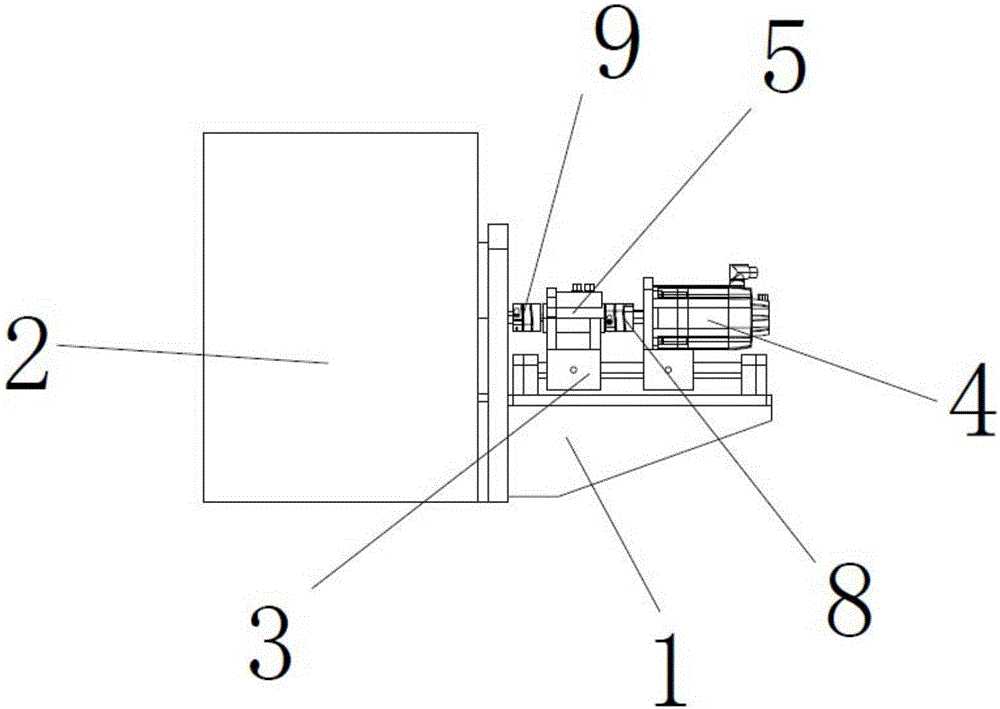

Test bench for testing working conditions of motor under different temperature environments

A technology of temperature environment and test environment, which is applied in the direction of motor generator testing, measuring device casing, etc., can solve the problem that the detection means cannot perfectly test the state of brushless motors, etc., and achieve fast detection speed, simple structure, and improved sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

