Large visual field camera calibration method based on four sets of collinear constraint calibration rulers

A camera calibration and collinear constraint technology, applied in the field of visual measurement, can solve problems such as difficult to guarantee measurement accuracy and difficult to process high-precision calibration objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The specific embodiments of the present invention will be described in detail below in conjunction with technical methods and accompanying drawings.

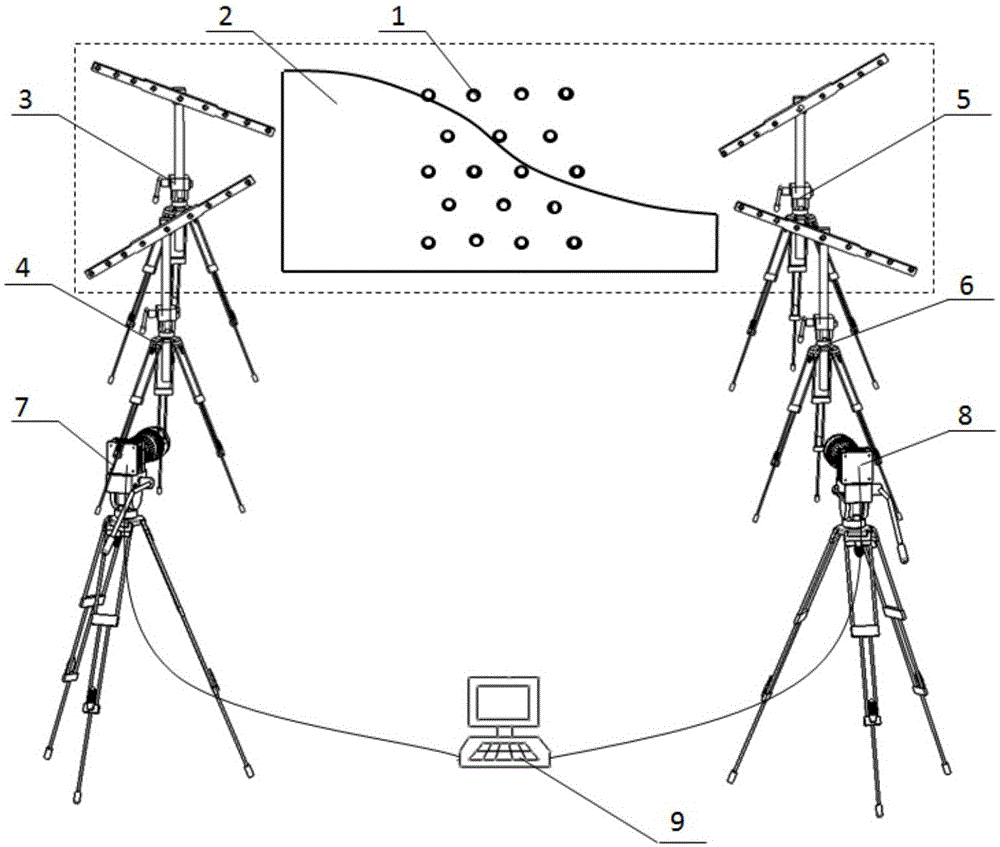

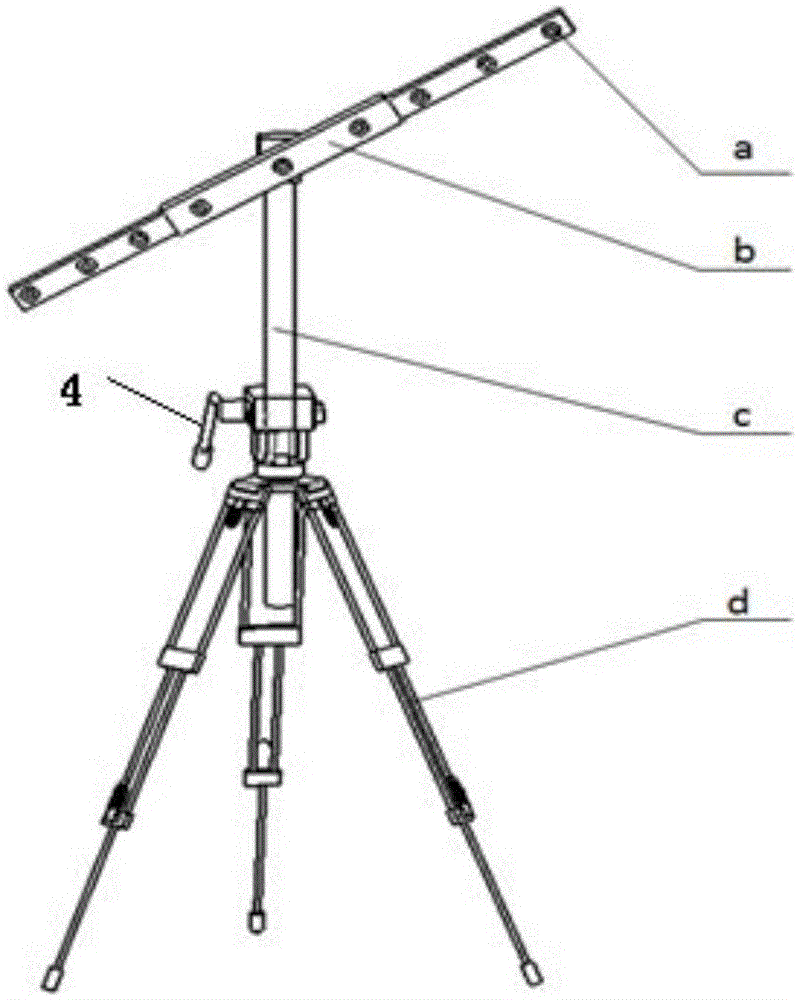

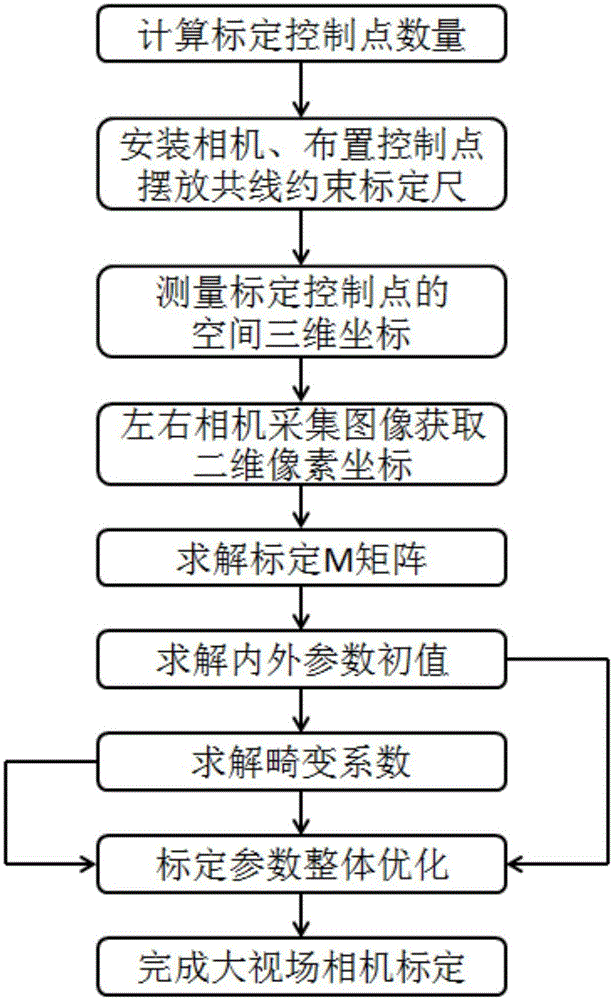

[0073] figure 1 It is a schematic diagram of large field of view camera calibration. In this embodiment, a constrained calibration ruler with collinear measurement marker points is introduced into the large field of view calibration site, and the distortion coefficient is solved by the calibration ruler, and the calibration control points are flexibly arranged according to the principle of space adaptation to solve the calibration. The initial value, and finally optimize the parameters according to the principle of the minimum reprojection error, so as to achieve high-precision calibration of the camera with a large field of view. The initial parameters of camera calibration are solved by arranging a circular calibration control point 1 in the center of the field of view of the measurement site. Since the calibration cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com