Internal pressing plate of energy-saving curtain wall

A technology for internal pressure panels and curtain walls, applied to walls, building components, buildings, etc., can solve the problems of inconvenient installation of decorative lines on curtain walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

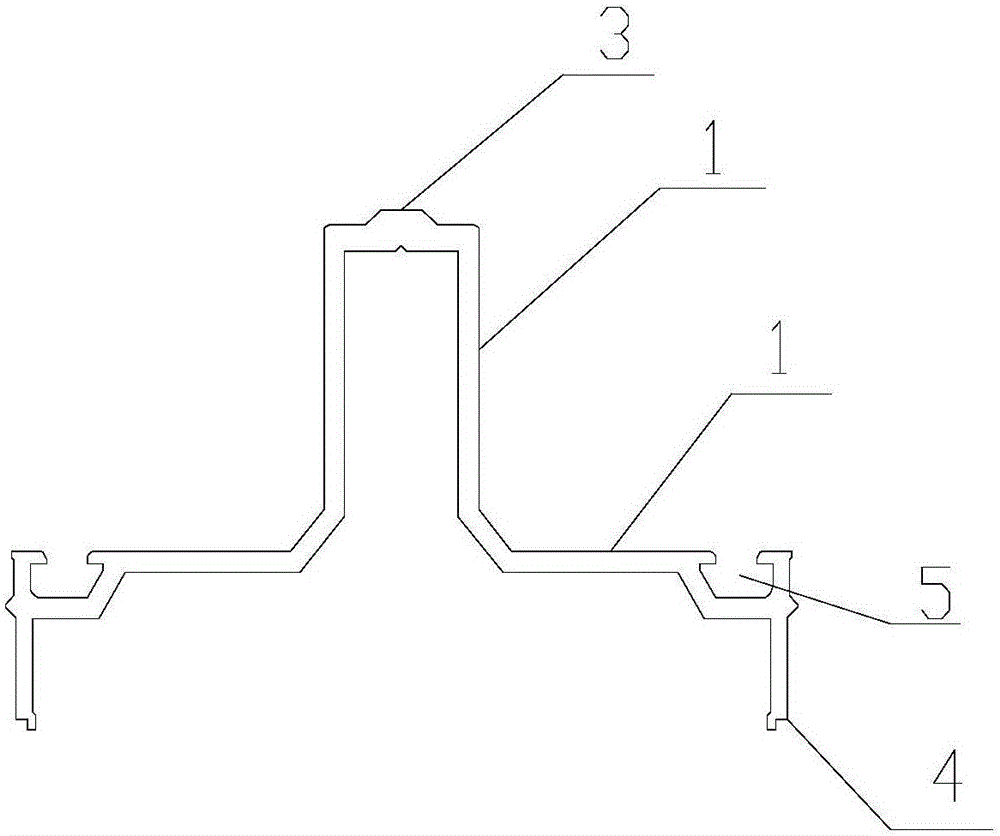

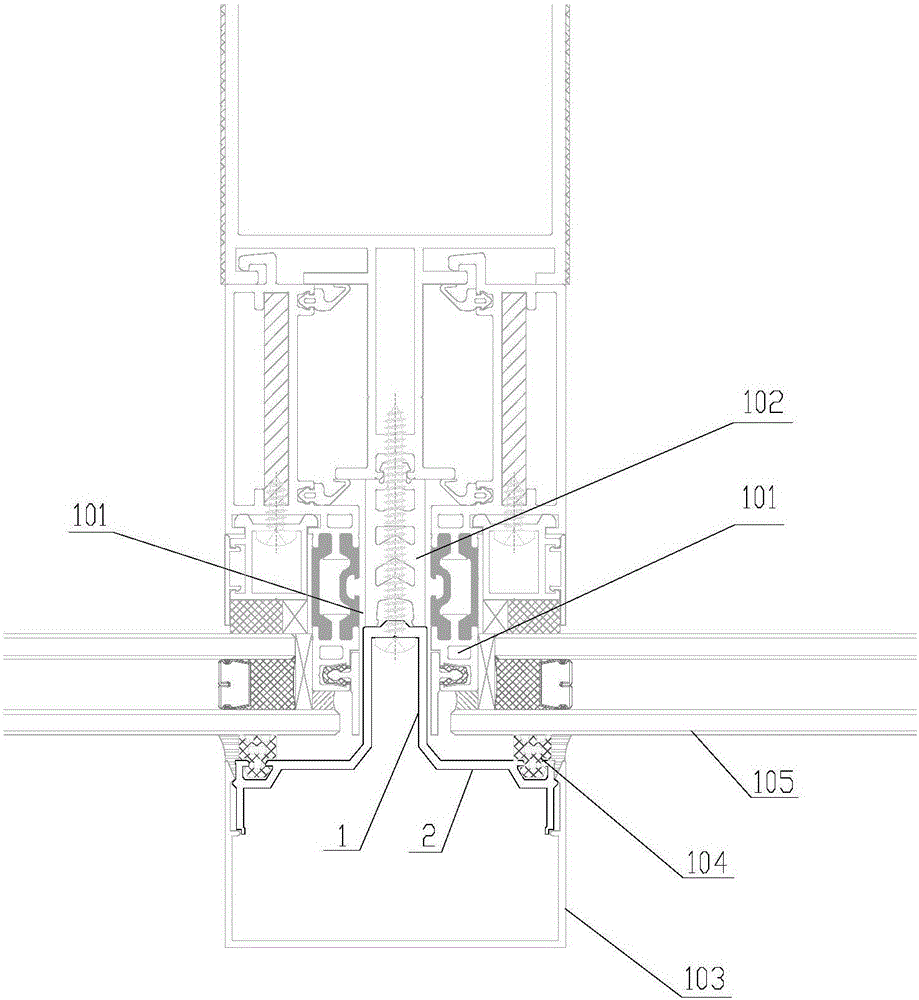

[0010] like Figure 1 to Figure 2 The shown inner pressure plate of the energy-saving curtain wall includes: a boss 1 and a base 2, and the width of the boss 1 is the same as the gap between the glass frames 101, so that the gap is filled. A protrusion 3 is provided at the end of the boss 1 for riveting with the heat-insulating rubber strip 102 ; a notch 4 is provided on the bottom surface of the base 2 for connecting with the decorative line 103 .

[0011] In order to prevent water from flowing into the interior of the curtain wall from the glass plate and the inner pressure plate, the top surface of the base 2 is provided with a groove 5 for fixing the rubber strip 104 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com