Testing tool and testing method for rigidity of clamp movable positioning mechanism

A detection tool and active positioning technology, applied in the direction of applying stable tension/pressure to test material strength, measuring device, strength characteristics, etc. problem, to achieve the effect of simple structure, improved detection efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

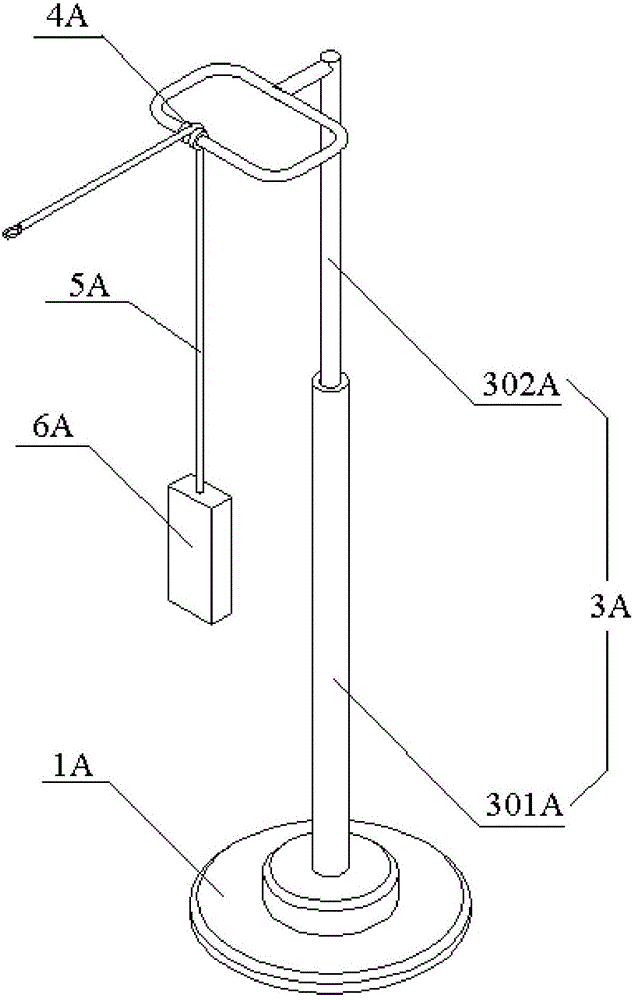

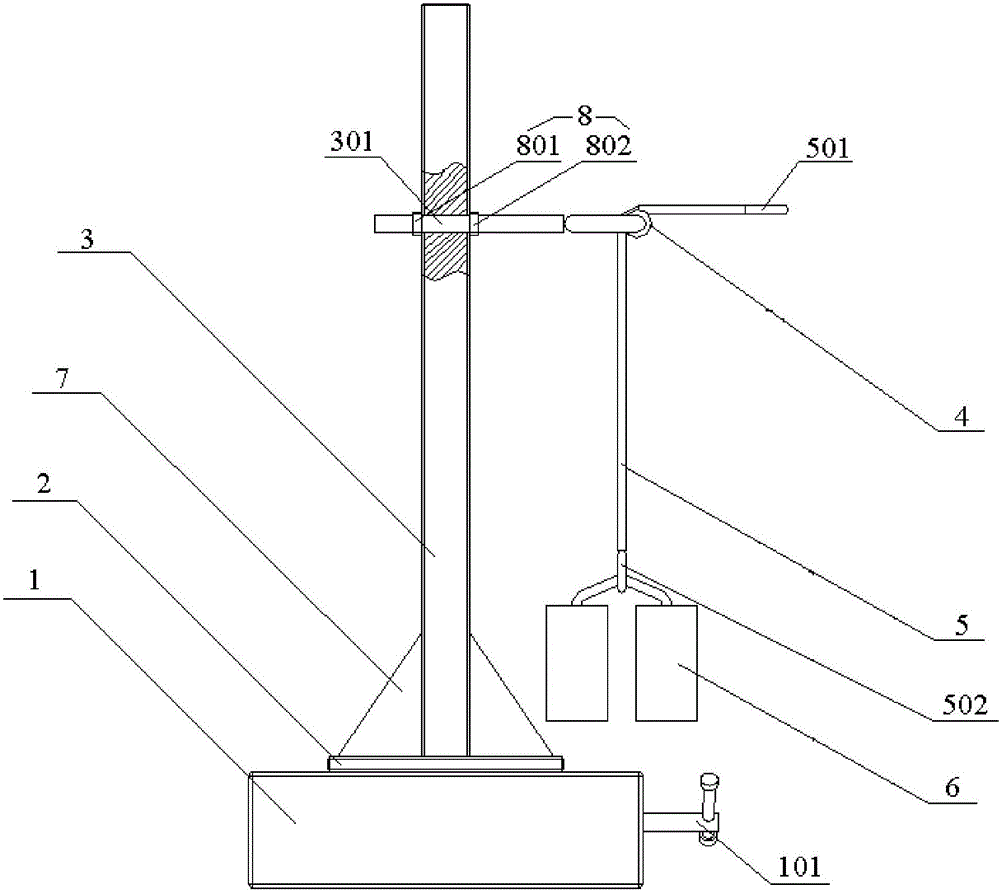

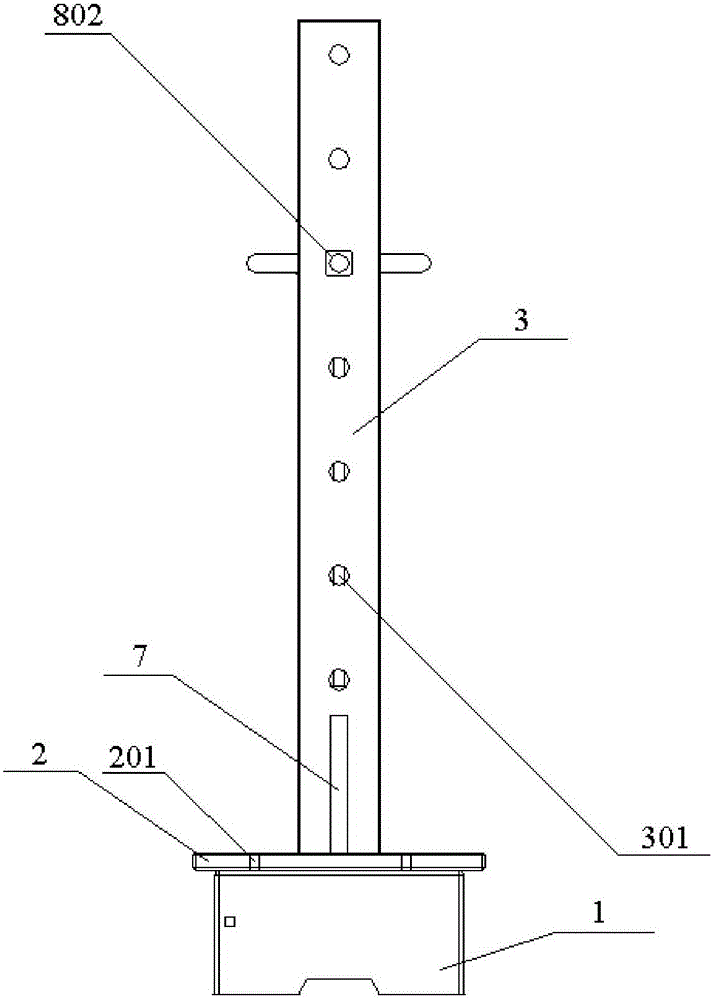

[0050] The first aspect of the present invention provides a tool for detecting the rigidity of the clamp movable positioning mechanism, see figure 2 and combine image 3 , the detection tools include:

[0051] Magnetic base 1, support plate 2, support rod 3, pulley mechanism 4, traction member 5 and counterweight 6; the magnetic base 1, support plate 2 and support 3 rods are connected in sequence; The height direction is provided with a plurality of pulley mechanism positioning structures 301, and the pulley mechanism 4 is fixed on the support rod 3 through the pulley mechanism positioning structure 301; the traction member 5 passes through the pulley mechanism 4, and the The first end of the traction component 5 is connected to the counterweight 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com