Manufacturing process for efficient waterproof inflaming-retarding polyester fabric

A flame retardant polyester and production technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of loss of flame retardant function, shorten the use time of fabrics, etc., to increase the flame retardant effect, ensure softness and feel, and good moisture absorption. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

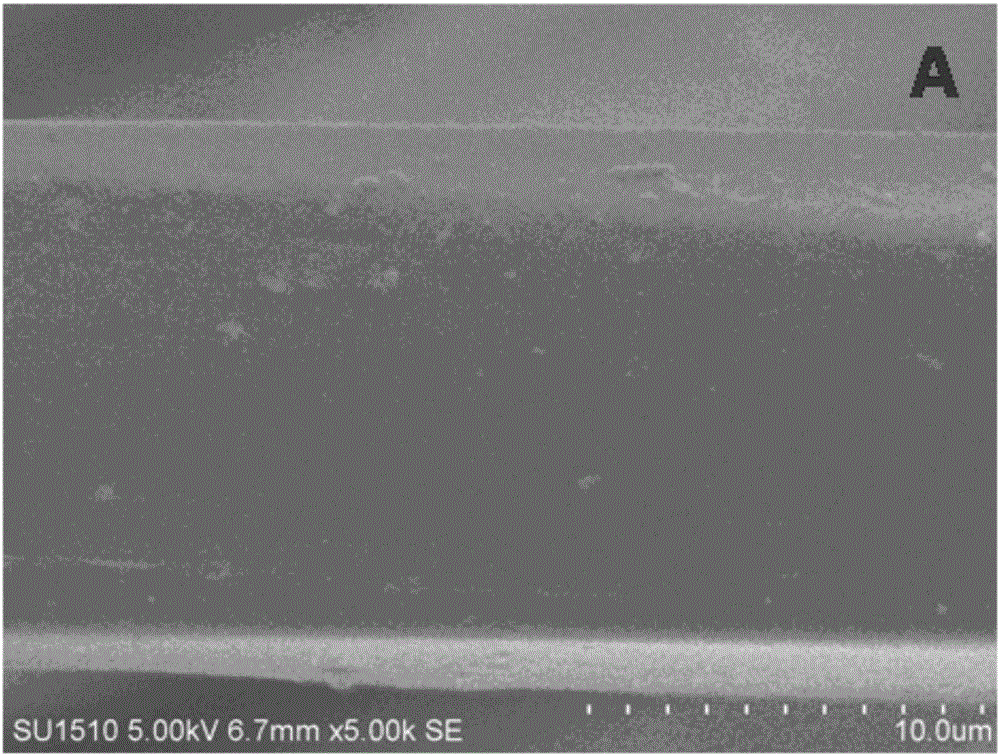

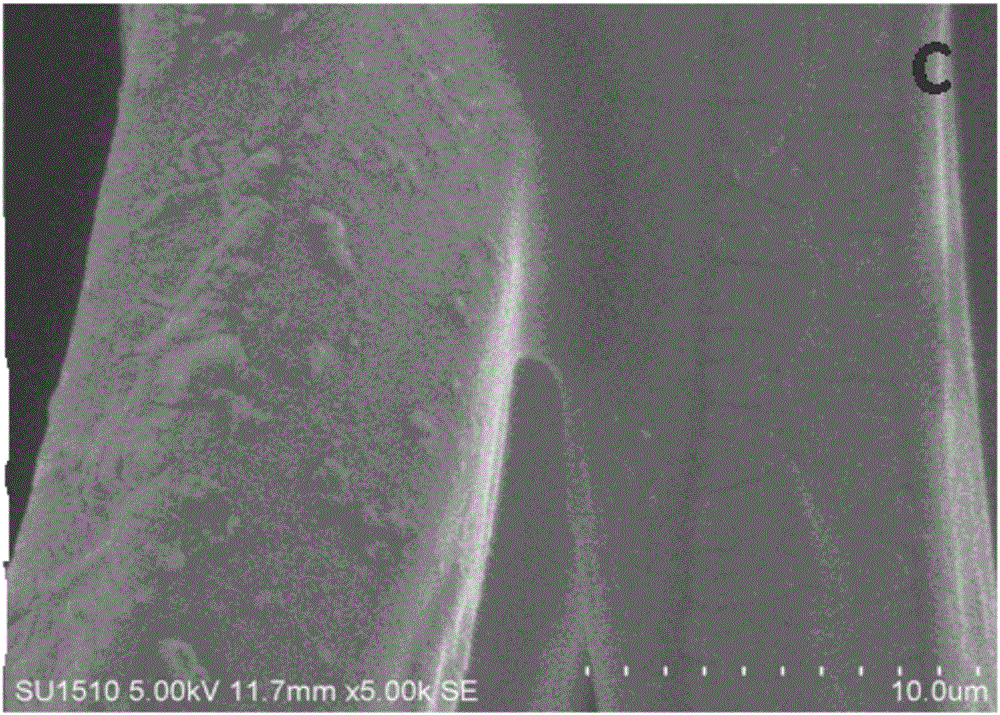

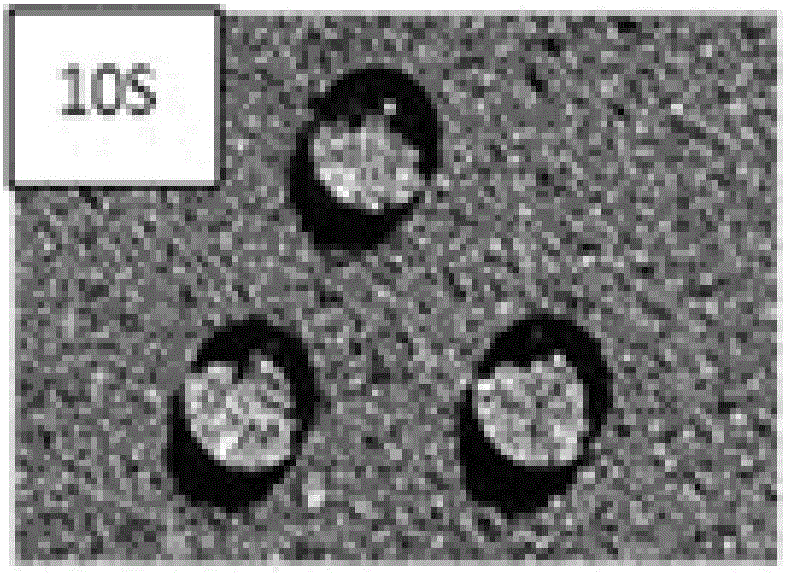

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of manufacturing process of high-efficiency waterproof flame-retardant polyester fabric, comprises the following steps:

[0024] (1) Add flame retardant MCA to ethanol, heat to 40°C and fully stir for 2 hours at a stirring speed of 200 rpm to obtain solution A; add solution A to water and stir fully at 20°C for 1.5 hours at a stirring speed of Be 200 rev / mins, obtain solution B; The content of flame retardant MCA is 50g / L in the described solution A, and the content of flame retardant MCA in solution B is 10g / L;

[0025] (2) Use solution C to adjust the pH value of solution B to 6 to obtain solution D; said solution C is obtained by dissolving 0.0005 gram of NaOH in 10 ml of distilled water;

[0026] (3) stir after adding glycerol and tannic acid in solution D, obtain finishing agent; The content of glycerol is 10ml / L in the described finishing agent, and the content of tannic acid is 5g / L;

[0027] (4) Fabric pre-treatment: Soak the polyester fabr...

Embodiment 2

[0030] Embodiment 2: A kind of manufacturing process of high-efficiency waterproof flame-retardant polyester fabric, comprises the following steps:

