Bag making device

A bag-making device and heat-sealing device technology, applied in packaging and other directions, can solve the problems of increased meeting, reduced work efficiency, and difficulty in grasping the cut end of the packaging film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

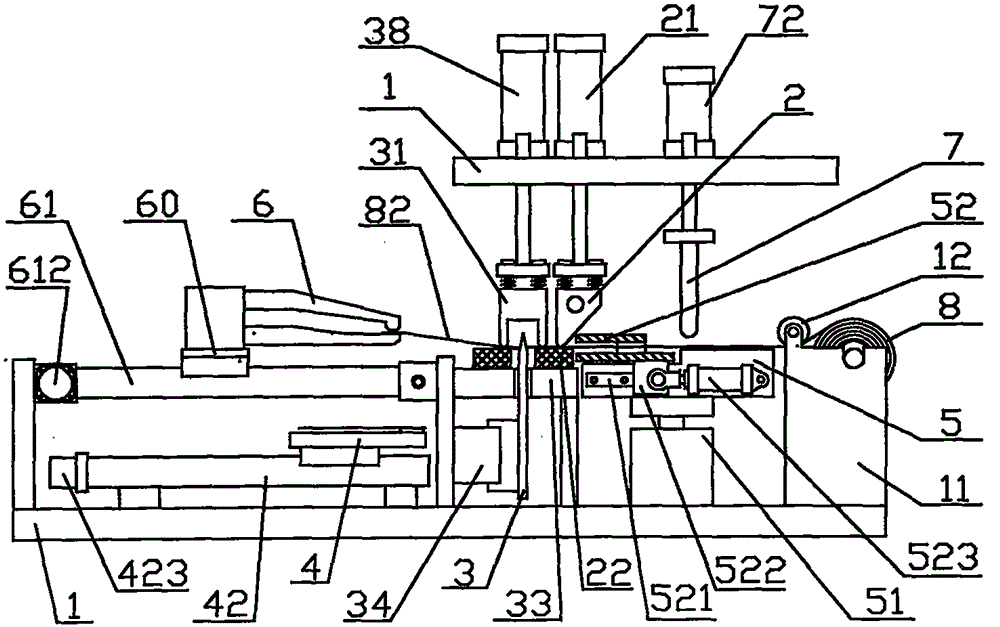

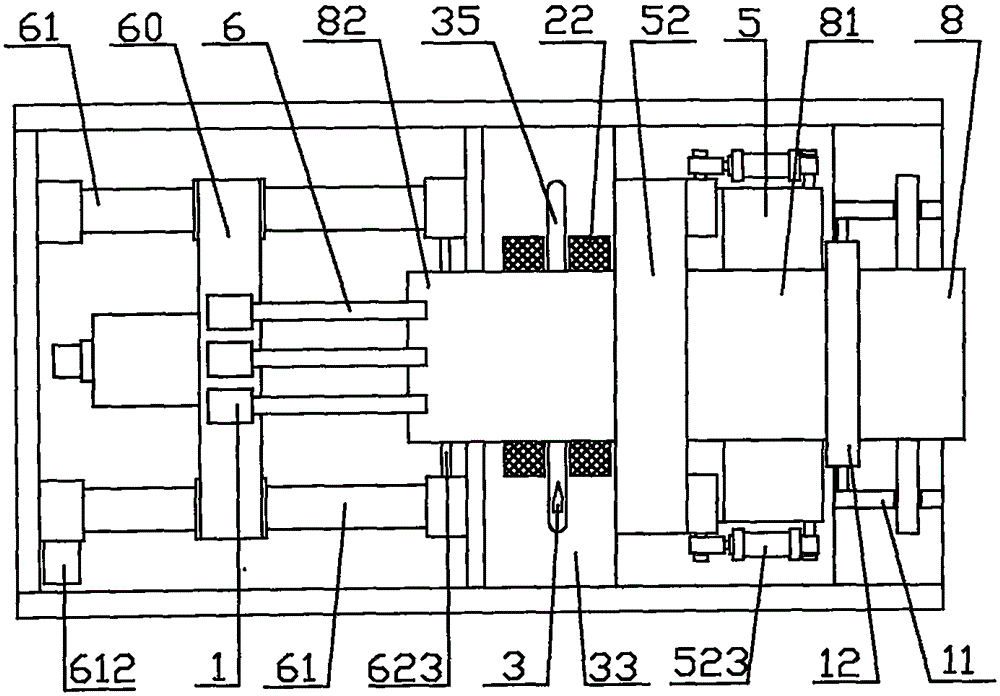

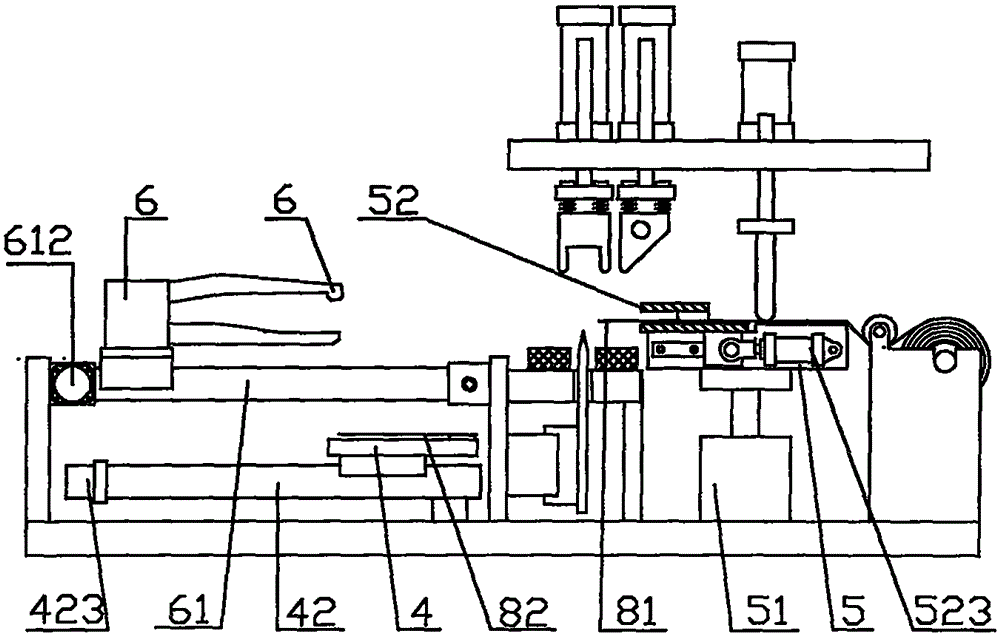

[0040] Embodiment 1: as Figure 1-Figure 8 Shown: front and rear in the present invention refer to the order from left to right in the figure, that is, the left side of the figure is the front in this description.

[0041] Install two U-shaped baffles on the left and right of the rear end of the frame 1, and set a round shaft in the two U-shaped grooves. One end of the round shaft is processed into an annular groove, and the film roll 8 is installed on the round shaft. In the middle section of the middle section, the groove of the circular shaft is placed in the U-shaped groove of the baffle plate, and a guide roller or a stop bar 12 parallel to the die roll 8 is arranged on the front side of the two baffle plates to form a film roll frame 11. The two ends of the circular shaft rotate in the U-shaped groove of the baffle with a certain frictional force to form damping, so that the bag-drawing manipulator 6 tightens the packaging film 81 during the bag-drawing process. The film...

Embodiment 2

[0049] Embodiment 2: as Figure 10 As shown: the difference between embodiment 2 and embodiment 1 is that the bag feeding mechanism is composed of an optical axis 62, a linear bearing 621, and a rodless cylinder 63; the cutting device is composed of a moving knife 36, a fixed knife 37, and a cutting cylinder 38 The fixed bag mechanism is made of cylinder 43, rocking arm 432, pressure bar 431; The bag pressing mechanism is made of pressure roller 71, rocking arm 721; set down.

