Preparation method and application of efficient flame retardation after-finishing agent

A post-finishing and flame retardant technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of non-flame retardant properties, polyester safety hazards, burns, etc., to ensure softness and feel, increase flame retardant effect, good hygroscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

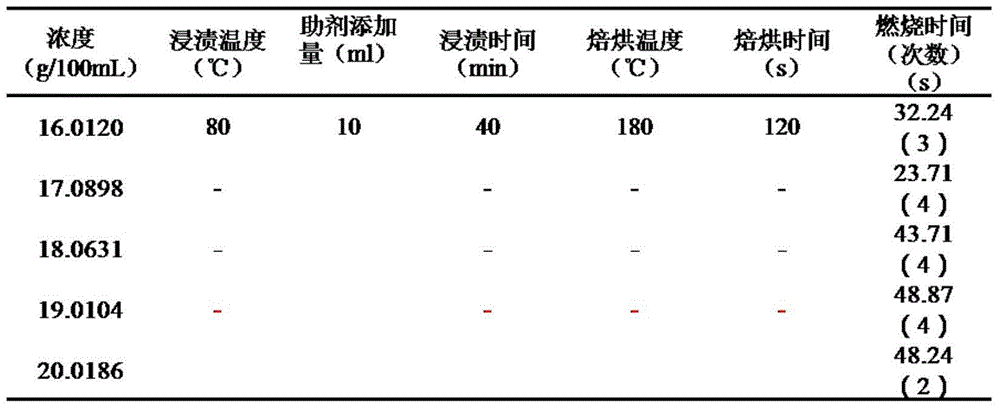

[0021] The sample size is 1.5cm wide and 15cm long PET warp-knitted short fleece fabric. The reason why the short fleece fabric is selected is that the fleece fabric has a larger specific surface area and is more flammable than other fabrics. The experimental data of the relationship between ATP concentration, burning time and burning times are shown in the table below:

[0022] Table 1 ATP concentration and burning time and burning times

[0023]

[0024] The number of burning times in the table is the number of times the fabric after flame-retardant finishing is automatically extinguished during the burning process, indicating that the PET fabric after ATP finishing has the characteristics of self-extinguishing. time.

Embodiment 2

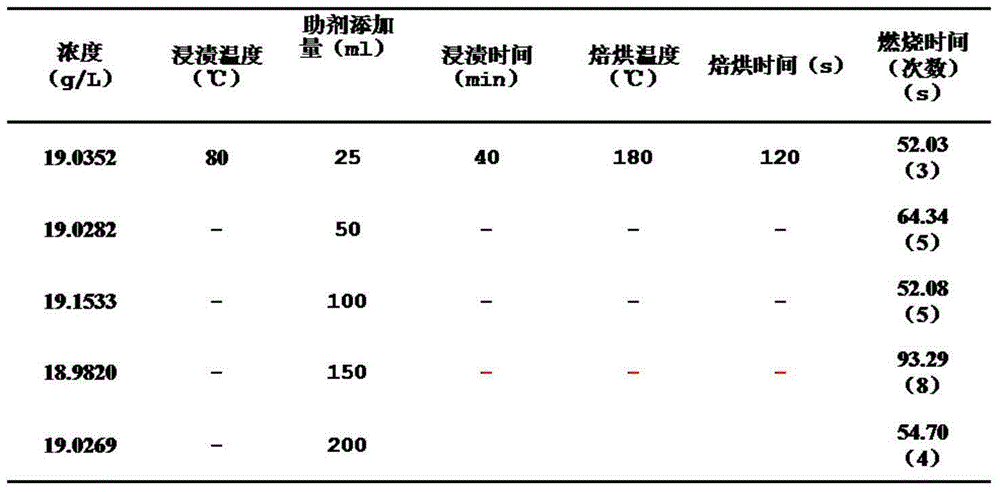

[0026] The relationship between glycerol concentration and burning times and time is shown in the table below:

[0027] Table 2 Glycerol concentration and burning time and burning times

[0028]

[0029] It can be seen from the table that when the auxiliary agent glycerin is added to 150ml / L, the flame retardant effect is the best. During the combustion test, the number of self-extinguishing times reached 8 times, and the burning time reached 93.29 seconds.

Embodiment 3

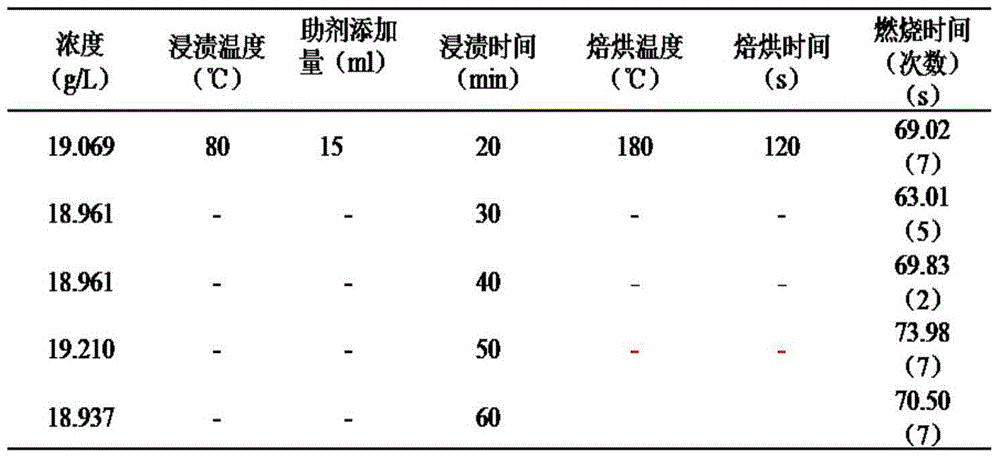

[0031] The experimental data of the relationship between immersion time, burning time and burning times are shown in the table below

[0032] Table 3 Immersion time and burning time and burning times

[0033]

[0034] From the data in Table 3, draw a line chart of the relationship between the immersion time, the burning time and the number of burning times, and it can be concluded that the best process should choose the immersion time to be 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com