S-type stainless steel hanging code

A stainless steel, hanging code technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of heavy workload, inconvenient installation, copper pipes and water pipes falling off, saving installation space, convenient The effect of adjusting the top support and improving the installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

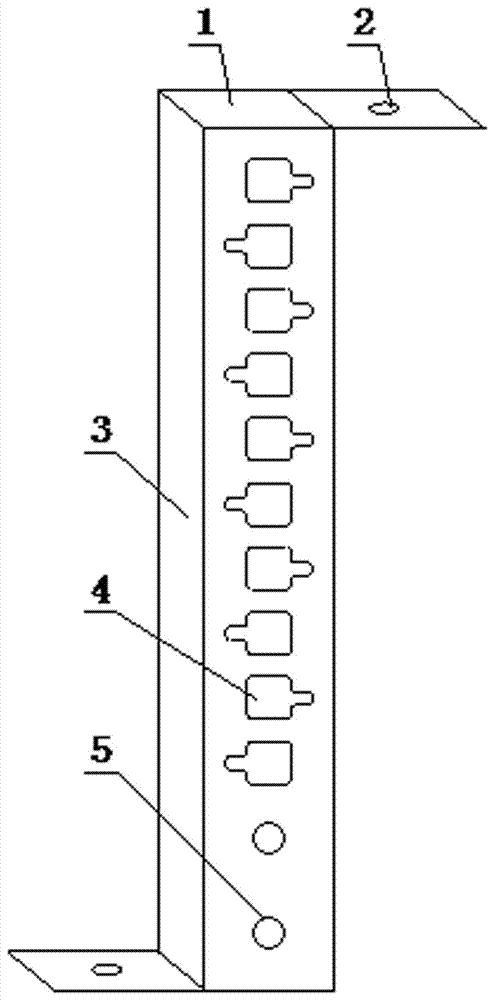

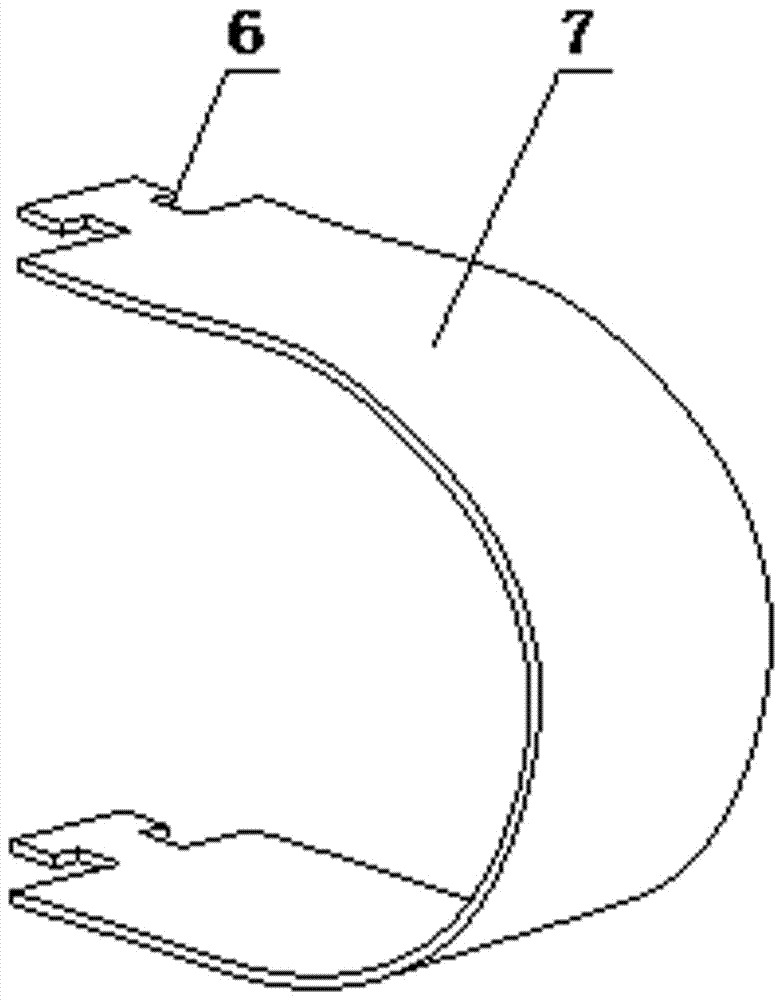

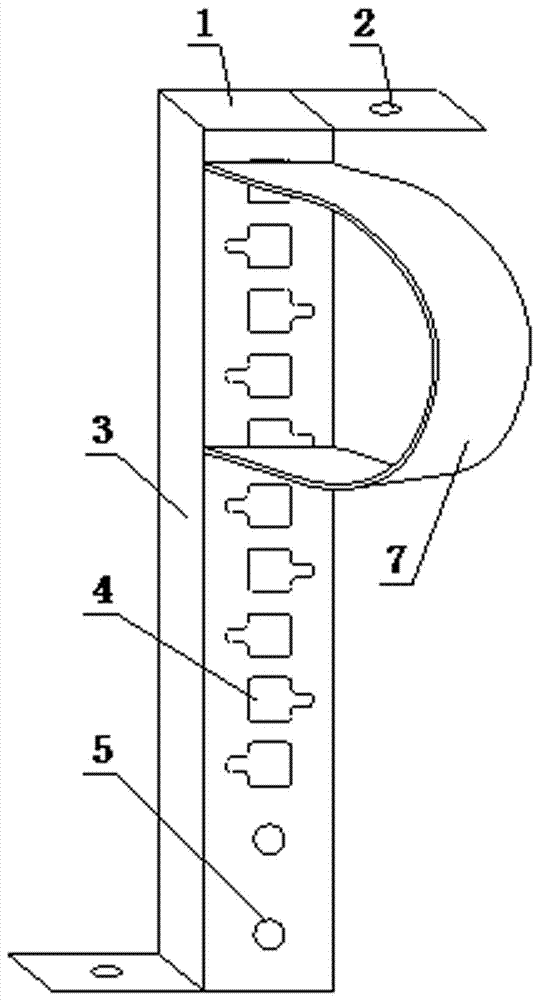

[0029] see figure 1 , figure 2 , image 3 As shown, the S-type stainless steel hanging code includes a support frame, a semicircular cover card 7 and a PVC seat card. The support frame includes a support body 3 and a fixed piece 1. The support body 3 is a columnar stainless steel support body with a square cross section. , the two ends of the support body 3 are oppositely angled with a fixed piece 1 protruding outside the support body 3, and the fixed piece 1 is a rectangular stainless steel fixed piece that is provided with a fixing hole 2 at the end far away from the support body 3. The body 3 is provided with a plurality of uniformly arranged through holes to form a cover card slot 4. The cover card slot 4 is a polygon with at least two openings parallel to the protruding direction of the fixed piece 1. The cover card slot 4 has a side convex The protruding direction of the protruding head of the cover card slot 4 is parallel to the protruding direction of the fixed piec...

Embodiment 2

[0033] see Figure 4 , Figure 5 As shown, the S-type stainless steel hanging code includes a support frame, a semicircular cover card 14 and a PVC seat card. The semicircular cover card 14 is a semi-cylindrical sheet-shaped stainless steel semicircular cover card. , the support body 10 is a columnar stainless steel support body with a square cross section, and the two ends of the support body 10 are oppositely connected with a fixed piece 8 protruding from the outside of the support body 10, and the fixed piece 8 is far away from the support body The 10 end is provided with the rectangular stainless steel fixing piece of fixing hole 9, and described support body 10 is provided with a plurality of evenly arranged through holes to form cover card groove 11, and cover card groove 11 is to have at least two orifice sides and fixed piece 8 protruding. A polygon with a direction parallel to the output, the cover card slot 11 is a rectangular through hole whose long side is paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com