Efficient workpiece hot melting machining method

A technology for processing workpieces and workpieces, applied in the field of hot-melt processing, can solve problems such as instability, easy-to-move processing quality, lack of positioning structures for workpieces, etc., and achieve the effects of accelerating efficiency, improving processing efficiency, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

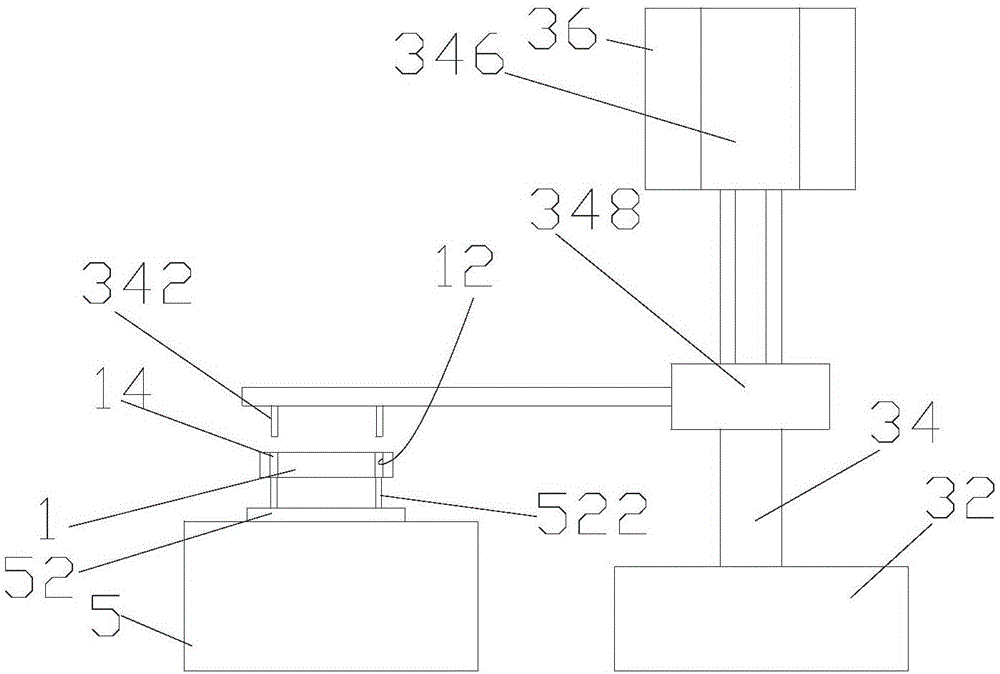

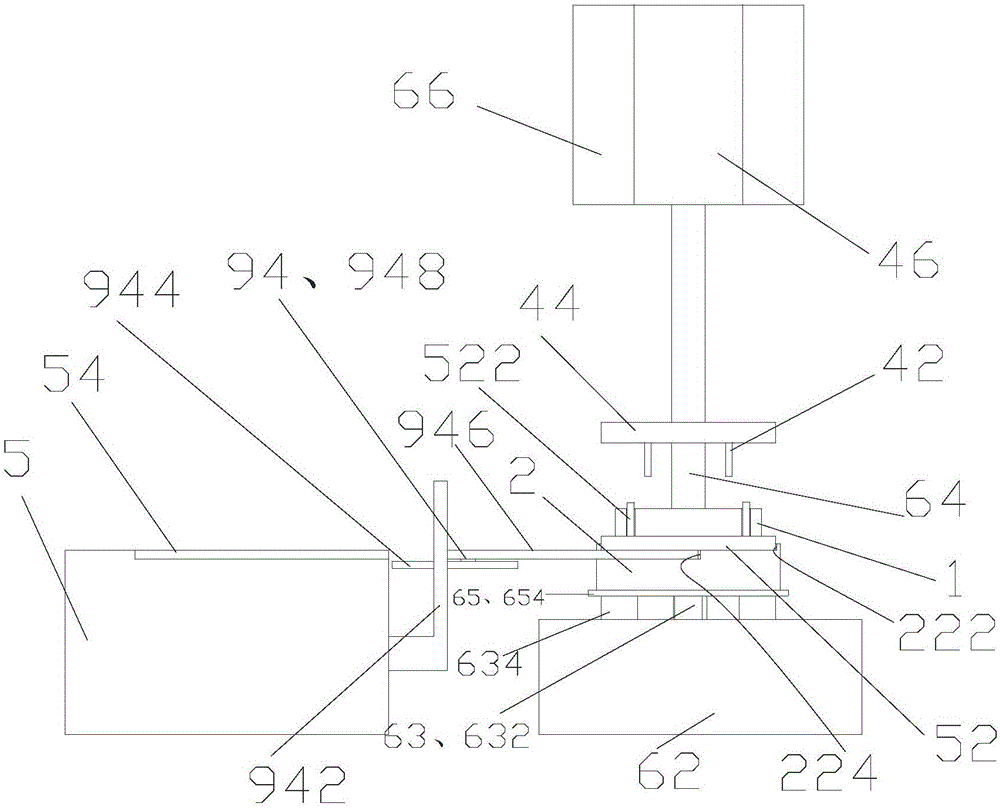

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0030] The efficient hot-melt processing workpiece method described in a preferred embodiment of the present invention mainly utilizes Figure 1-5 The hot melt device shown works.

