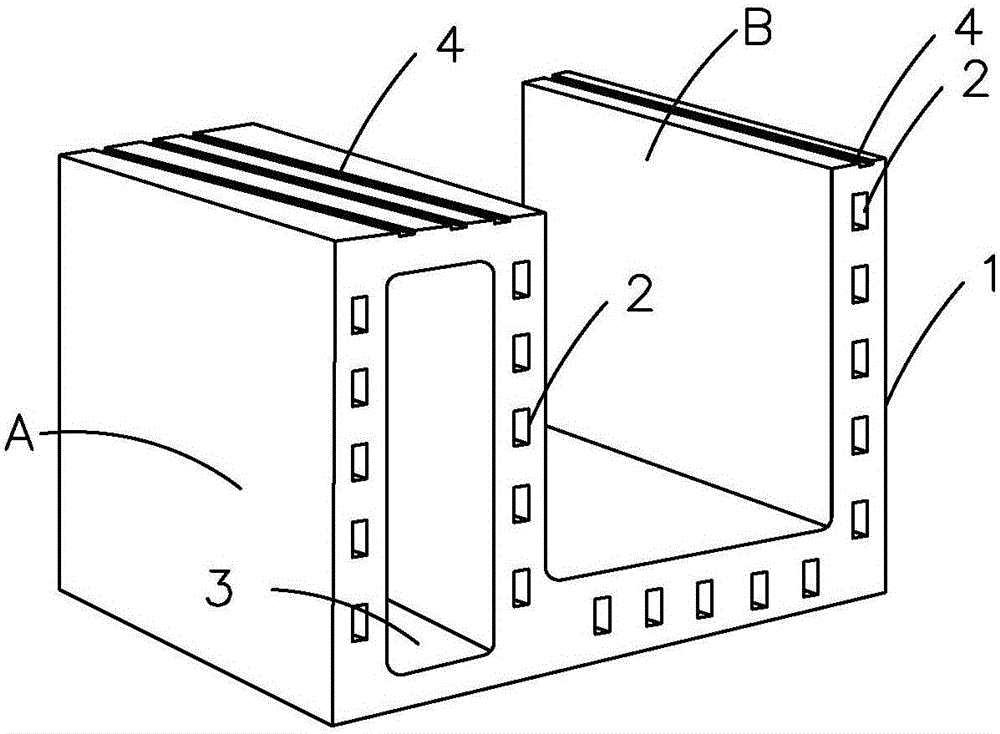

Hollow brick with U-shaped section

A hollow brick and section technology, applied in building materials and other directions, can solve the problems of single hollow brick structure, long firing time, no good seismic performance and shear performance, etc., to ensure seismic performance and shear performance, and reduce building construction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as figure 1 As shown, a hollow brick with a U-shaped section includes a main body 1. The section of the main body 1 is a U-shaped section, and the U-shaped section is divided into two vertical walls, A and B; the thickness of the A wall is the thickness of the B wall Three to four times; the inside of the A wall is provided with a thermal insulation material filling hole 3, in order to simplify the technological process of the hollow brick and improve production efficiency, the thermal insulation material filling hole 3 is square, and the through hole 2 is square or circular. At the same time, the production process is further optimized to reduce the stress concentration inside the main body 1 to ensure the yield rate of the hollow brick production. The four flutes of the insulation material filling holes 3 are all set in arc shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com