A domestic garbage shredder

A domestic garbage and crusher technology, applied in the direction of grain processing, etc., can solve the problems of unsatisfactory crushing and fine crushing effects, poor crushing effect of tough materials, and incomplete crushing methods, etc., to achieve small maintenance and good crushing effect , replace the simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

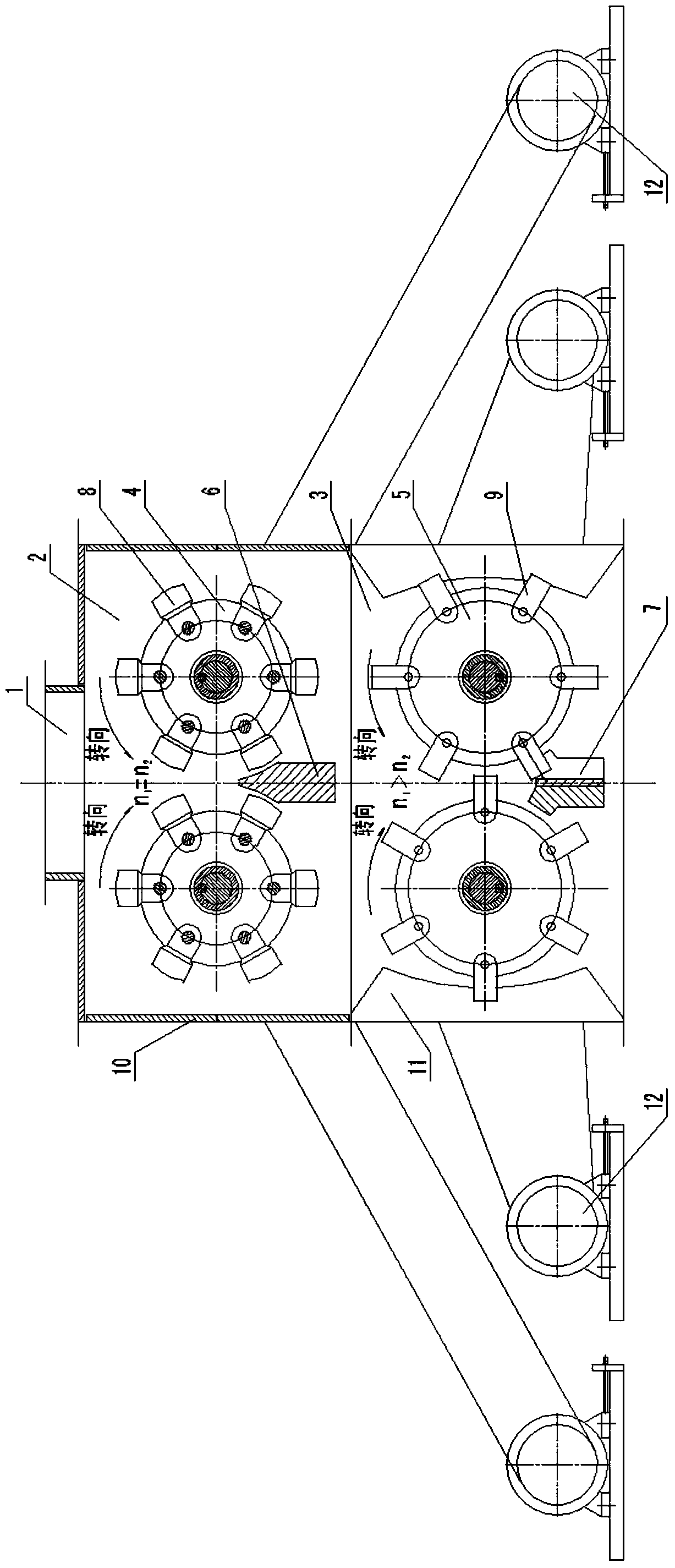

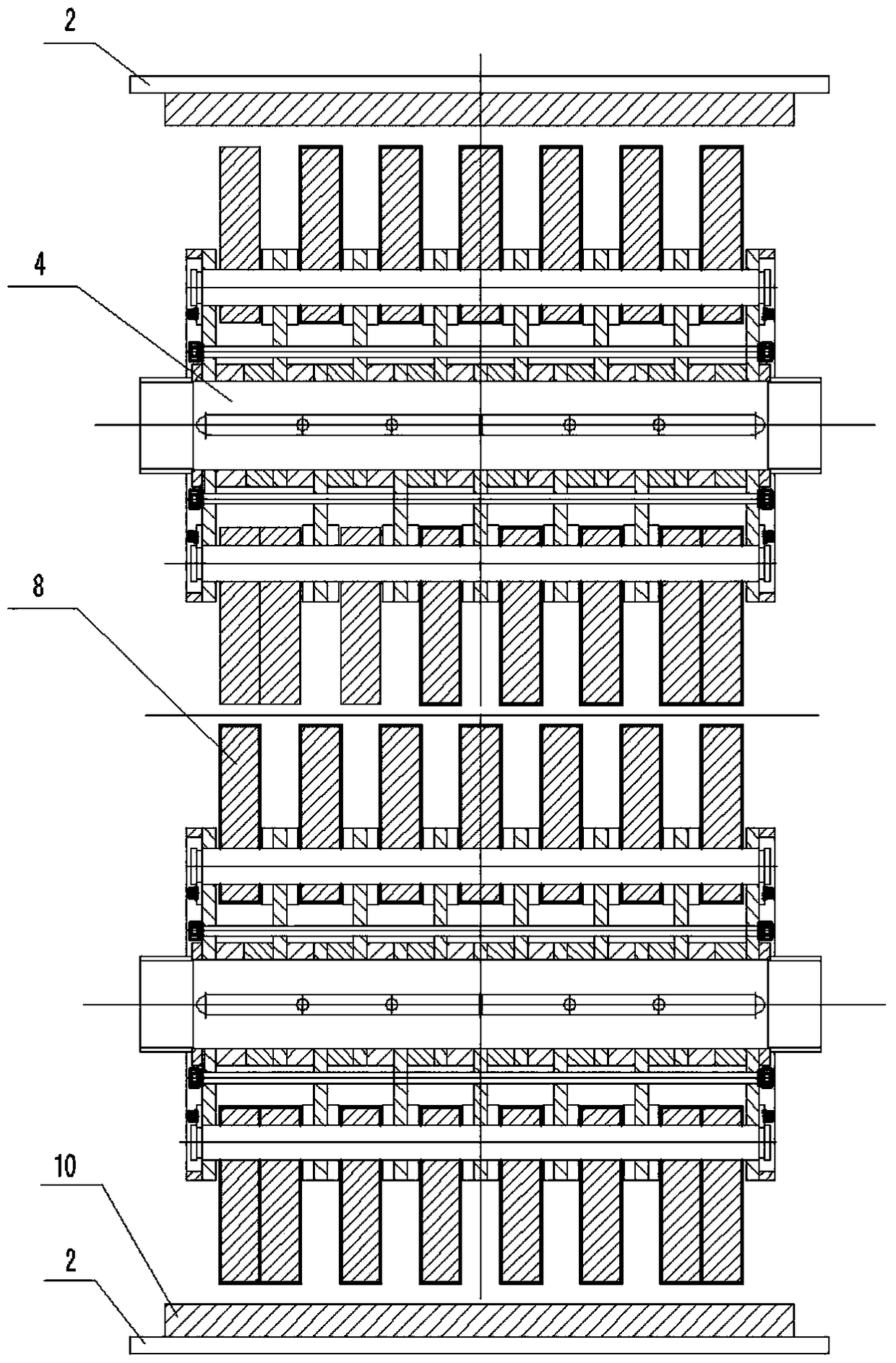

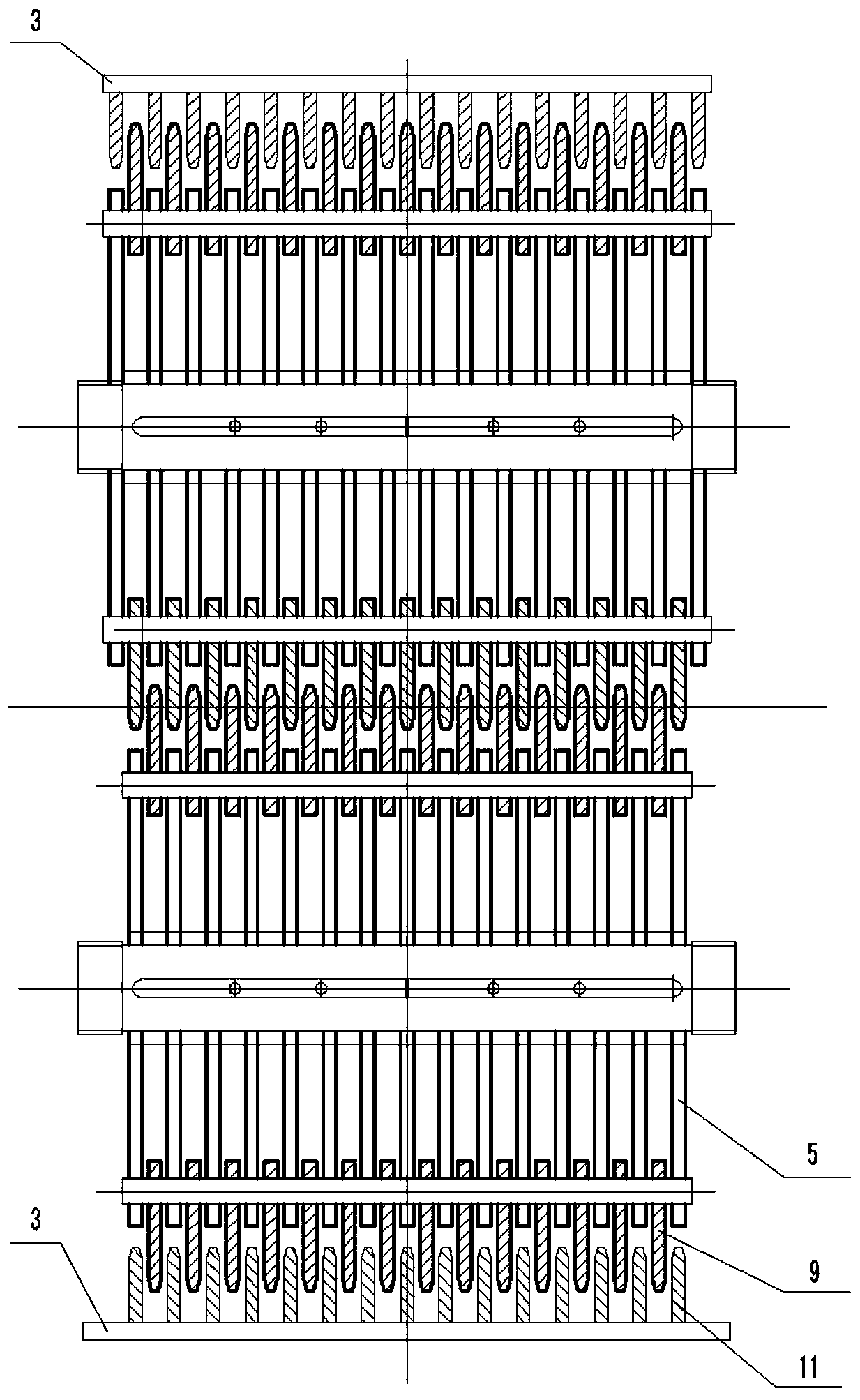

[0024] see figure 1 , figure 2 and image 3 , the structural form of the domestic waste crusher in the present embodiment is:

[0025] The upright crushing box is divided into upper and lower crushing chambers 2 on the upper part and lower crushing chamber 3 on the lower part; the feeding port 1 is set on the top cover of the upper crushing chamber 2, and the The cavity 2 and the lower crushing cavity 3 communicate up and down.

[0026] In the upper crushing chamber 1, a pair of square hammerhead crushing rotors 4 arranged in parallel are arranged horizontally, and a rotatable square hammerhead 8 is hinged on the square hammerhead crushing rotor 4; A hammer anvil 6 is arranged below the crushing rotor 4, and the pair of square hammerhead crushing rotors 4 arranged in parallel are set to rotate in opposite directions at a constant speed.

[0027] In the lower crushing cavity 3, a pair of parallel-arranged sheet-shaped hammer-head crushing rotors 5 are arranged horizontally...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap