Knitting and sewing all-in-one machine with variable stitch lengths

An all-in-one machine and needle gauge technology, which is applied to knitting, flat knitting machines with individual moving needles, weft knitting, etc., can solve problems such as easy missing stitches, missing stitches, and the efficiency and quality cannot meet higher requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

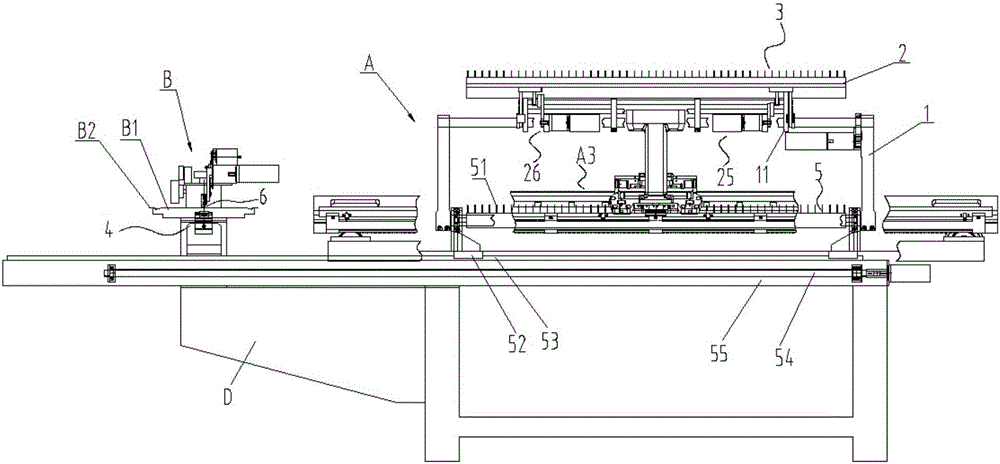

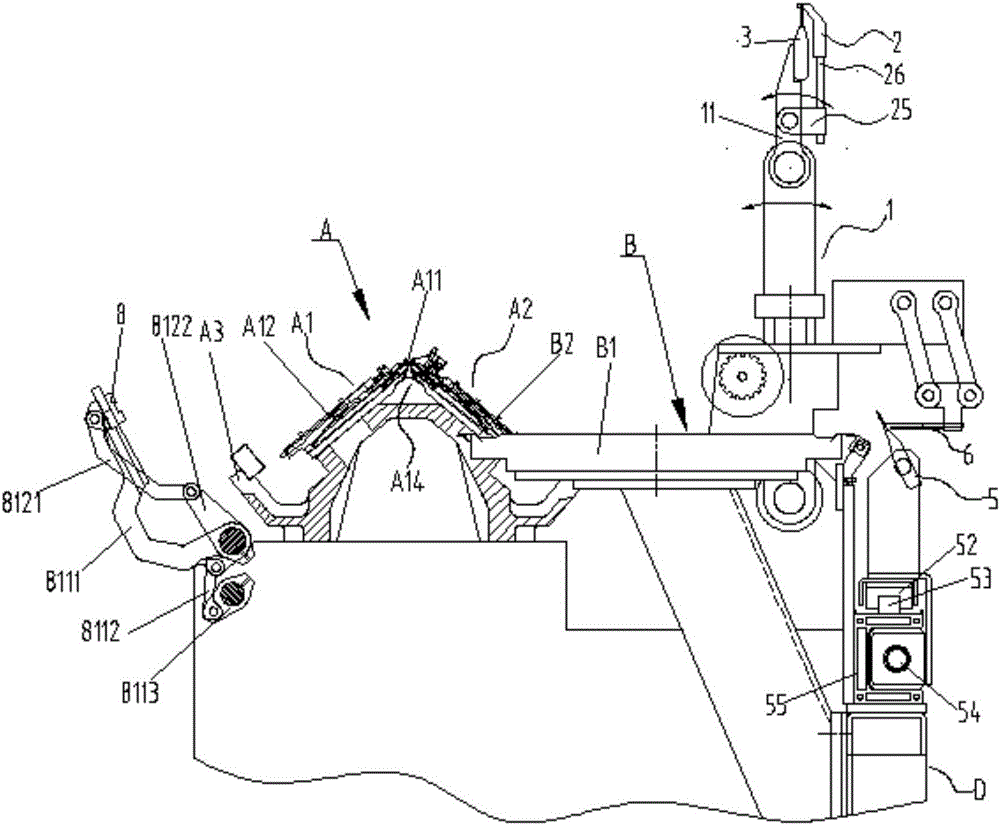

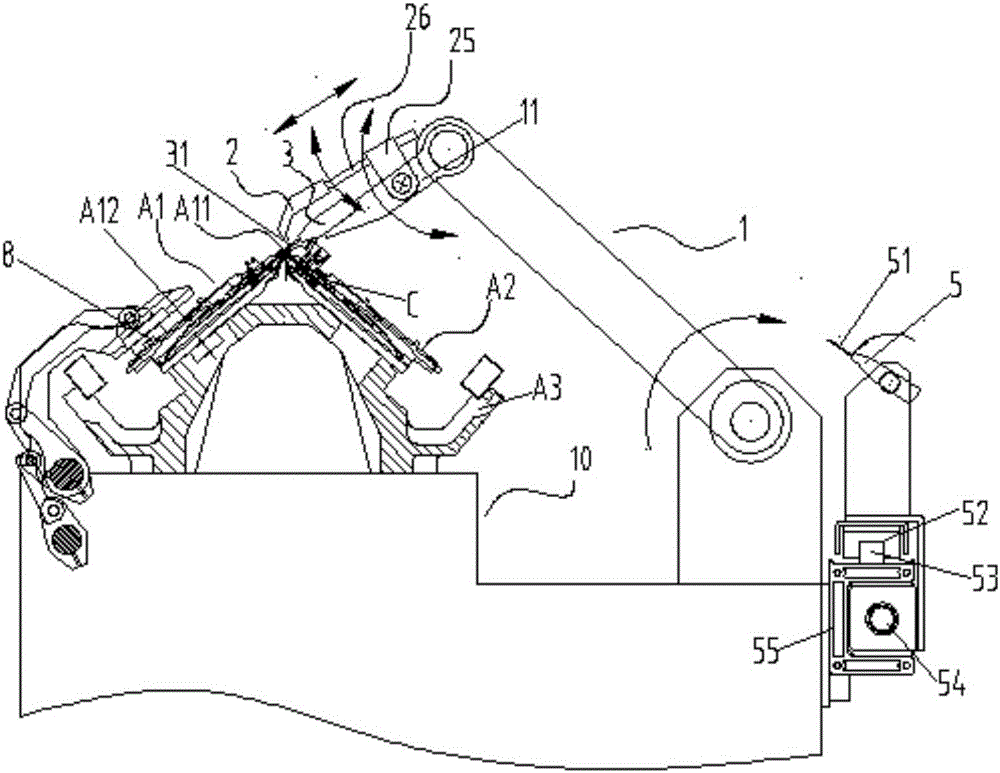

[0081] Such as figure 1 , 2 , The variable stitch knitting and sewing integrated machine of the present invention is mainly composed of flat knitting machine A, sewing machine B, sliding rail 53, sliding seat 52, needle butt push plate 8, transfer needle plate 5, large swing arm 1, female The needle plate 3, the fabric pushing rake 2, the transfer needle groove counter-connecting unit 4 and the pushing plate 6. Among them, the needle grooves of the front and rear needle plates A1 and A2 of the needle bed body A3 on the flat knitting machine A are provided with such as Picture 10 In the shown knitting needle A11 and auxiliary needle A12, the butt push plate 8 acts on the butt A121 of the auxiliary needle A12 of the knitting needle A11 in the needle groove of the front needle plate, and can also directly act on the butt of the knitting needle ( Not shown) to drive the knitting needle A11 to move in the needle groove. The sewing machine B is placed on the right side of the flat k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com