Method for machining toothed workpieces, machining unit therefor and machine tool equipped with such a machining unit

A technology for processing units and workpieces, applied to components with teeth, metal processing equipment, gear cutting machines, etc., can solve problems such as gear tooth damage, and achieve the effect of wide tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

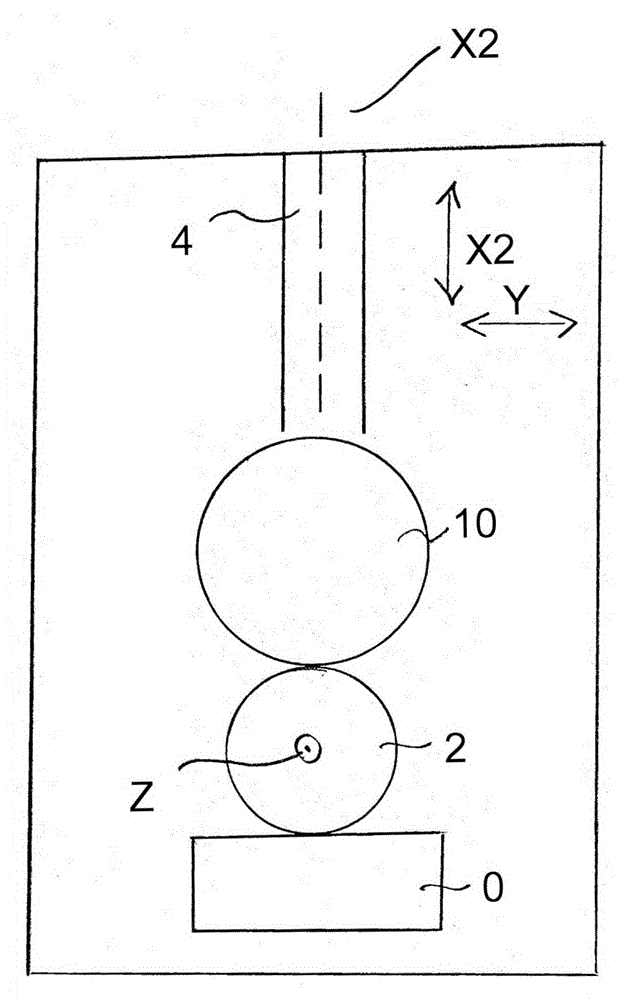

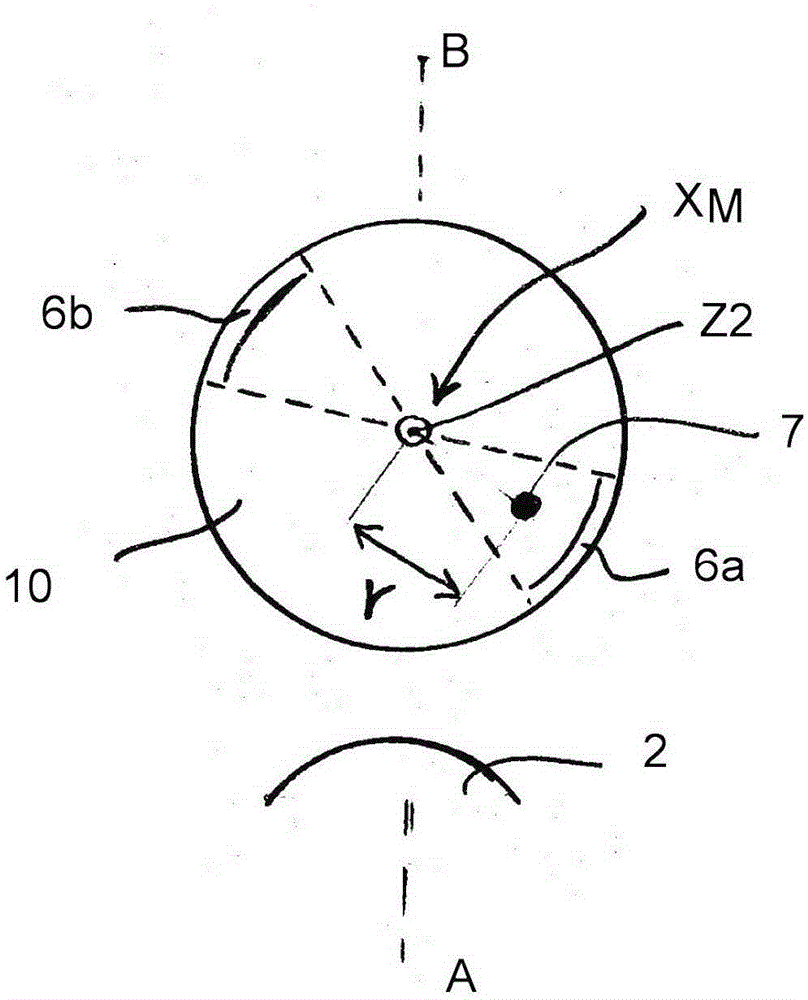

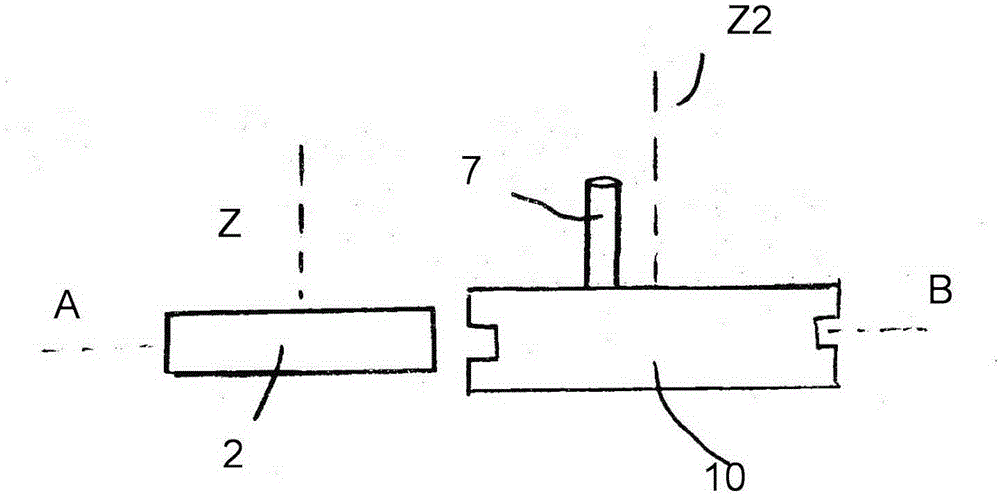

[0035] In the simplified schematic diagram from above, figure 1 Selected portions of machine tool 20 are shown, which are sufficient for an understanding of the invention. In this embodiment, the machine tool 20 is a hobbing machine, the main design of which is known and will not be further explained herein. exist figure 1 Shown in are all hob milling tools (hob 0) whose mobility is defined by the conventional axes of motion required for the machining of gear teeth on blanks mounted in the production of toothed workpieces 2 on the workpiece mandrel. exist figure 1 In what is shown, the workpiece axis Z is oriented orthogonally to the plane of the drawing.

[0036]In this example, the chamfering tool 10 , which can perform a transverse movement along the axis of movement X2 , is arranged on the side of the workpiece 2 diametrically opposite the hob 0 . However, the axis of movement X2 of the chamfering tool can also be oriented at an angle to the axis of the main tool, eg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com