Batch positioning auxiliary device for sliding grooves formed in door of subway steel vehicle body

A positioning aid, subway steel technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting production efficiency, poor positioning accuracy, high labor intensity, etc., achieving simple and practical structure and convenient operation. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

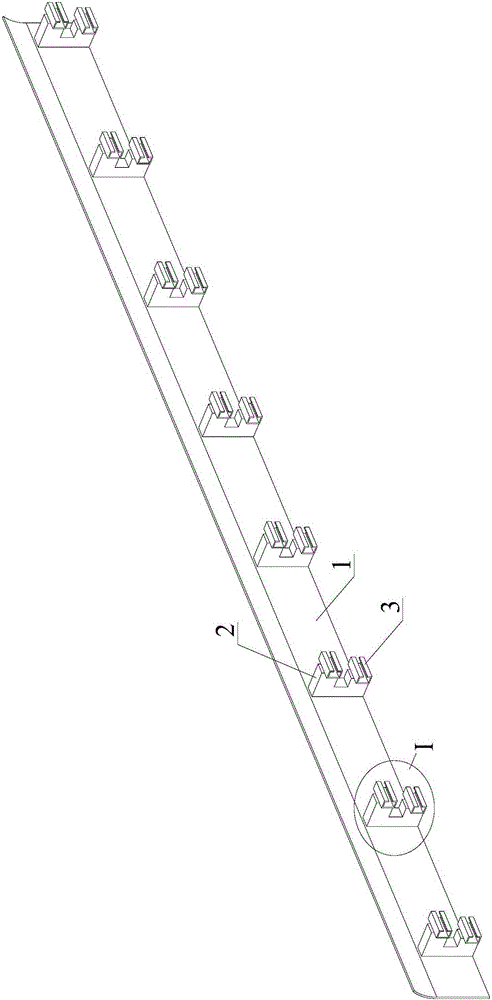

[0021] Such as Figure 4 to Figure 10 As shown, the batch positioning auxiliary device of the chute on the subway steel car body door of the present invention includes a height positioning bracket 4 and a plurality of sliding sample blocks 5, and the horizontal positioning beam 4-1 at the top of the height positioning bracket 4 has a vertical height of 4-1. It is determined by the vertical height of the door frame beam of the subway steel car body door from the floor inside the car.

