Terminal front cover assembly and mobile terminal

A technology of front cover components and terminals, which is applied in the direction of casing/cabinet/drawer components, sealed casings, etc., which can solve the problems of increasing the thickness, loss, and inability to achieve dustproof and waterproof effects of intelligent terminal products, so as to ensure the overall Appearance decoration effect, effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

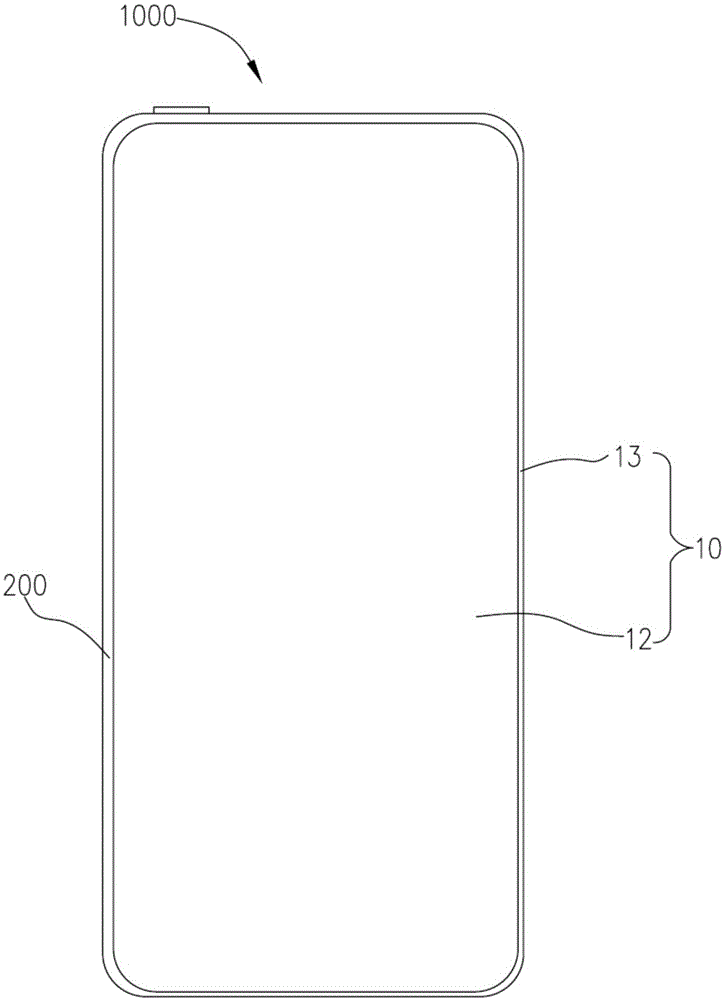

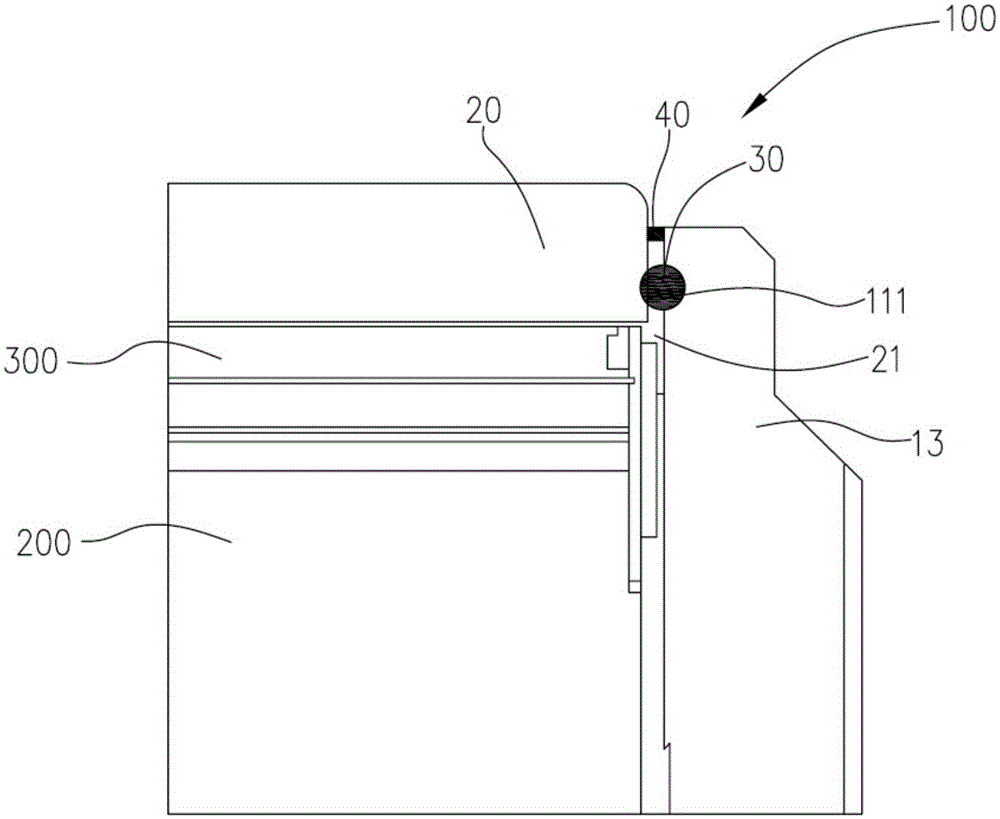

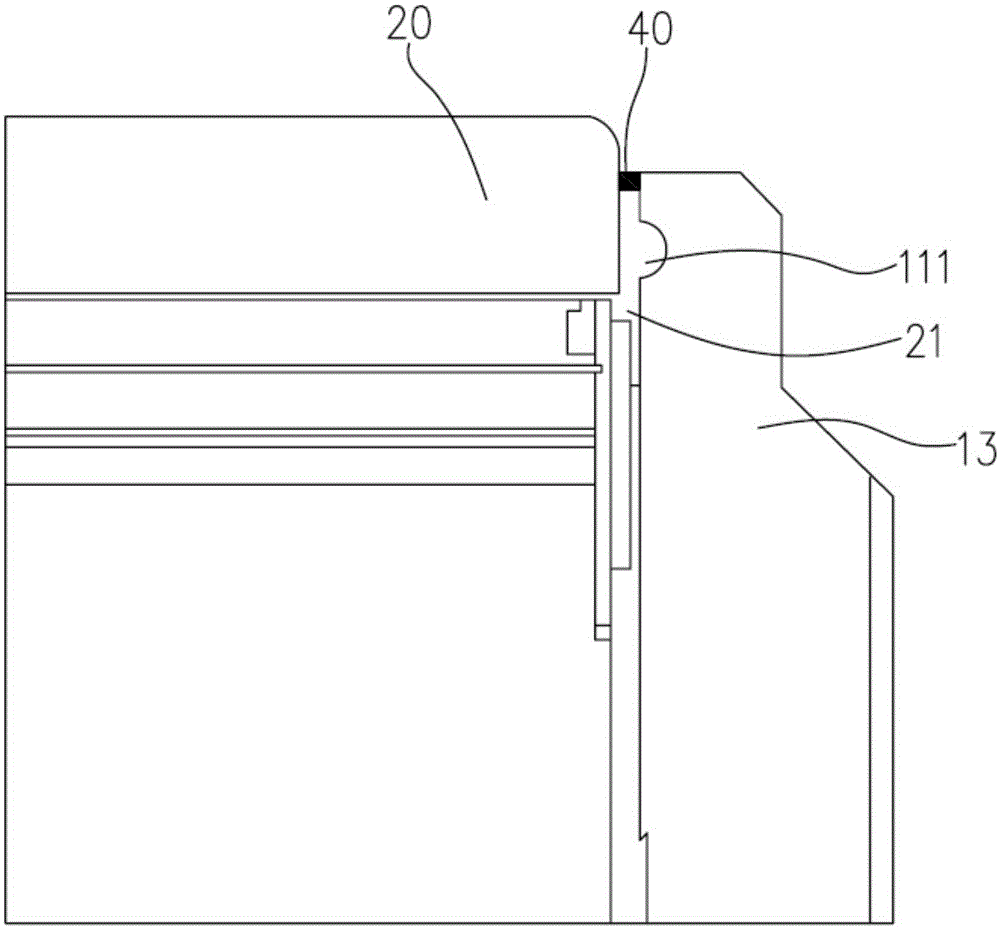

[0022] Please also refer to Figure 1 to Figure 3 , the present invention provides a terminal 1000, the terminal 1000 includes a terminal front cover assembly 100, a body 200, a control assembly (not marked in the figure) and a display screen 300, the terminal front cover assembly 100, the control assembly and the display The screens 300 are all connected to the body. The control assembly is used to control the display screen 300 to display image information, and the terminal front cover assembly 100 is fixedly connected to the display screen 300 . The terminal 1000 may be a mobile phone, a notebook computer, a tablet computer, an electronic reader, an electronic photo album, a display, and the like. In this embodiment, description is made by taking the terminal 1000 as a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com