Test tube rack storage and transportation device

A test tube rack and bottom plate technology, which is applied in the field of test tube rack storage and transportation devices, can solve problems such as inability to use instruments together, and achieve the effects of reducing the risk of overturning and pollution and preventing repeated taking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

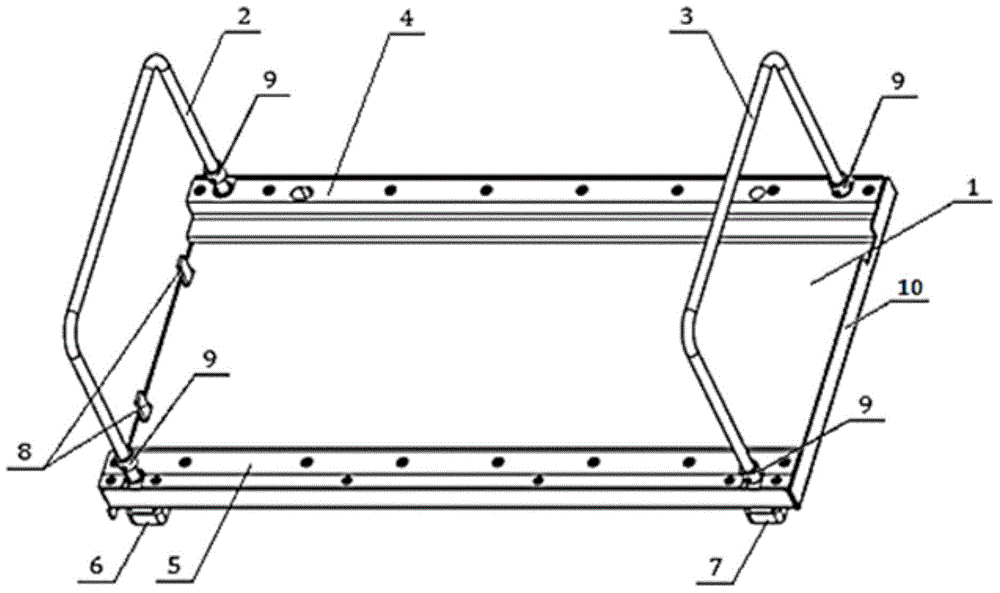

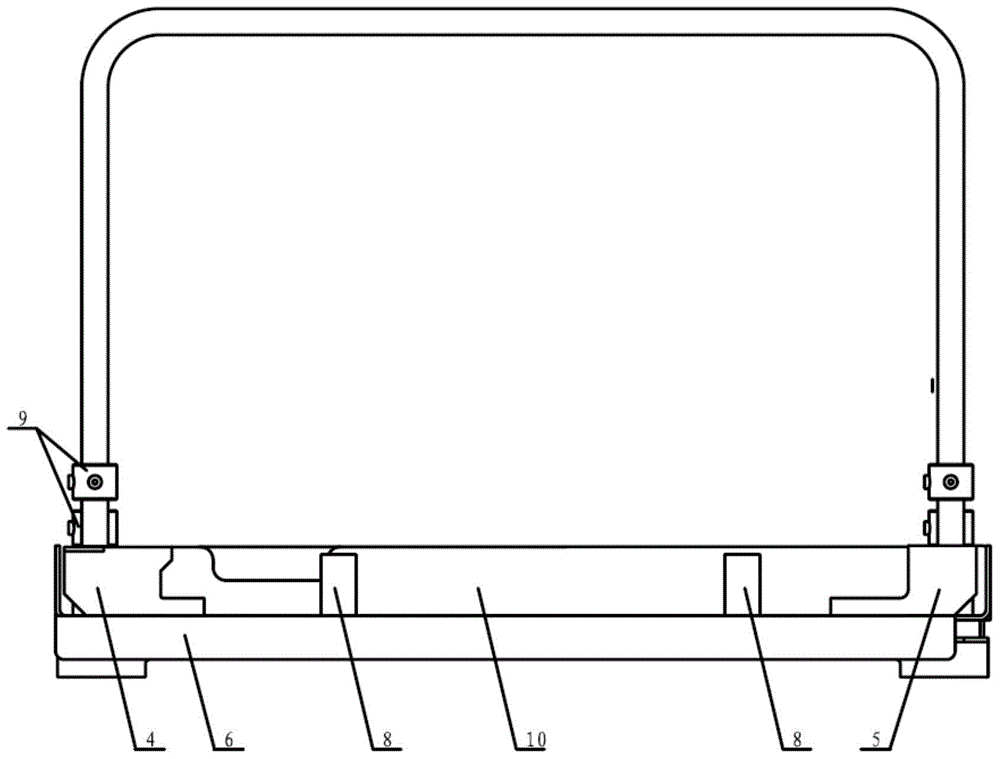

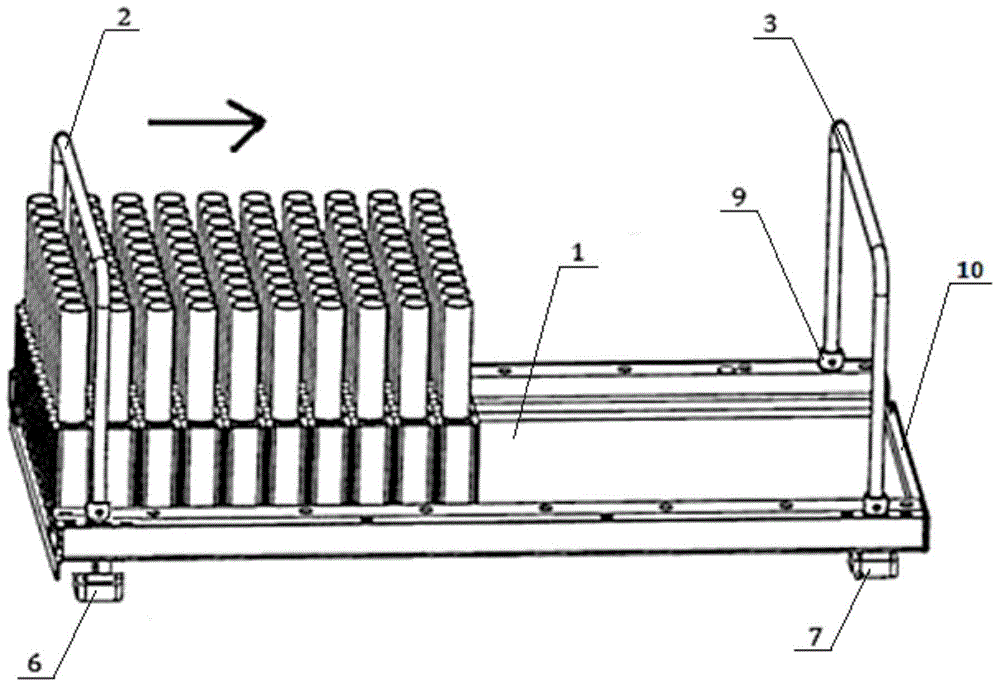

[0020] Such as Figure 1 to Figure 5 As shown, this embodiment includes: a base plate 1, a front handle 2, a front support bar 6 corresponding to the front handle 2, a rear handle 3 and a rear support bar 7 corresponding to the rear handle 3, wherein: the front handle 2 The left and right ends of the handle pass through the base plate 1 and link to each other with the front support bar 6, and the left and right ends of the rear handle 3 pass through the base plate 1 and link to each other with the rear support bar 7, and the left and right ends of the front and rear handles are all fixed with a limit block 9.

[0021] The front support bar 6 is provided with a stopper 8, and the number of the stoppers 8 is preferably two, which are symmetrically distributed on the front support bar 6;

[0022] The bottom plate 1 includes: a left guide bar 4 , a right guide bar 5 and a channel corresponding to the blocking piece 8 of the front support bar 6 .

[0023] The bottom plate 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com