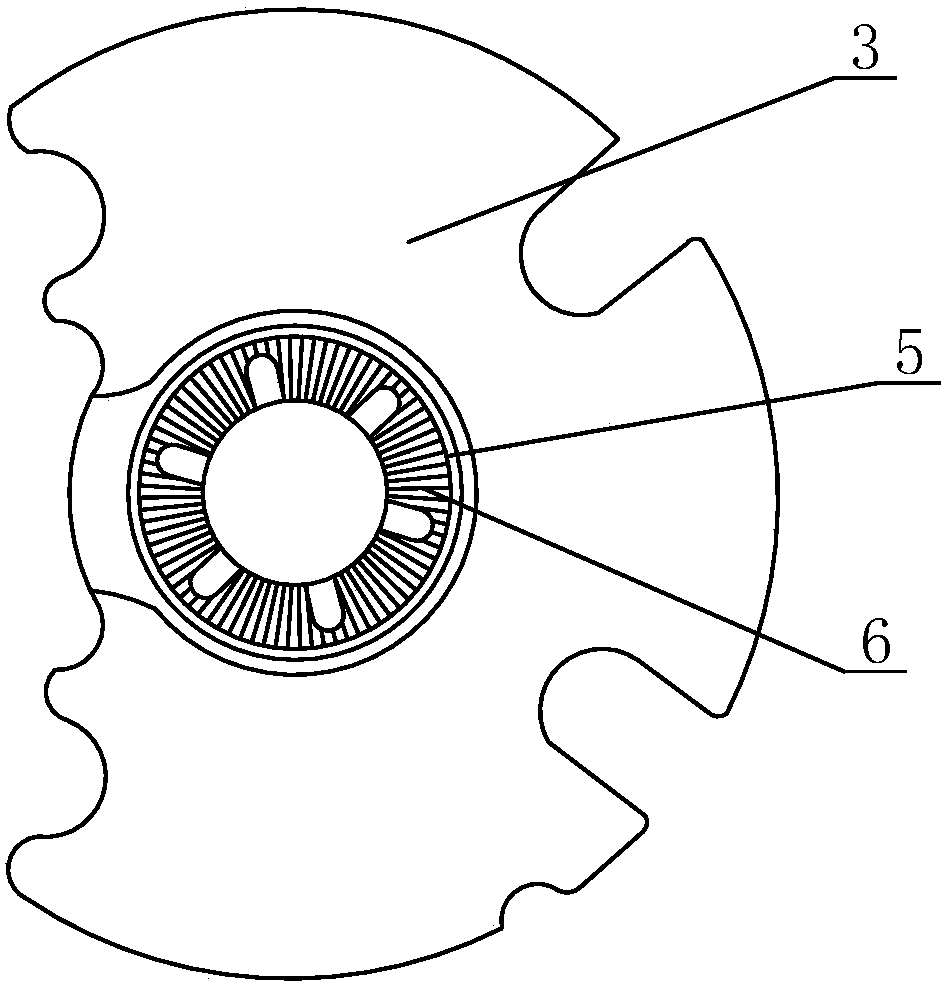

[0014] see figure 1 with figure 2 As shown, in this embodiment, a rotating shaft lubrication structure of a turbocharger includes a rotating shaft 1, a shaft seal sleeve 2 and a thrust bearing 3, and the rotating shaft 1 is arranged between the middle casing 4 of the turbocharger. Shaft seal fixed sleeve 2, the shaft seal fixed sleeve 2 is provided with a thrust bearing 3, an oil storage ring 5 is provided on the oil wedge surface of the thrust bearing 3, and several roads are arranged in the oil storage ring 5 The oil storage tank 6 , in this embodiment, the oil storage tank 6 has a straight-grained embossed structure, which is evenly distributed in the oil storage ring 5 in a radial shape.

[0015] The design of the oil storage tank 6 increases the amount of oil stored between the thrust bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com