Expansion curve analysis method for steel critical point test and use thereof

A technology of expansion curve and analysis method, which is applied in the field of material testing, can solve problems such as unclear physical meaning of key points, systematic errors, subjective factors, etc., and achieve the effect of improving the degree of objective quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a chemical composition of 0.060%C, 0.33%Si, 1.51%Mn, 0.0070%P, 0.0038%S, 0.052%Nb, 0.0019%B, 0.025%Ti, balance Fe and impurities. The method for testing critical points Ac1 and Ac3 of body steel at a heating rate of 0.1°C / s, the steps are as follows:

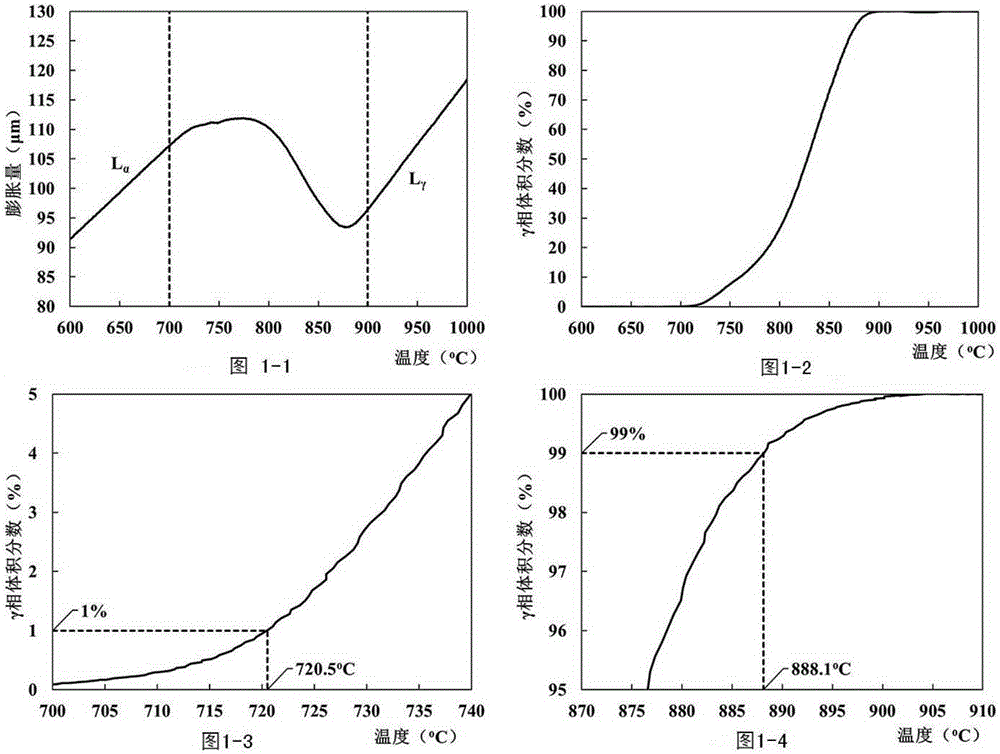

[0026] (1) The dilatometer records a data point every 5s, and draws the expansion curve with the temperature T as the abscissa and the expansion L as the ordinate; figure 1 As shown in (1-1) figure;

[0027] (2) Perform linear fitting on the expansion data in the temperature range of 600~700℃ and 900~1000℃, and obtain the linear equation Lα=0.1589T-3.9032 and Lγ=0.2199T-101.46;

[0028] (3) Calculate the high-temperature phase (γ phase) volume fraction Xγ=(Lα-L) / (Lα-Lγ)×100%, draw a curve with T as the abscissa and Xγ as the ordinate; figure 1 As shown in (1-2);

[0029] (4) Select the critical volume fraction C=1%;

[0030] (5) Xγ=1% and Xγ=99% on the Xγ-T curve correspond to T=720.5°C and T=...

Embodiment 2

[0033] This embodiment provides a kind of low-carbon carbon fiber with chemical composition of 0.060%C, 0.33%Si, 1.51%Mn, 0.0070%P, 0.0038%S, 0.052%Nb, 0.0019%B, 0.025%Ti, balance Fe and impurities. The method of testing the critical point Bs and Bf when the steel is cooled at a cooling rate of 25°C / s after holding at 1000°C for 5 minutes, the steps are as follows:

