Transmission gear of washing machine

A transmission device, washing machine technology, applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of insufficient transmission force and low centrality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

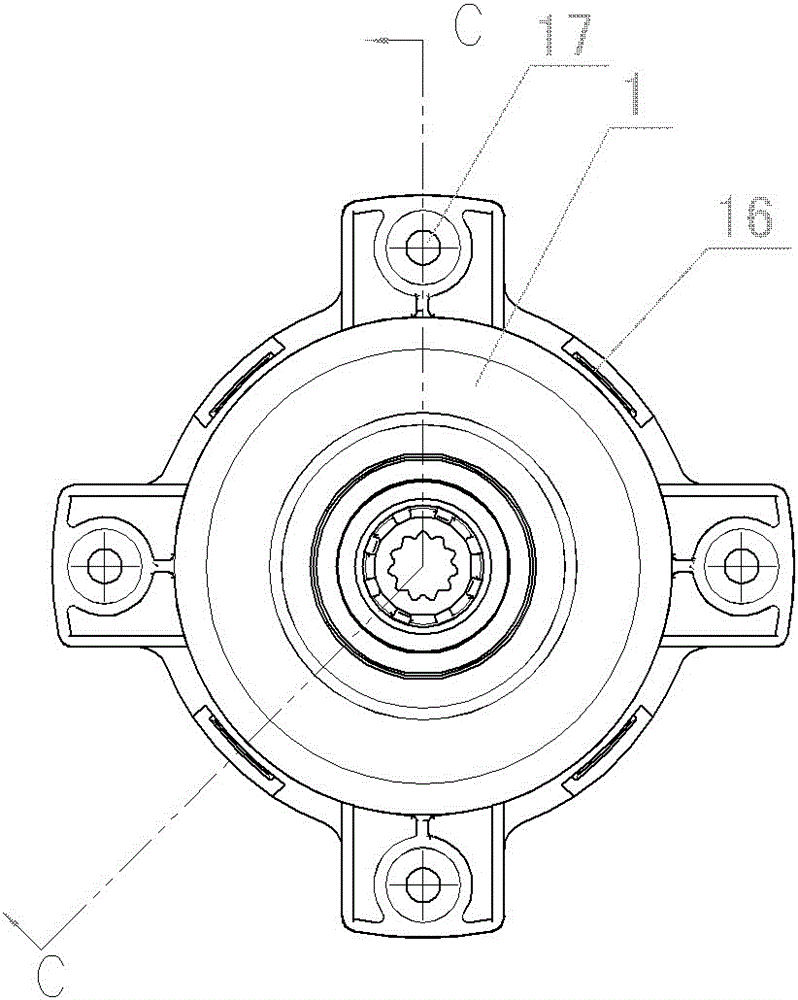

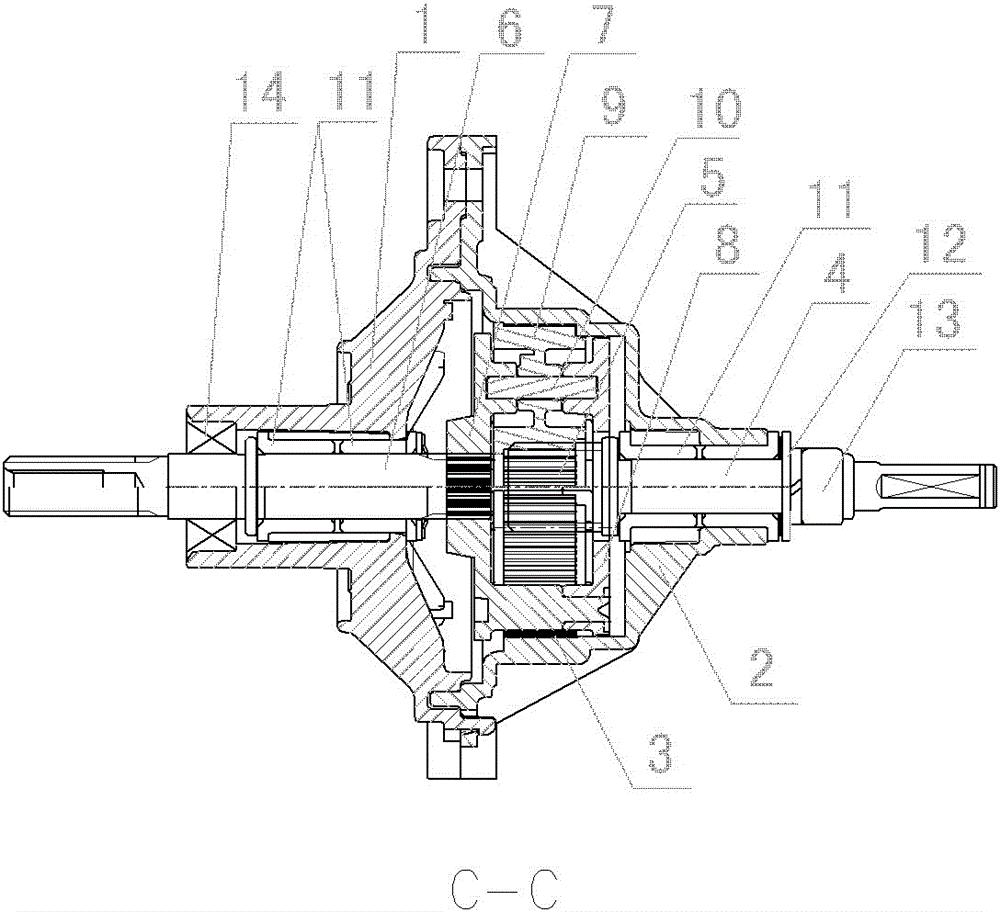

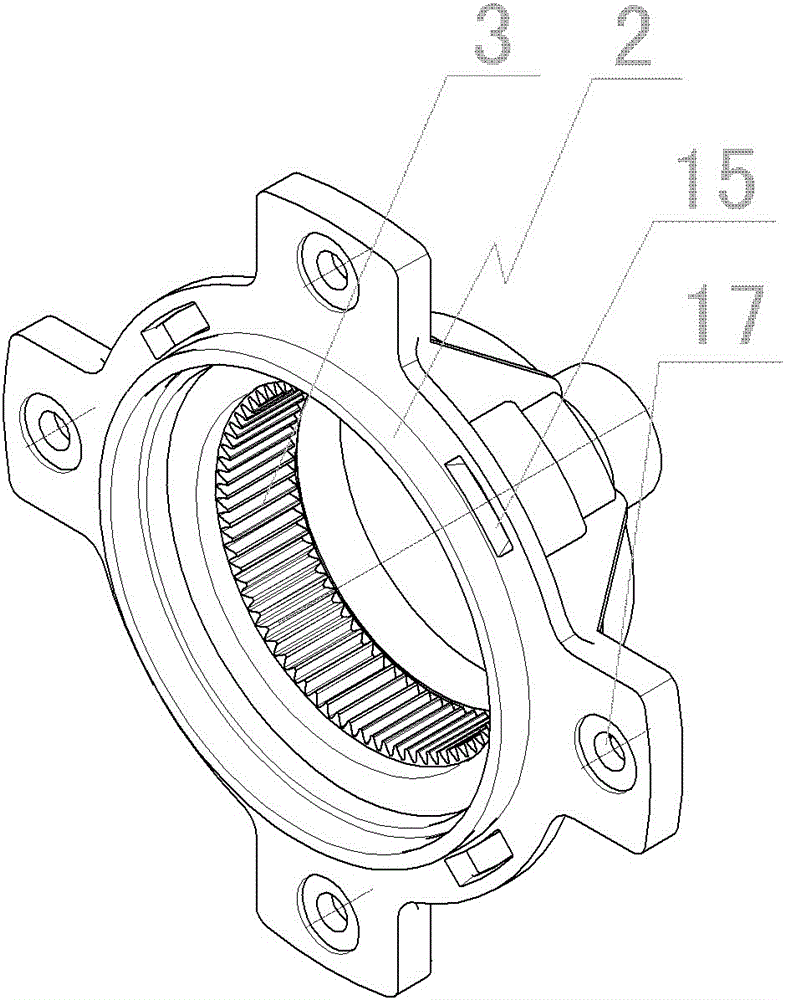

[0014] See figure 1 , figure 2 , image 3 , Figure 4 As shown, a transmission device for a washing machine includes an upper gear case 1 and a lower gear case 2, the upper gear case 1 and the lower gear case 2 are fixedly engaged to form a gear installation cavity, and the inner wall of the lower gear case 2 is provided with internal teeth Ring 3, one end of the input shaft 4 passes through the lower gear housing 2 and extends into the gear installation cavity, the end of the input shaft 4 located in the gear installation cavity is fixedly installed with a central gear 5, and one end of the output shaft 6 extends through the upper gear housing 1 The gear installation cavity, the upper planetary disc 7 is fixedly installed on the end of the output shaft 6 located in the gear installation cavity, the upper planetary disc 8 is movable on the input shaft 4, and the lower planetary disc 8 matched with the upper planetary disc 7 is installed around the center gear 5. The planet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com