Double-runner filtering die head and screen structure suitable for reclaimed material production

A technology of recycled materials and dual flow channels, applied in the direction of climate change adaptation, etc., can solve problems such as extrusion into micropores and blockage, and achieve the effects of stable extrusion, convenient screen change, and controllable flow direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

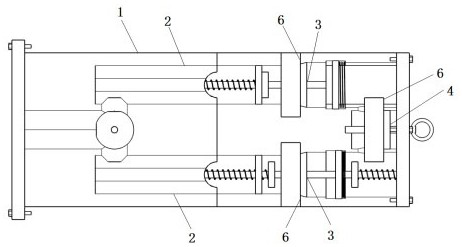

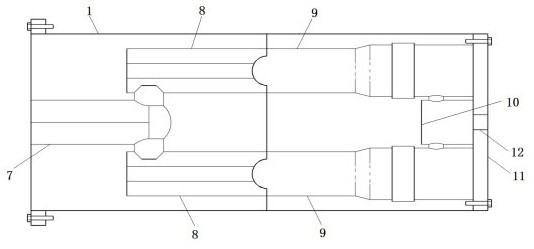

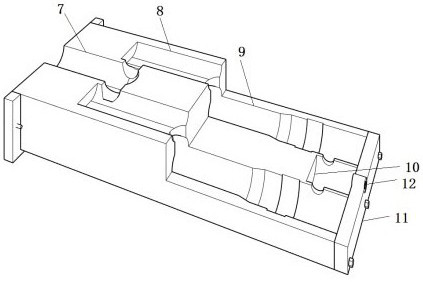

[0057] like figure 1 As shown, a dual-flow filter die and screen structure suitable for the production of recycled materials includes a casing 1, which is characterized in that the feeding end of the casing 1 is connected to the extruder, and the casing 1 is processed with A single-pass flow channel 2 that can split fluids in two ways; a filter assembly 3 is installed on the single-pass flow channel 2, and the end of the single-pass flow channel 2 merges into the extrusion die 4; when the machine is not shut down, the extrusion die 4 and the screen 5 of the filter assembly 3 can be replaced by the screen changing mechanism 6. The use process: after the molten fluid enters the application, it flows through a single channel Under the action of the second fine filtration, the impurity removal effect is improved, and the quality of the extruded drip irrigation belt is ensured. At the same time, the step-by-step filtration can reduce the frequency of screen changing; by setting the...

Embodiment 2

[0067] like Figure 18-19 As shown, the difference from the first embodiment is that, considering the flow direction control of the above-mentioned split flow channel 8, the cross-sectional shape of the split flow channel 8 is a rounded rectangle; the two center positions of the split flow channel 8 are connected by sealed bearings. There is a rotating shaft 40; the side wall of the rotating shaft 40 is welded with mutually meshing propeller blades 41, and the propeller blades 41 are transitionally matched with the inner wall of the shunt flow channel 8; the two ends of the rotating shaft 40 are connected by keys. 1 is provided with a groove 43 for installing the drive gear 42, which drives the drive gear 42 in one of the shunt channels 8, drives the propeller blades 41 on the rotating shaft 40 to transport fluid in one direction, and the other shunt channel 8 is closed, realizing The flow direction of the shunt flow channel 8 is controlled, and this control method can push th...

Embodiment 3

[0069] like Figure 20 As shown, the difference from the first embodiment is that, considering that the above-mentioned fluid is easy to flow back into the filter channel 9 after entering the extrusion die 4, in order to avoid the above phenomenon, the left or right side of the filter channel 9 The round pipe section 16 is fixed with a non-return plate 44. The non-return plate 44 can be arranged on one side alone or on both sides at the same time, and the non-return plate 44 completely closes the filter channel 9. The center of the non-return plate 44 is machined with a The fluid hole 45, the shape of the fluid hole 45 is square, and the diameter of the fluid hole 45 is larger than the diameter of the positioning rod 22 to ensure the passage of fluid; 46 is located on the right side of the non-return plate 44; a tension spring 47 is installed on the left side wall of the positioning rod 22, one end of the tension spring 47 is fixed with the blocking plate 46, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com