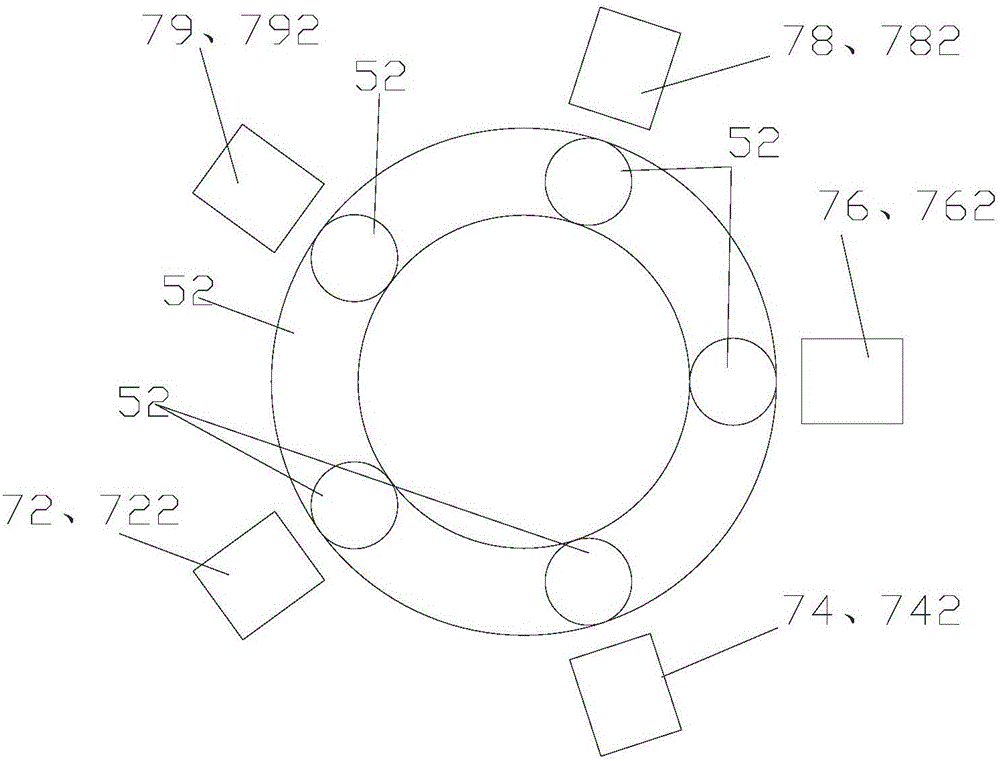

[0031] The hot-melt device comprises an endless transfer mechanism 5, five workbenches 52 are successively arranged on the annular transfer mechanism 5, and a first station 72, a second station 74, a third Station 76, fourth station 78 and fifth station 79. Wherein, the first station 72 is used for loading the workpiece 1, the second station 74 is used for connecting the workpiece 1 and the workbench 52 at the second station 74, and the third station 76 is used for processing the workpiece 1,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap