A kind of emulsified antirust oil and preparation method thereof

A technology of anti-rust oil and formula, which is applied in the petroleum industry, lubricating compositions, etc., can solve problems such as difficult anti-rust oil accurate evaluation, and achieve the effect of excellent anti-rust and emulsifying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned emulsified antirust oil comprises the following steps in sequence: (a) adding the polymaleic anhydride in the formula amount into the naphthenic base oil in the formula amount, heating to 40-45°C, and stirring until dissolved Then stop heating; (b) continue to add the described triethanolamine of formula quantity wherein, stir 30~40 minutes; When temperature drops to room temperature, add the raw material of other formula quantity, add the deionized water of formula quantity after stirring and dissolving, then Just mix well. Mix polymaleic anhydride and naphthenic base oil evenly under heating conditions, add triethanolamine and stir for 30 to 40 minutes, and then add other ingredients, so as to ensure good compatibility of emulsified antirust oil components, and finally ensure its Antirust and emulsifying properties.

[0028] In the step (b), when the temperature drops to room temperature, add the sodium petroleum sulfonat...

Embodiment 1

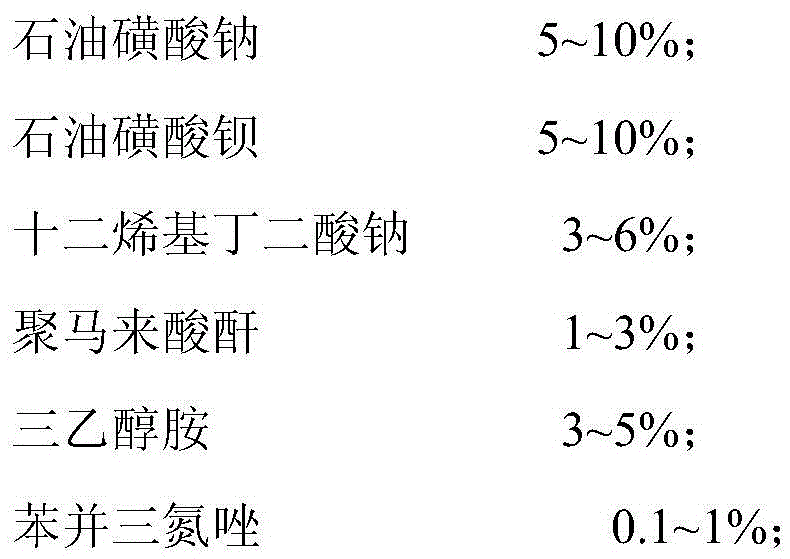

[0031] The present embodiment provides an emulsified antirust oil, which is composed of the following components by weight percentage: 5 kg of sodium petroleum sulfonate; 5 kg of barium petroleum sulfonate; 3 kg of sodium dodecenyl succinate; 1 kg of polymaleic anhydride; Triethanolamine 3kg; benzotriazole 0.1kg; C16 fatty alcohol polyoxyethylene ether carboxylic acid 2kg; isomeric C13 fatty alcohol polyoxyethylene ether 5kg; diethylene glycol monobutyl ether 1kg; 2kg; water 2kg; the balance is naphthenic base oil.

[0032] The preparation method is as follows: (a) Add 1 kg of polymaleic anhydride (molecular weight: 1000) into 70.9 kg of naphthenic base oil, heat to 40°C, stir until dissolved, and then stop heating;

[0033] (b) Continue to add 3kg of triethanolamine to it, stir for 30 minutes, and dissolve evenly; when the temperature drops to 25°C, add 5kg of sodium petroleum sulfonate, 5kg of barium petroleum sulfonate, 3kg of sodium dodecenylsuccinate, 0.1 kg benzotriazol...

Embodiment 2

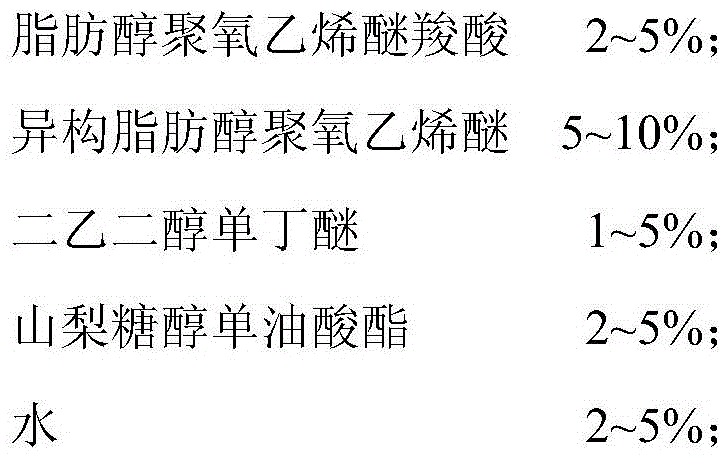

[0035] The present embodiment provides an emulsified antirust oil, which is composed of the following components by weight percentage: 10 kg of sodium petroleum sulfonate; 10 kg of barium petroleum sulfonate; 6 kg of sodium dodecenyl succinate; 3 kg of polymaleic anhydride; Triethanolamine 5kg; Benzotriazole 1kg; C18 fatty alcohol polyoxyethylene ether carboxylic acid 5kg; Isomerized C13 fatty alcohol polyoxyethylene ether 10kg; Diethylene glycol monobutyl ether 5kg; Sorbitan monooleate 5kg ; Water 5kg; The remainder is naphthenic base oil. The preparation method is consistent with that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com