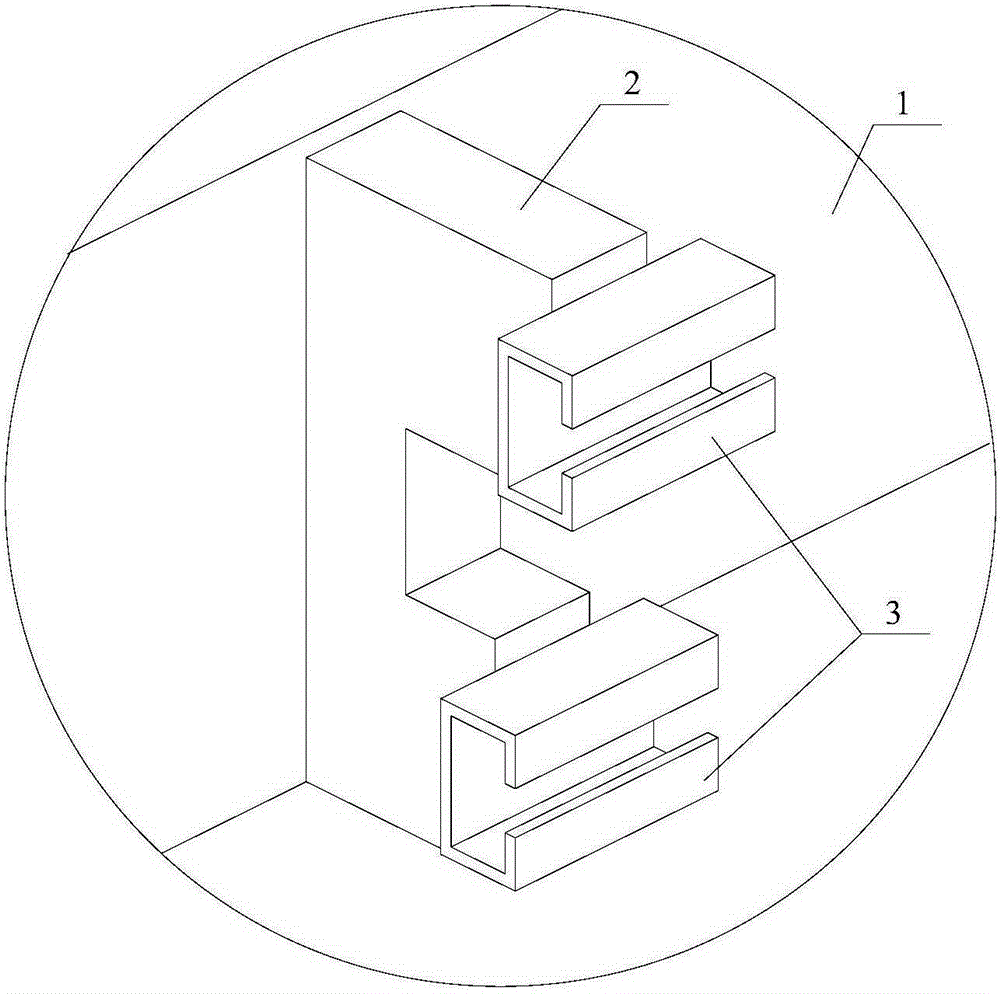

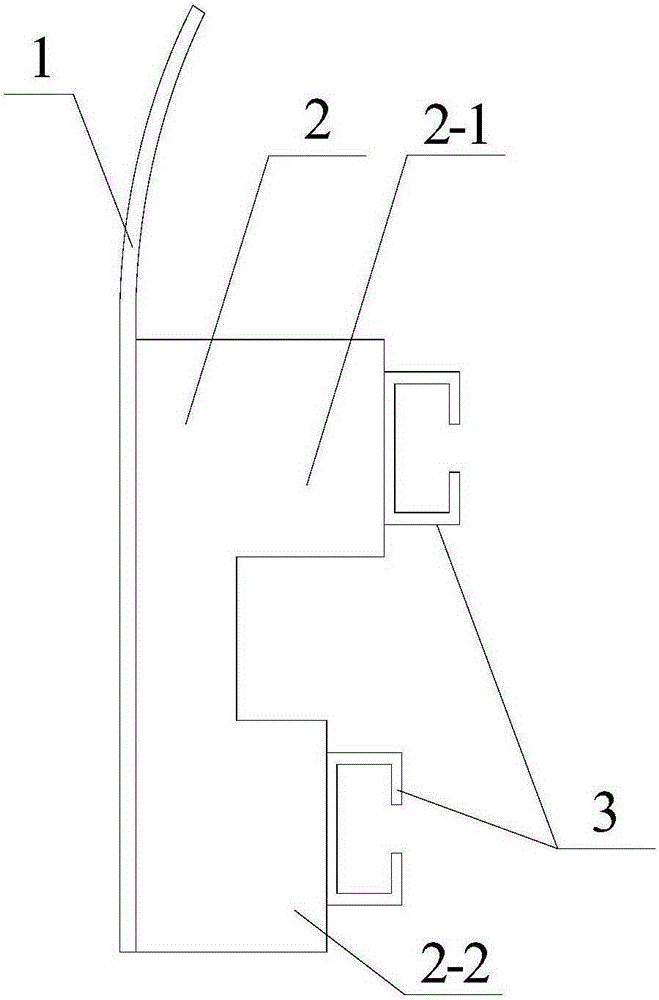

[0022] The sliding sample block 5 includes a vernier positioning seat 5-1, two C-shaped chute locking blocks 5-2, counterbore positioning screws 5-3 and two locking nuts 5-4, and the vernier positioning seat 5 The rear end surface of the middle part of -1 is provided with a vernier sliding slot 5-1-1 matching the outer contour of the horizontal positioning beam 4-1, and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com