Nematic liquid crystal composition, and liquid crystal display element incorporating same

A liquid crystal composition and compound technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as poor display, slow response speed, and reduction of VA-type display elements, and achieve excellent display quality and fast response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0222] Hereinafter, examples are given and the present invention will be described in further detail, but the present invention is not limited to these examples. In addition, "%" in the composition of a following Example and a comparative example means "mass %".

[0223] The following abbreviations are used to describe the compounds in the Examples.

[0224] (side chain)

[0225] -n-C n h 2n+1 straight-chain alkyl group with n carbon atoms

[0226] n-C n h 2n+1 - straight-chain alkyl group with n carbon atoms

[0227] -On-OC n h 2n+1 straight-chain alkoxy group with n carbon atoms

[0228] nO-C n h 2n+1 O- straight-chain alkoxy group with n carbon atoms

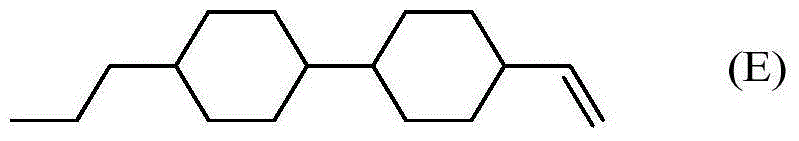

[0229] -V-CH=CH 2

[0230] V-CH 2 =CH-

[0231] -V1-CH=CH-CH 3

[0232] 1V-CH 3 -CH=CH-

[0233] -2V-CH 2 -CH 2 -CH=CH 3

[0234] V2-CH 3 =CH-CH 2 -CH 2 -

[0235] -2V1-CH 2 -CH 2 -CH=CH-CH 3

[0236] 1V2-CH 3 -CH=CH-CH 2 -CH 2

[0237] (ring structure)

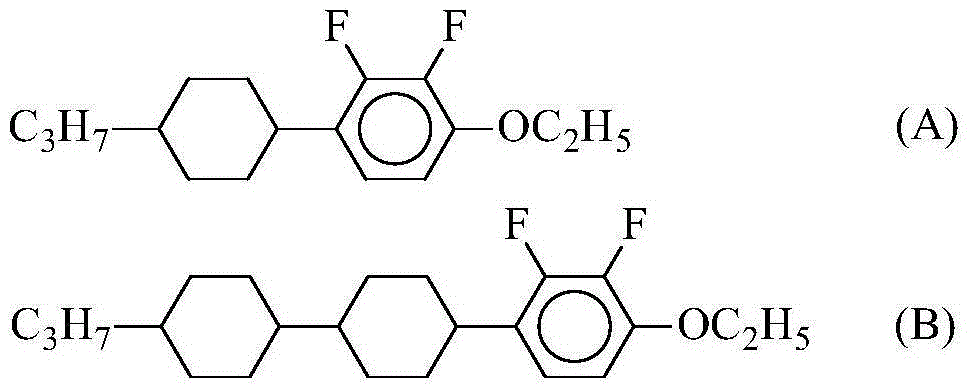

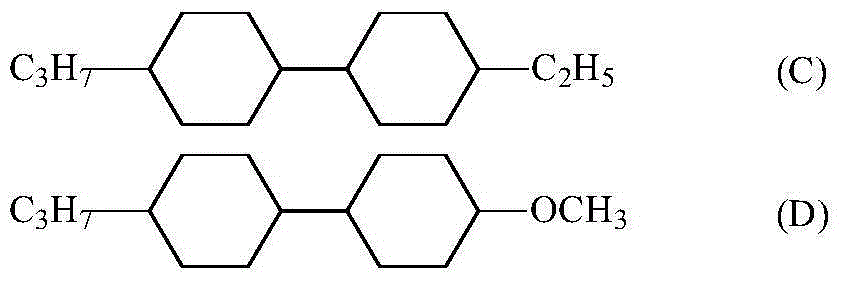

[0238] [chem 42]

[0239]

[0...

Embodiment 3~ Embodiment 6

[0261] In order to confirm the difference in tendency caused by the composition system, LC-3 (Example 3), LC-4 (Example 4), LC-5 (Example 5) and LC-6 (Example 6) containing polymerization The liquid crystal composition of the active compound was measured for its physical property value. Table 2 shows the composition of the liquid crystal composition containing the polymerizable compound and the results of its physical properties.

[0262][Table 2]

[0263]

[0264] These liquid crystal compositions containing a polymerizable compound were injected into a cell with ITO coated with a polyimide alignment film for inducing vertical alignment and subjected to a rubbing treatment with a cell gap of 3.5 μm by a vacuum injection method. Apply a 5.0V square wave, and adjust the irradiation intensity on the surface of the unit to 100mW / cm using a high-pressure mercury lamp through a filter that filters out ultraviolet rays below 320nm 2 And UV irradiation was performed, and the ver...

Embodiment 7~ Embodiment 12

[0269] In order to confirm the difference in tendency due to the type of monomer, LC-7 (Example 7) and LC-8 in which various monomers were added were prepared by setting the host liquid crystal (host liquid crystal) used in Example 2 as LCX. (Example 8), LC-9 (Example 9), LC-10 (Example 10), LC-11 (Example 11) and LC-12 (Example 12) liquid crystal compositions containing polymerizable compounds , to measure its physical properties. Table 3 shows the composition of the liquid crystal composition containing the polymerizable compound and the results of its physical properties.

[0270] [table 3]

[0271]

[0272] These liquid crystal compositions containing a polymerizable compound were injected into a cell with ITO coated with a polyimide alignment film for inducing vertical alignment and subjected to a rubbing treatment with a cell gap of 3.5 μm by a vacuum injection method. Apply a 5.0V square wave, and adjust the irradiation intensity on the surface of the unit to 100mW...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com