Helical reinforcement bending equipment

A spiral steel bar bending technology, applied in the field of spiral steel bar bending equipment, can solve problems such as low operating efficiency, high labor intensity, and troublesome reinforcement cage binding, and achieve the effects of saving labor, saving consumption, and accelerating bending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

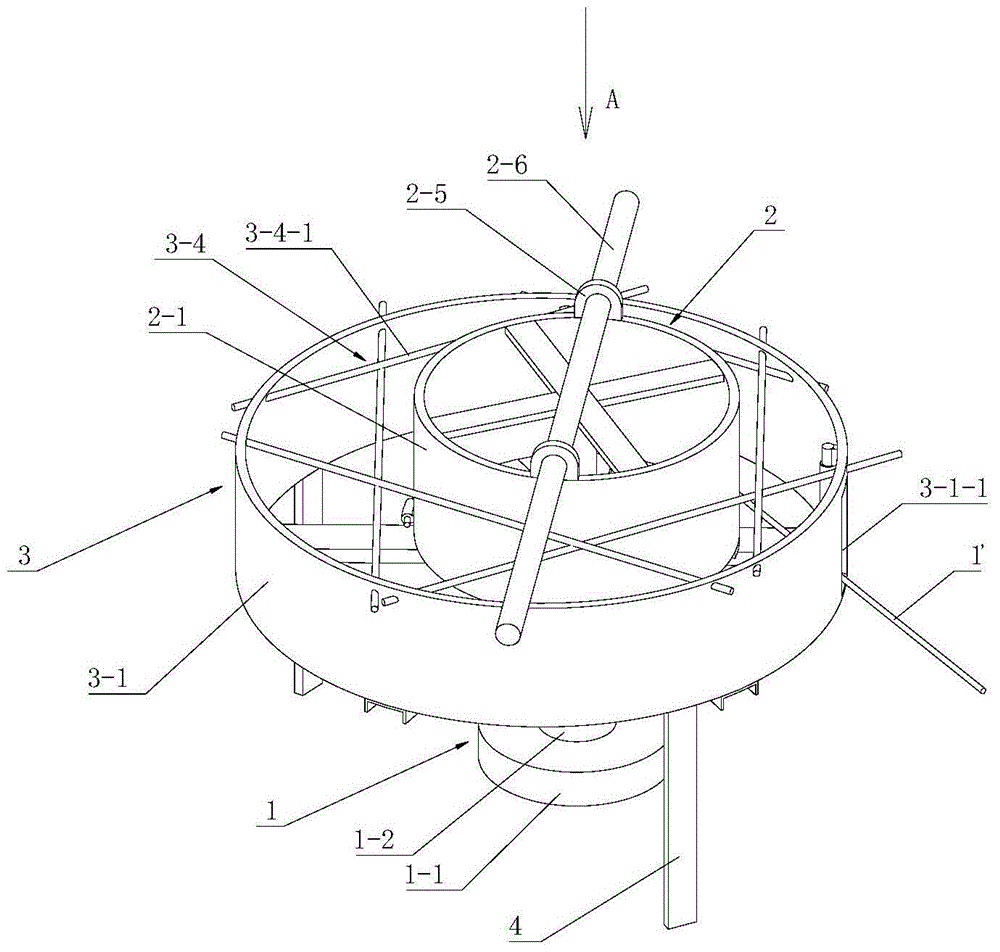

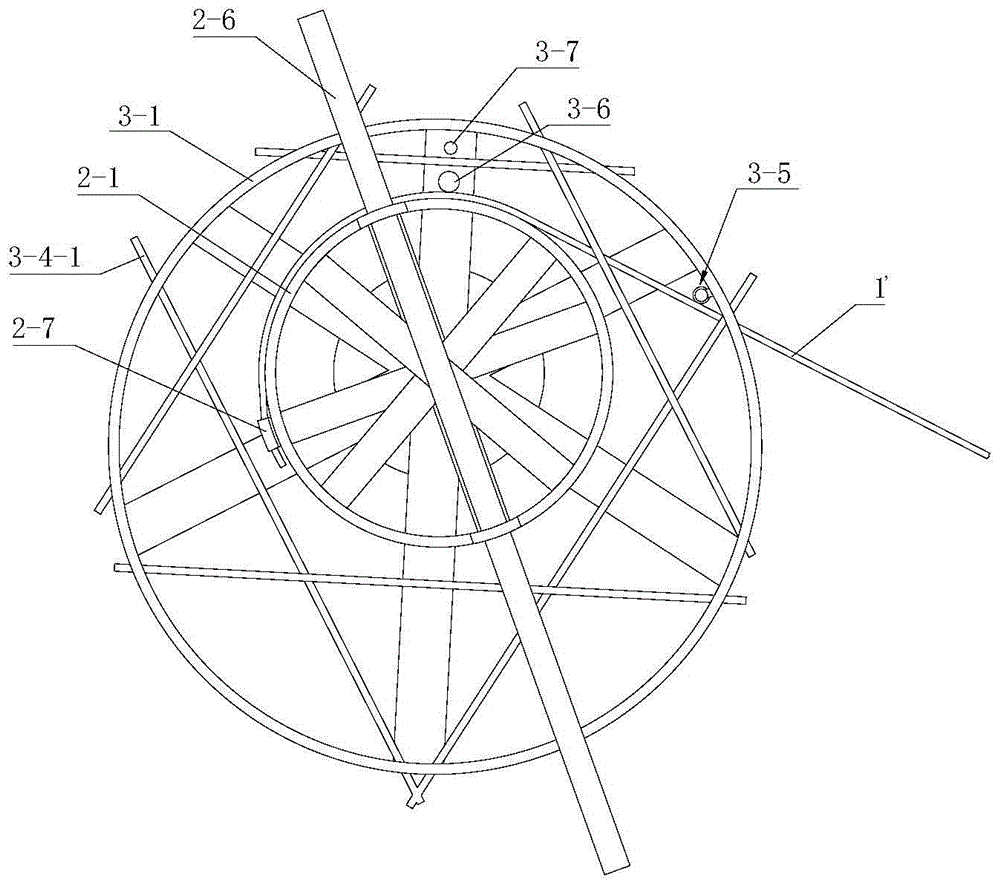

[0023] see Figure 1-5 , a spiral steel bar bending equipment is composed of a base frame part 1, a bending execution part 2 and a formed steel bar storage part 3.