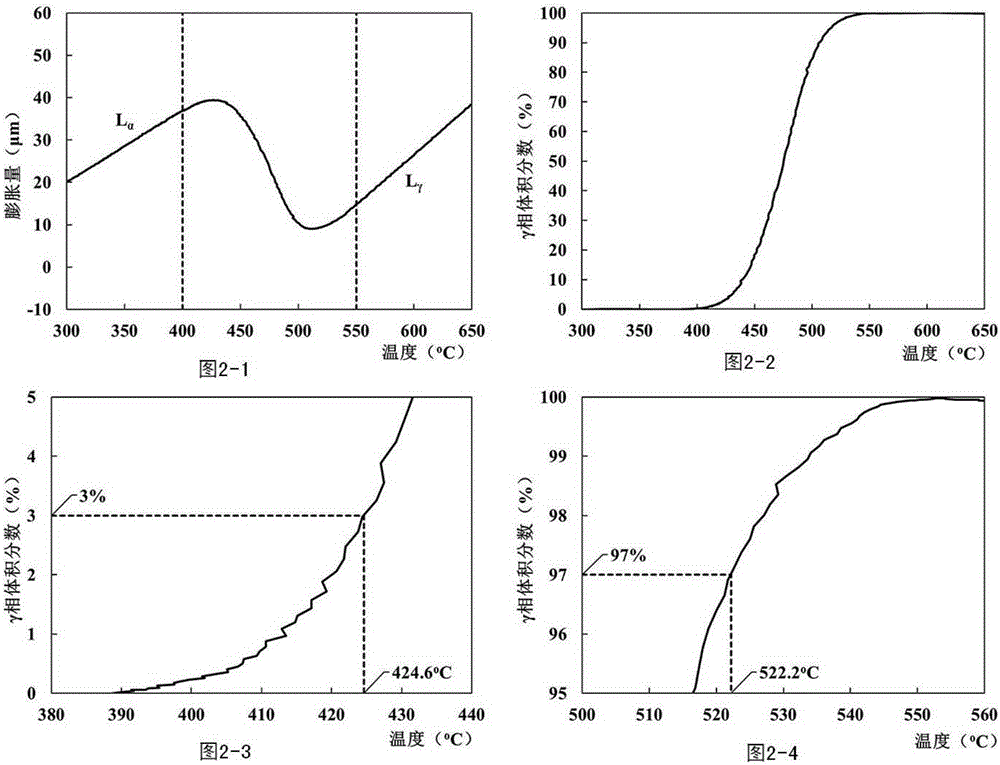

[0034] (1) The dilatometer records a data point every 0.02s, and draws the expansion curve with the temperature T as the abscissa and the expansion L as the ordinate; figure 2 As shown in (2-1) figure;

[0035] (2) Perform linear fitting on the expansion data in the temperature range of 300~400℃ and 550~650℃, and obtain the linear equation Lα=0.1701T-30.988 and Lγ=0.2384T-116.45;

[0036] (3) Calculate the high-temperature phase (γ phase) volume fraction Xγ=(Lα-L) / (Lα-Lγ)×100%, draw a curve with T as the abscissa and Xγ as the ordinate; figure 2 As shown in (2-2);

[0037] (4) Select the critical volume fract...

Embodiment 3

[0041] This embodiment provides a 9Ni steel whose chemical composition is 0.057%C, 0.18%Si, 0.62%Mn, 0.0054%P, 0.0013%S, 9.10%Ni, 0.024%Alt, the balance Fe and impurities at 0.05°C / The method for testing critical points Ac1 and Ac3 under the s heating rate, the steps are as follows:

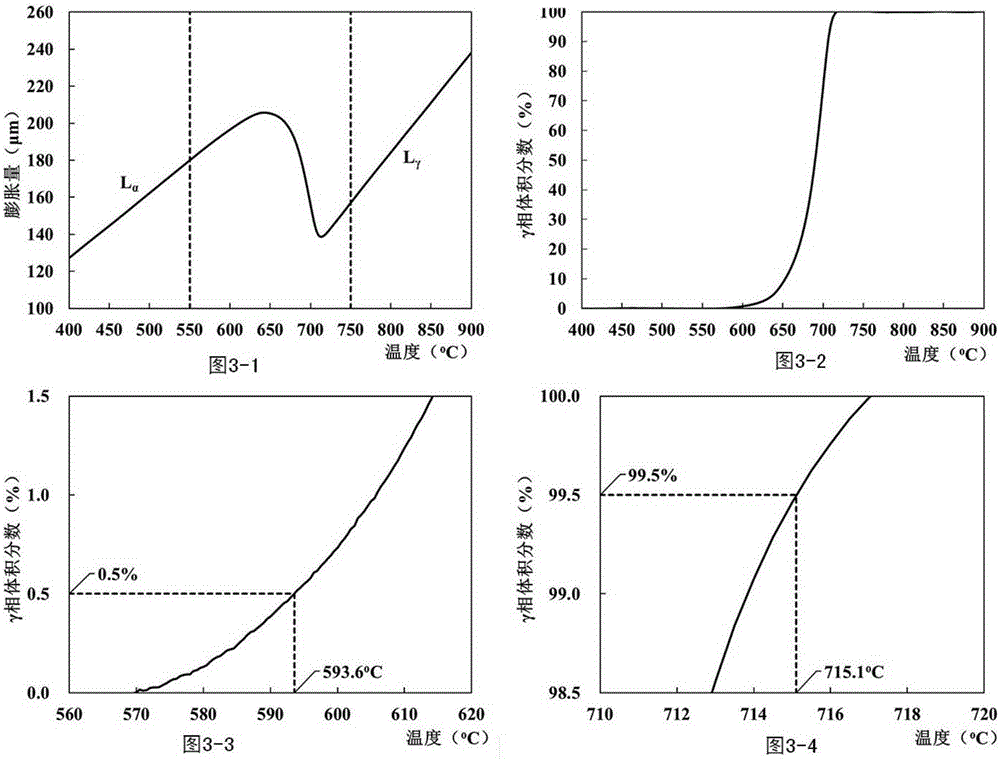

[0042] (1) The dilatometer records a data point every 0.5°C, and draws the expansion curve with the temperature T as the abscissa and the expansion L as the ordinate; image 3 As shown in (3-1) figure;

[0043] (2) Perform linear fitting on the expansion data in the temperature range of 400~550℃ and 750~900℃, and obtain the linear equation Lα=0.3516T-13.479 and Lγ=0.5397T-247.57;

[0044] (3) Calculate the high-temperature phase (γ phase) volume fraction Xγ=(Lα-L) / (Lα-Lγ)×100%, draw a curve with T as the abscissa and Xγ as the ordinate; image 3 As shown in (3-2);

[0045] (4) Select the critical volume fraction C=0.5%;

[0046] (5) Xγ=0.5% and Xγ=99.5% on the Xγ-T curve correspond to T=593....

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com