A drainage type insertion device in a heat exchange tube

A technology for inserting devices and heat exchange tubes, which is applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc. It can solve the problems of enhanced heat transfer comprehensive performance limitations, difficult processing, support, and application range limitations, etc., to achieve The effect of small flow resistance, improved heat transfer, and reduced disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

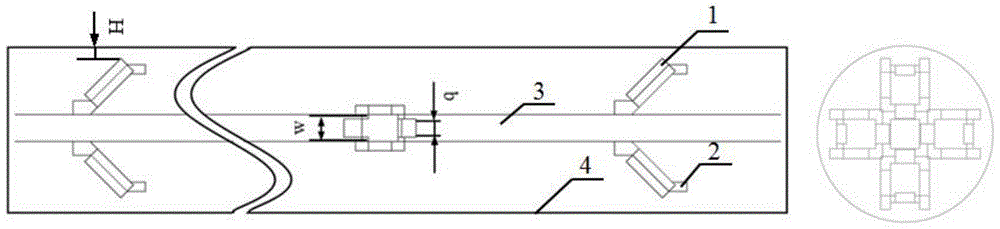

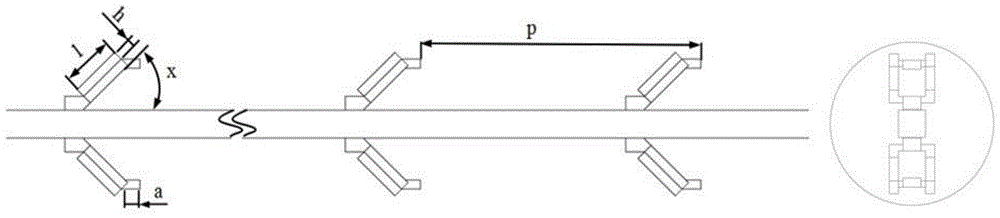

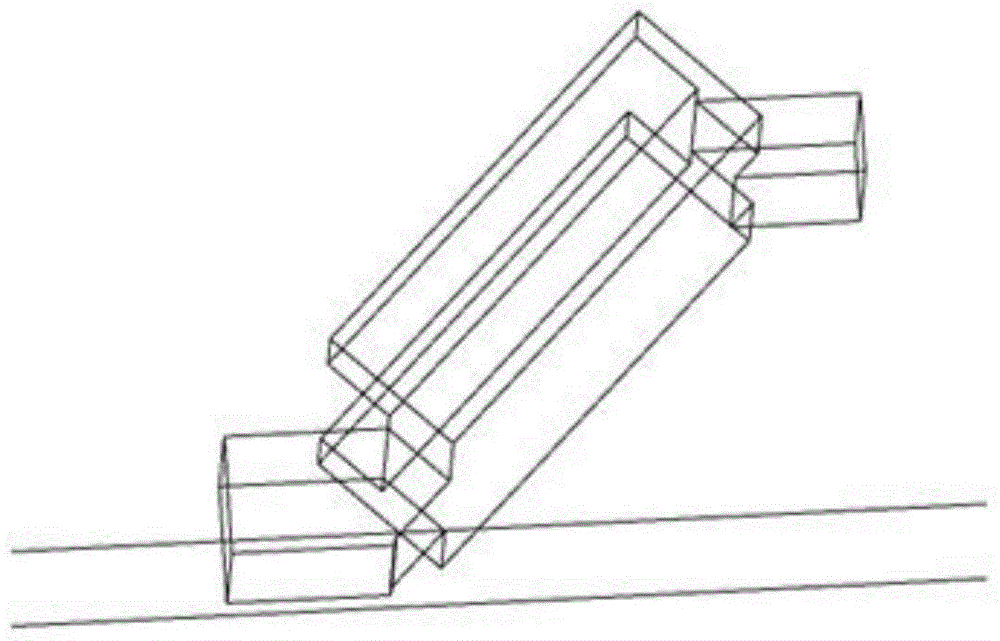

[0032] In this embodiment, a round tube with an inner diameter of 18 mm and a length of 500 mm is used, and the boundary conditions for fully developed inlet velocity and inlet temperature are given at the inlet, and 2000 W / m is given for the wall surface 2 The condition of constant heat flow, the outlet is free flow, the surface of the insertion device is insulated, and the distance between the horizontal flow channel and the pipe wall is 2mm. Using the insertion device model shown in Figure 1, every two insert units are symmetrically arranged on both sides of the support rod 3 to form a group of turbulence units, and the pitch between each two groups of turbulence units is p=30mm , according to the arrangement pitch and the length of the heat exchange tubes, there are altogether 12 sets of turbulence units, and a total of 24 insert units. The actual needs are selected and limited. The increase in the number of turbulence units arranged will improve the heat exchange capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com