electropneumatic valve group

A valve group, electric technology, applied in the direction of fluid pressure actuation system components, valve devices, valve details, etc., can solve the problems of long switching time, complex manufacturing technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

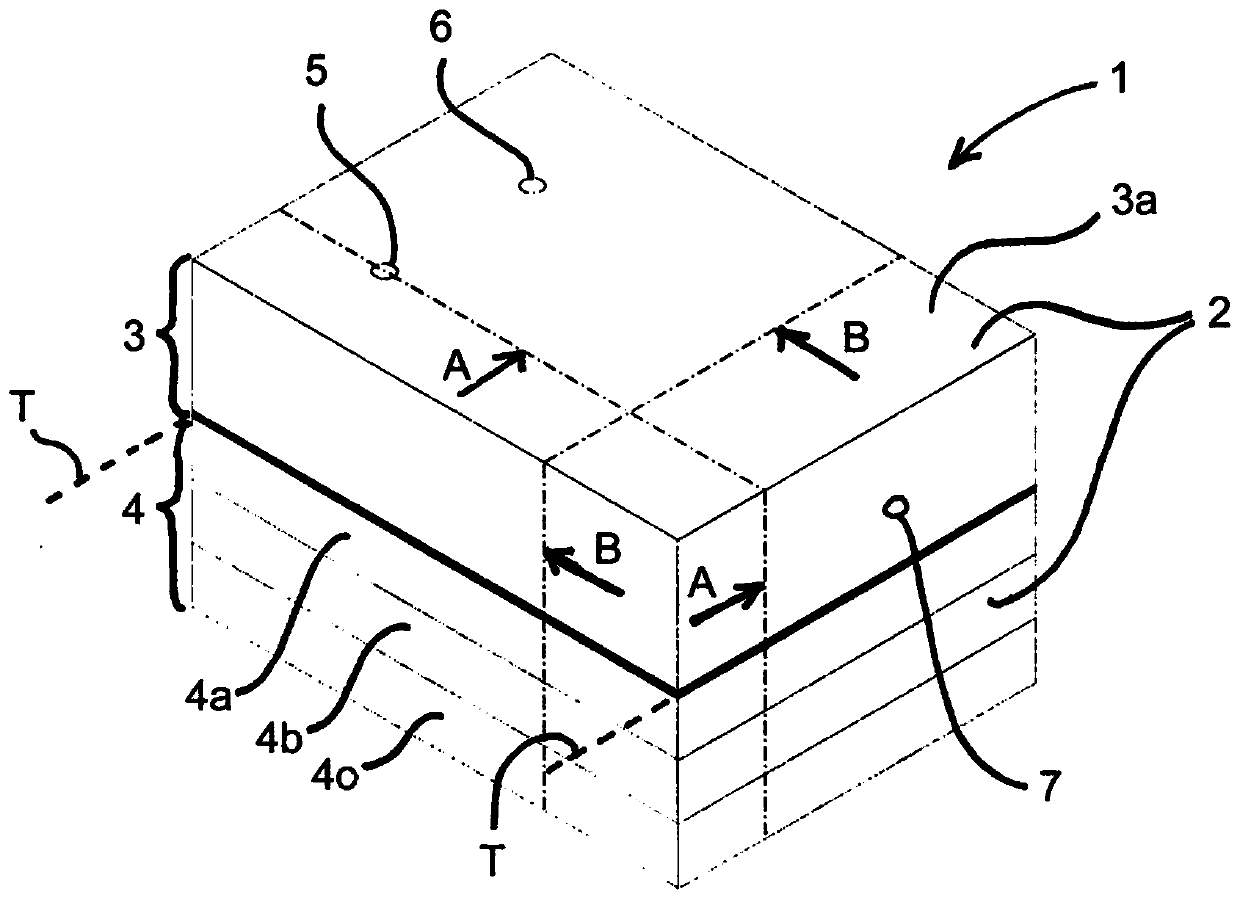

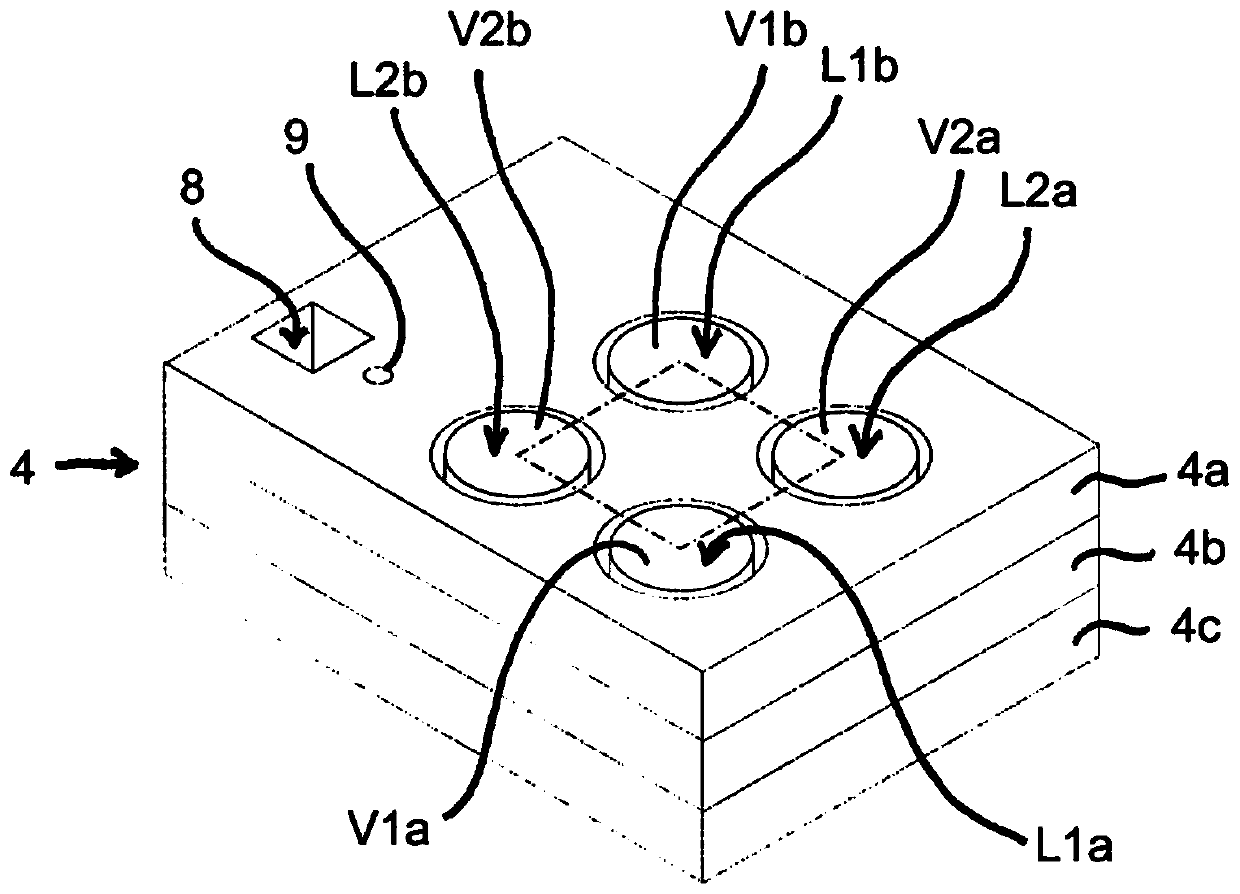

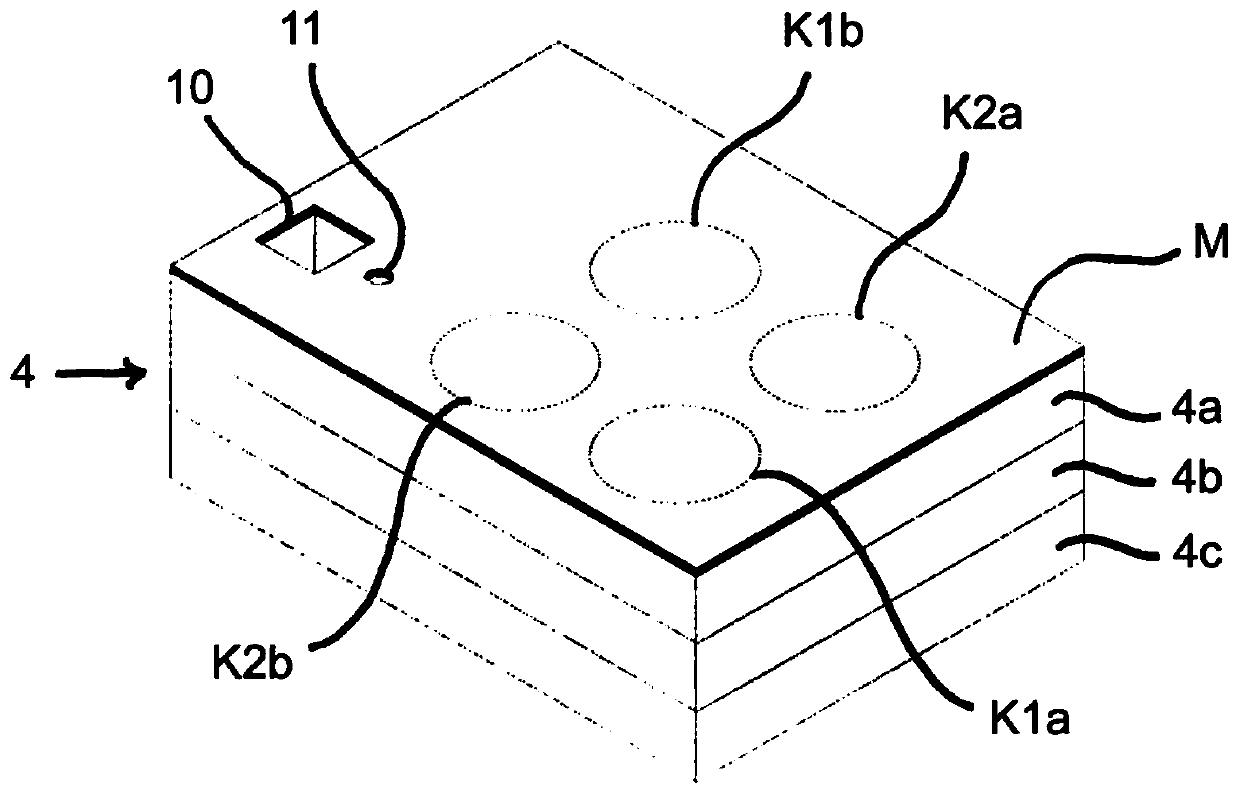

[0043] Figure 1-8 Various (partial) views and cutouts are shown of an exemplary embodiment of an electropneumatic valve group 1 according to the invention, which comprises a total of two pilot valves P1, P2 and four power valves L1a, L1b, L2a, L2b. In this case, the pilot valve P1 is used for actuating and switching the first pair of power valves L1a, L1b, and the pilot valve P2 is used for actuating and switching the second pair of power valves L2a, L2b, as will be explained further below.

[0044] in accordance with figure 1 Perspective view of housing 2 of an embodiment of valve bank 1 and according to Figure 7 and 8 (in accordance with figure 1 It can be seen from the sectional view of the section line A-A and B-B) of the valve group 1 that the casing 2 of the valve group 1 is composed of a pilot stage casing 3 and a power stage casing 4 in layers, wherein the pilot stage casing 3 The power stage housing 4 and the power stage housing 4 adjoin one another along a subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com