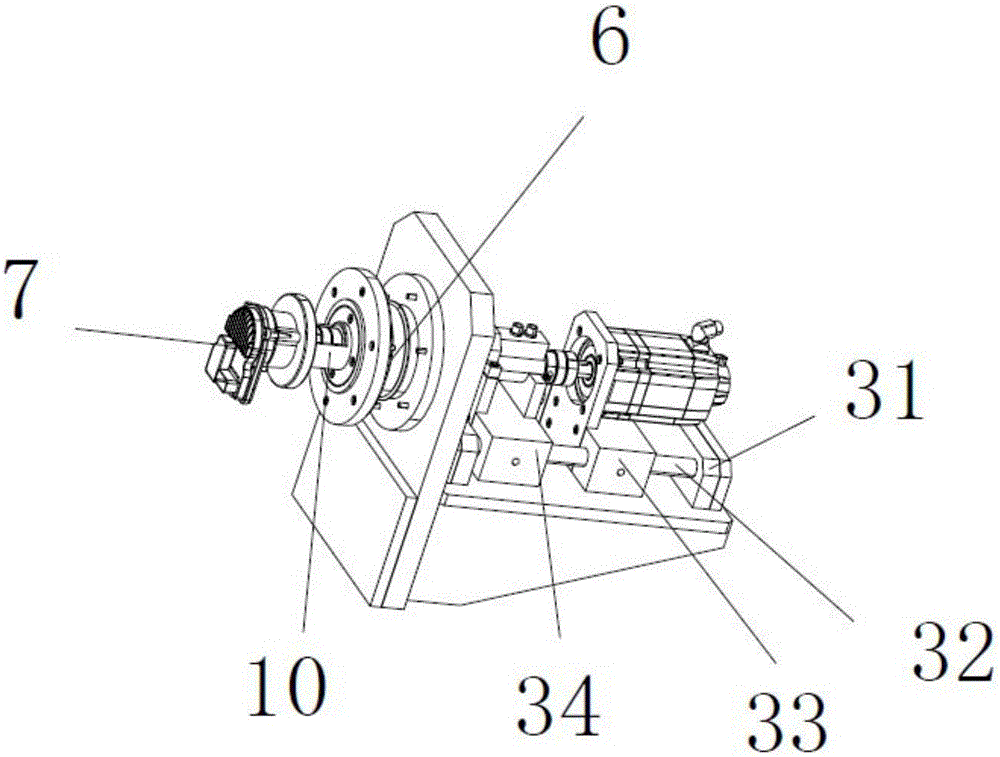

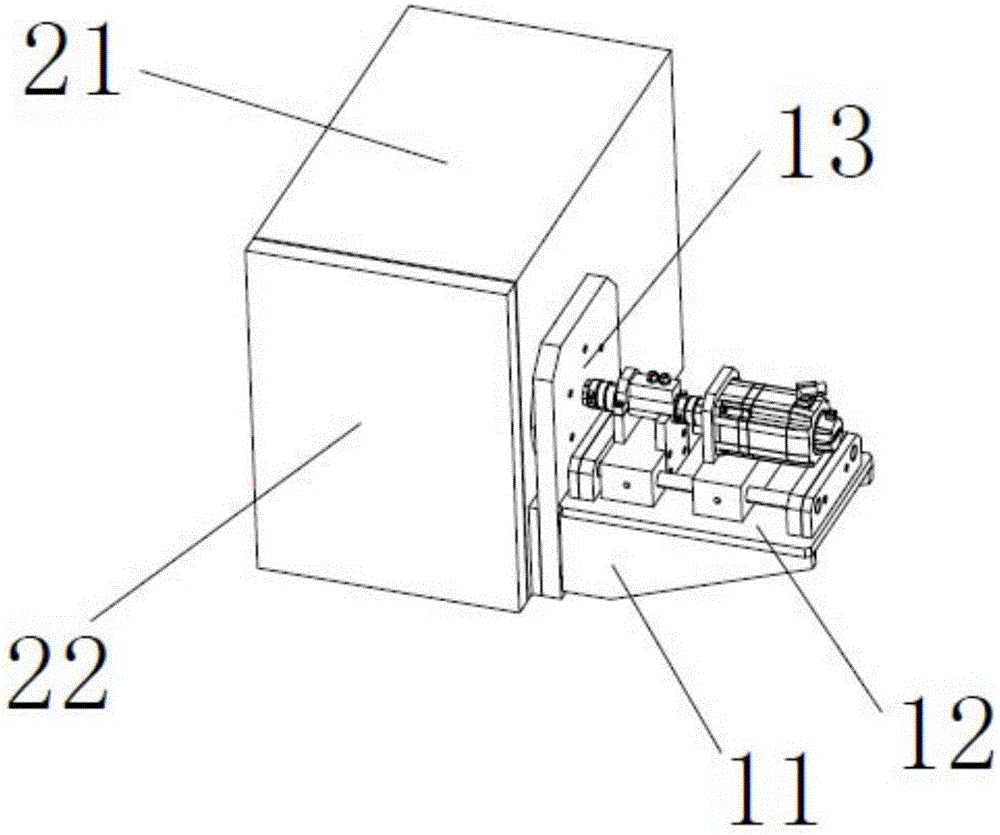

Embodiment 1

[0027] When it is necessary to use the device to test the brushless motor, first open the lid 22 of the test environment control box 2, and then connect the main shaft of the test motor 7 to the main shaft of the sealing box sealing assembly 6 through the third coupling 10, Rotate the sealing box closing assembly 6, so that the sealing box closing assembly 6 is close to the inner wall of the test environment control box 2, improve the sealing performance of the entire test environment control box 2, then close the box cover 22, and simultaneously control the test environment through the test environment control box 2 The internal temperature of the box 2, when the temperature reaches the test temperature, start the servo motor 4, the main shaft of the test environment control box 2 drives the main shaft of the test motor 7 to rotate, while the test motor 7 rotates, the torque sensor 5 will collect the motion state of the test motor 7, The data is transmitted to the computer thr...

Embodiment 2

[0030] When the whole test bench needs to be maintained, at first open the case cover 22 of the test environment control box 2, the third shaft coupling 10 and the sealing box sealing assembly 6 are disassembled, and then the fixed bench 1 is removed from the test environment control box 2 side The wall is disassembled, and then the mounting table 3 is disassembled from the fixed table 1, and the worker can carry out the test environment control box 2, the mounting table 3, the fixed table 1, and the torque sensor 5 and the servo motor 4 on the mounting table 3. For detection and maintenance, when the torque sensor 5 or the servo motor 4 needs to be replaced, first remove the first coupling 8, so that the servo motor 4 and the torque sensor 5 are separated, and then put the servo motor 4 and the torque sensor 5 on the installation platform 3 The two ends are translated to make it easy to replace the servo motor 4 and the torque sensor 5, and then replace the servo motor 4 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com