[0050] An optical axis 62 is respectively installed on both sides of the frame in front of the cutting seat 33, linear bearings 621 are respectively installed on the two optical axes 62, and a bag-drawing manipulator is installed on the two linear bearings 621 on the two optical axes 62 via a beam 6. Install a rodless cylinder 63 parallel to the optical axis 62 on the inner side of the optical axis 62, and connect the cylinder slider 631 of the rodless cylinder 63 with the linear bearing.

[0051] The...

Embodiment 3

[0055] Embodiment 3: as Figure 12 As shown: the difference between embodiment 3 and embodiment 1 and embodiment 2 is that: the electric slide table 61 is lengthened and extends forward, the bag storage tray 4 is set forward and installed under the front end of the frame 1, and the delivery is omitted. Bag running mechanism; the bag storage tray 4 can also be a bag taking device on the packaging machine, or a lifting tray on the packaging machine.

[0056] The bag pressing mechanism is composed of a pressure roller 71 and a guide rod 723. The two ends of the rotating shaft of the pressure roller 71 are installed on the guide rod seat 722 with brackets, and the two guide rods 723 are slidably installed on the upper frame. Set 724. The positions of the heat-sealing device and the cutting device are mutually converted. The heat sealing cylinder 21 and the heat sealing knife 2 of the heat sealing device are installed in front of the cutting cylinder 38 and the concave pressing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com