[0031] (1) Add flame retardant MCA to ethanol, heat to 60°C and fully stir for 0.5 hours at a stirring speed of 600 rpm to obtain solution A; add solution A to water and stir at 25°C for 0.5 hours at a stirring speed of Be 600 rev / mins, obtain solution B; The content of flame retardant MCA is 200g / L in the solution A, and the content of flame retardant MCA is 50g / L in the solution B;

[0032] (2) Use solution C to adjust the pH value of solution B to 6.5 to obtain solution D; said solution C is obtained by dissolving 0.0015 grams of NaOH in 10 ml of distilled water;

[0033] (3) stir after adding glycerol and tannic acid in solution D, obtain finishing agent; The content of glycerol is 60ml / L in the described finishing agent, and the content of tannic acid is 50g / L;

[0034] (4) Fabric pretreatment: Soak the polyester fabric in ...

Embodiment 3

[0037] Embodiment 3: A kind of manufacturing process of high-efficiency waterproof flame-retardant polyester fabric, comprises the following steps:

[0038] (1) Add flame retardant MCA to ethanol, heat to 50°C and fully stir for 1 hour at a stirring speed of 500 rpm to obtain solution A; add solution A to water and stir at 24°C for 1 hour at a stirring speed of Be 500 rev / mins, obtain solution B; The content of flame retardant MCA is 100g / L in the solution A, and the content of flame retardant MCA in solution B is 20g / L;

[0039] (2) Use solution C to adjust the pH value of solution B to 6 to obtain solution D; said solution C is obtained by dissolving 0.001 gram of NaOH in 10 ml of distilled water;

[0040] (3) stir after adding glycerol and tannic acid in solution D, obtain finishing agent; The content of glycerol is 30ml / L in the described finishing agent, and the content of tannic acid is 10g / L;

[0041] (4) Fabric pretreatment: Soak the polyester fabric in 10g / L NaOH sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com