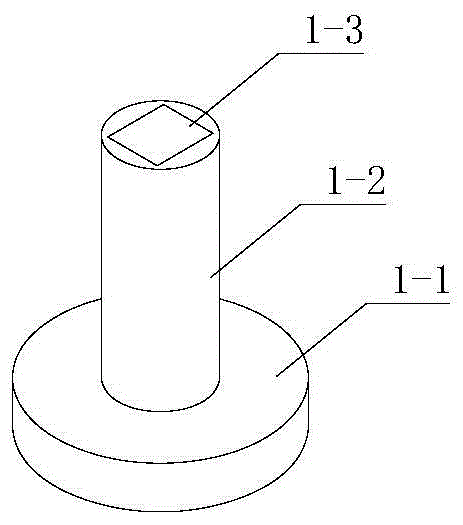

[0024] The pedestal part includes a base 1-1 and a column 1-2 fixedly supported on the base.

[0025] The bending execution part includes a rotating drum 2-1, and a rotating sleeve 2-2 is arranged at the center of the rotating drum. The bracket 2-4 is connected with the rotating drum, and two lugs 2-5 with sockets are arranged on the top of the rotating drum, and a push bar 2-6 is inserted in the two lugs, and the outer wall of the rotating drum An end fixing structure 2-7 for fixing the ends of the reinforcing bars is provided on the top.

[0026] The forming storage part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com