DC motor capable of reducing groove frequency radial electromagnetic excitation force

An electromagnetic excitation force, DC motor technology, applied in the direction of DC commutator, electromechanical devices, electrical components, etc., can solve the problems of insignificant chute effect, increased process difficulty, complex process, etc., to reduce the electromagnetic excitation of the stator. force, reduce vibration, reduce the effect of magnetic density change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

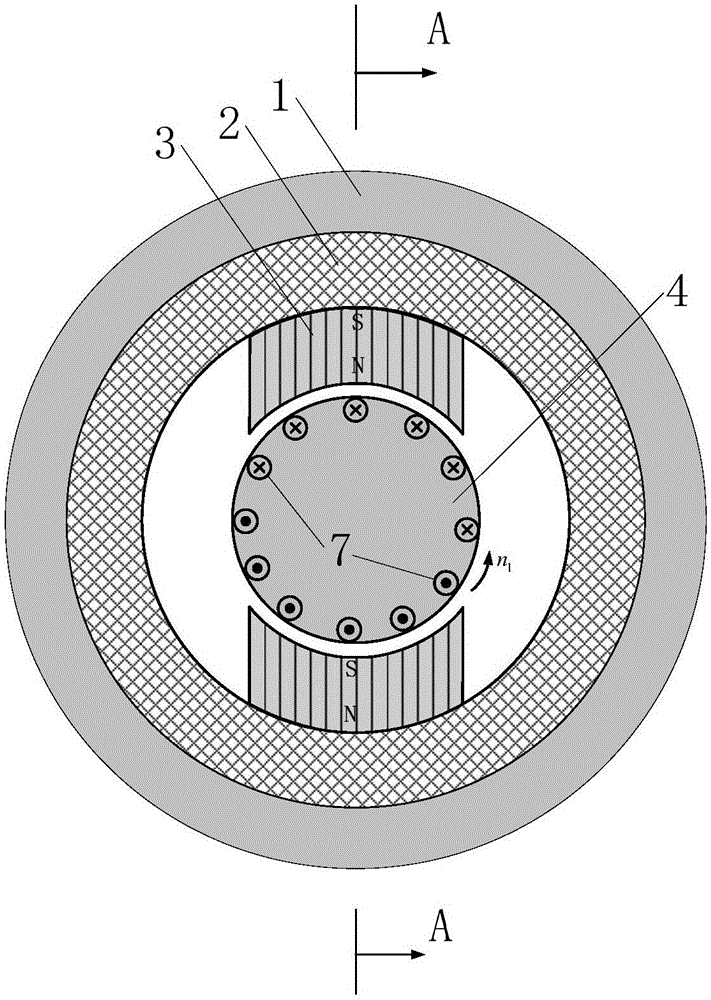

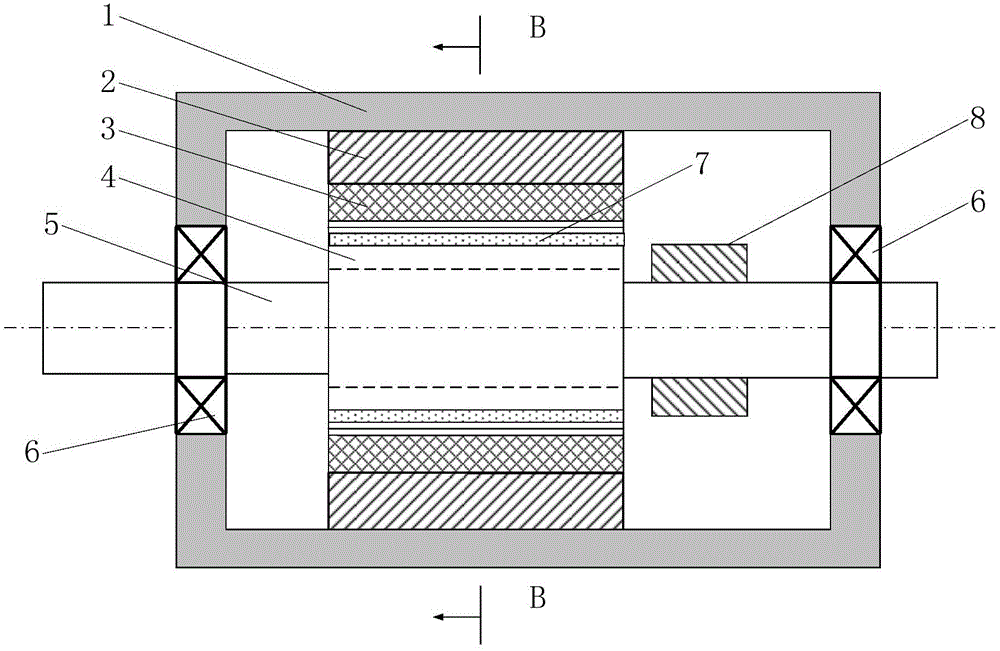

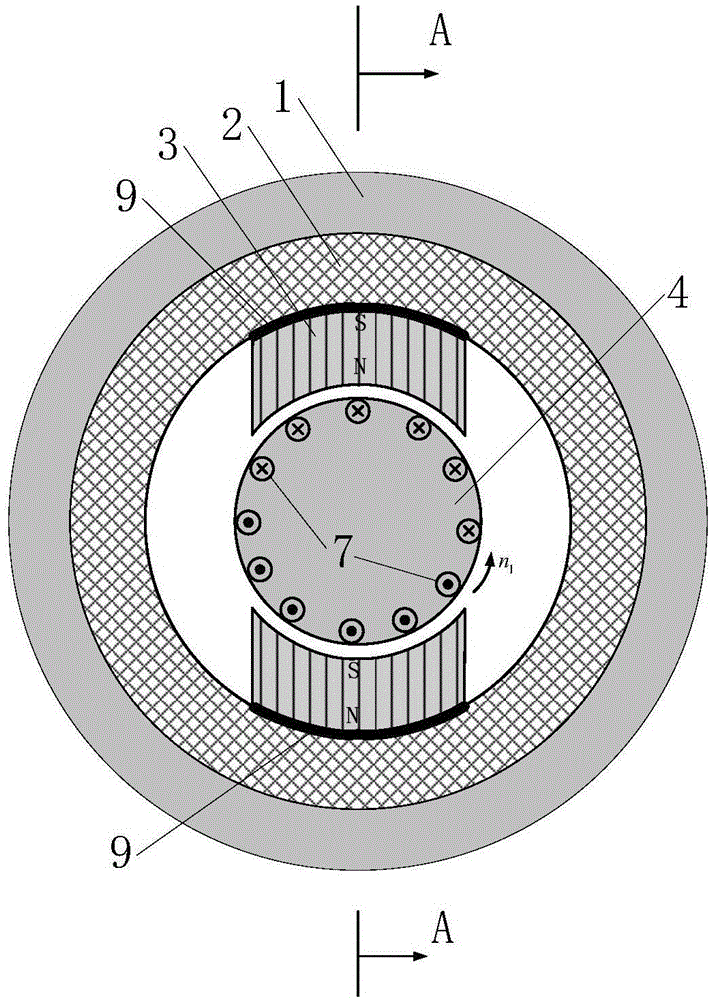

[0029] like figure 1 , figure 2 As shown, the existing permanent magnet DC motor includes a stator base 1, a stator core 2, a stator permanent magnet pole 3, a rotor core 4, a rotor shaft 5, a bearing 6, a rotor armature winding 7 and a commutator 8; Wherein, the stator frame 1 can be fixed by the installation method of a conventional motor, and the stator core 2 is a part of the magnetic circuit of the motor. A stator iron core 2 is fixedly arranged in the stator frame 1 , and a stator permanent magnet pole 3 is fixedly arranged in the stator iron core 2 . Located between the N pole and S pole of the stator permanent magnet pole 3, the rotor core 4 is fixed on the rotor shaft 5, the rotor shaft 5 can drive the rotor core 4 to rotate around the axis, and the rotor shaft 5 is fixed on the stator through the bearing 6 In the machine base 1, several slots (not shown) are evenly opened on the outer circumference of the rotor core 4, and the rotor armature winding 7 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com