Automatic strapping device and apparatus for sewing shoulder girdle head passing lingerie buckles

An automatic strapping and strapping technology, which is applied to the parts of strapping machines, strapping materials, sewing equipment, etc., can solve the problems of missing buckles in bundled shoulder straps, low production efficiency, waste of human resources, etc., to reduce production cost, increase production efficiency, and increase the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

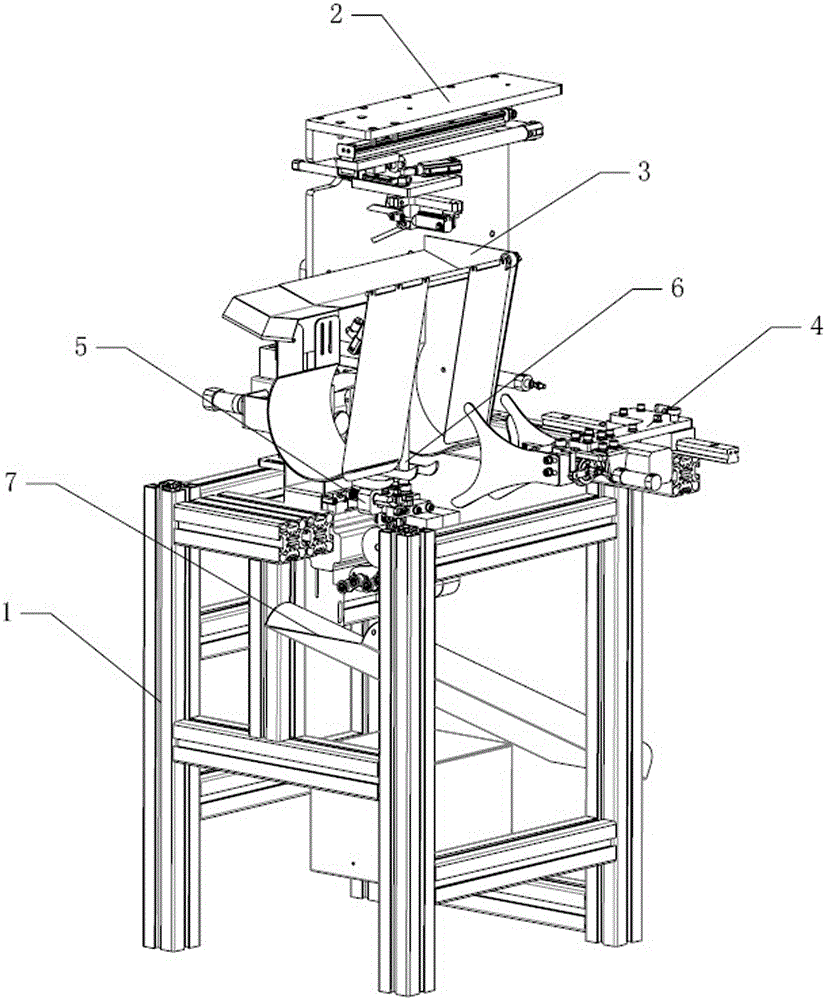

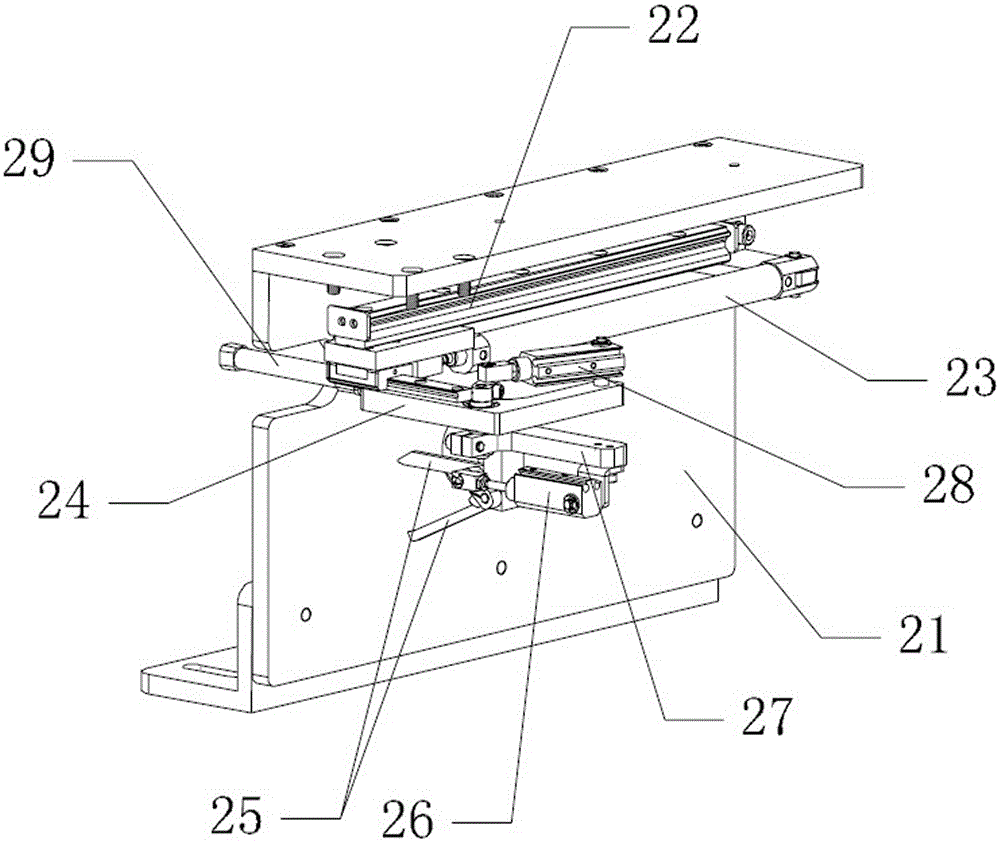

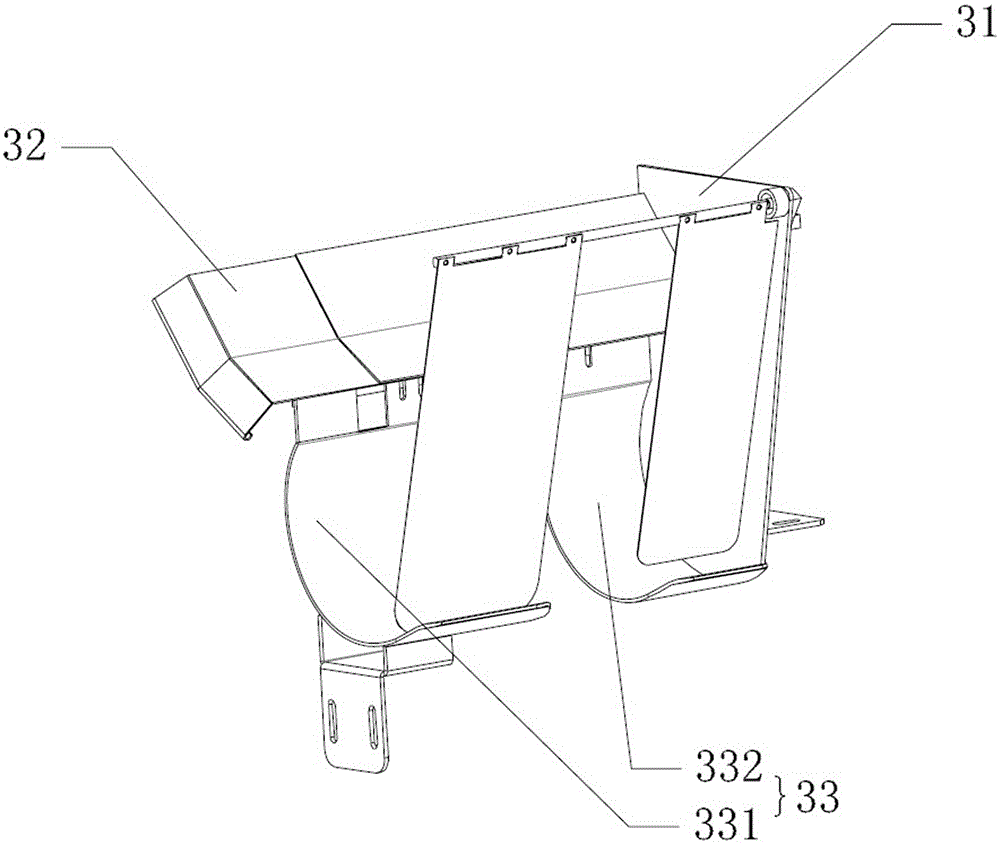

[0027] The automatic strapping device for shoulder straps of the present invention is mainly used for automatic strapping of bras and underwear shoulder straps according to quantity, so as to realize the automation of the strapping process, reduce production costs, and reduce labor intensity. Please refer to figure 1 , The automatic strapping device includes: a fixed frame 1, a material clamping mechanism 2, a material carrying mechanism 3, a pushing and twisting mechanism 4, a cable tie cutting mechanism 5, a cable tie clamping mechanism 6, and a material unloading mechanism 7. Wherein, the fixed frame 1 is used to fix each sub-organization as the support of the whole device to keep each sub-organization relatively fixed; the clamping mechanism 2 is used to clamp the required binding materials and transport them to the material carrying mechanism 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com