Test method for combining strength in combining process of dissimilar materials

A technology of dissimilar materials and bonding process, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of no composite rolling process experiment, no composite interface strength experiment design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Simulation of interfacial bond strength during rolling of carbon steel and stainless steel clad plates:

[0055] Dimensions: The length of the slab is 2000mm, the thicknesses are 10mm (multilayer) and 90mm (base layer), respectively, and the diameter of the roll is 750mm. The width of the edge strip is 200mm, and the gap between the laminated board and the edge strip is 5mm.

[0056] Temperature: slab temperature 1200°C, roll temperature 300°C, ambient temperature 20°C,

[0057] Speed: slab speed 800mm / s, roll line speed 850mm / s,

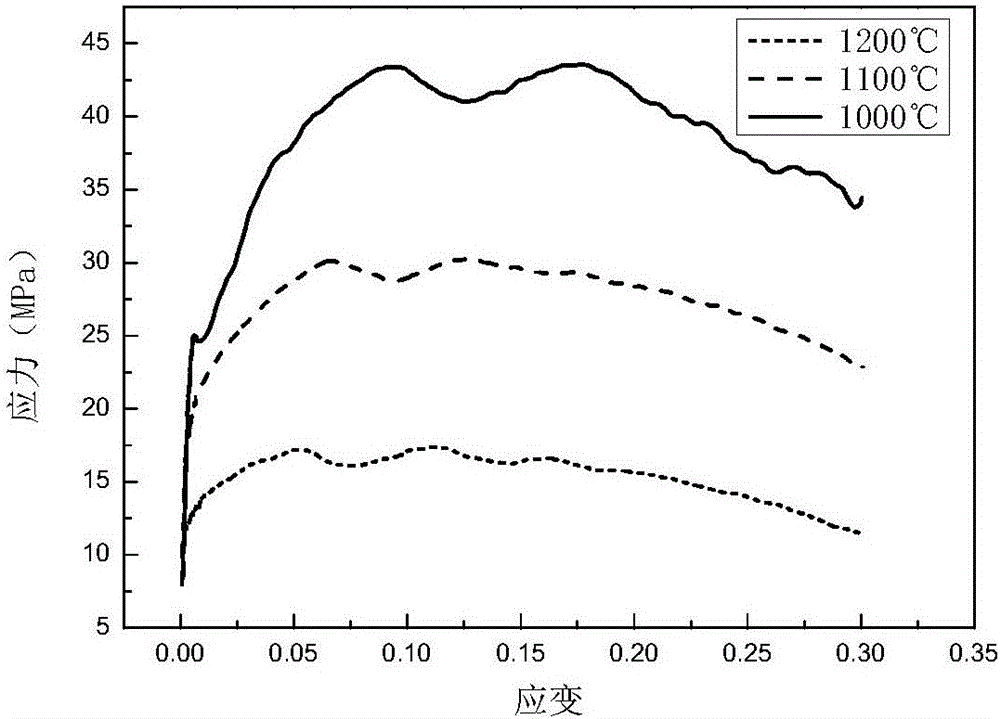

[0058] Material: input stainless steel, carbon steel material parameters, including: density, elastic parameters, plastic parameters, thermal expansion coefficient, thermal conductivity coefficient,

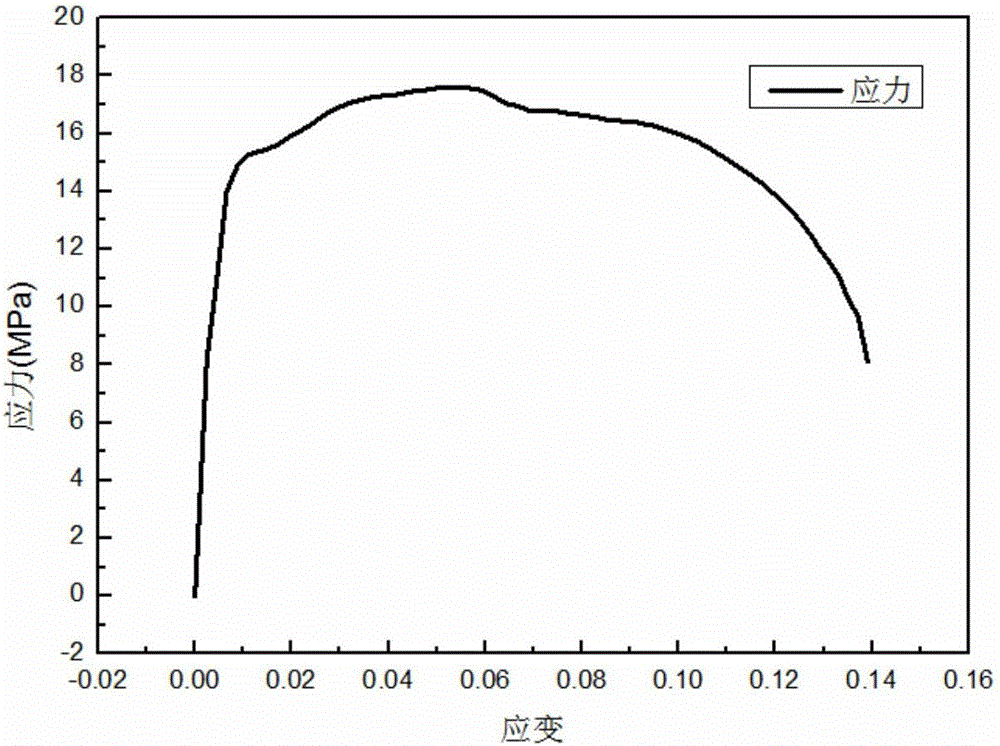

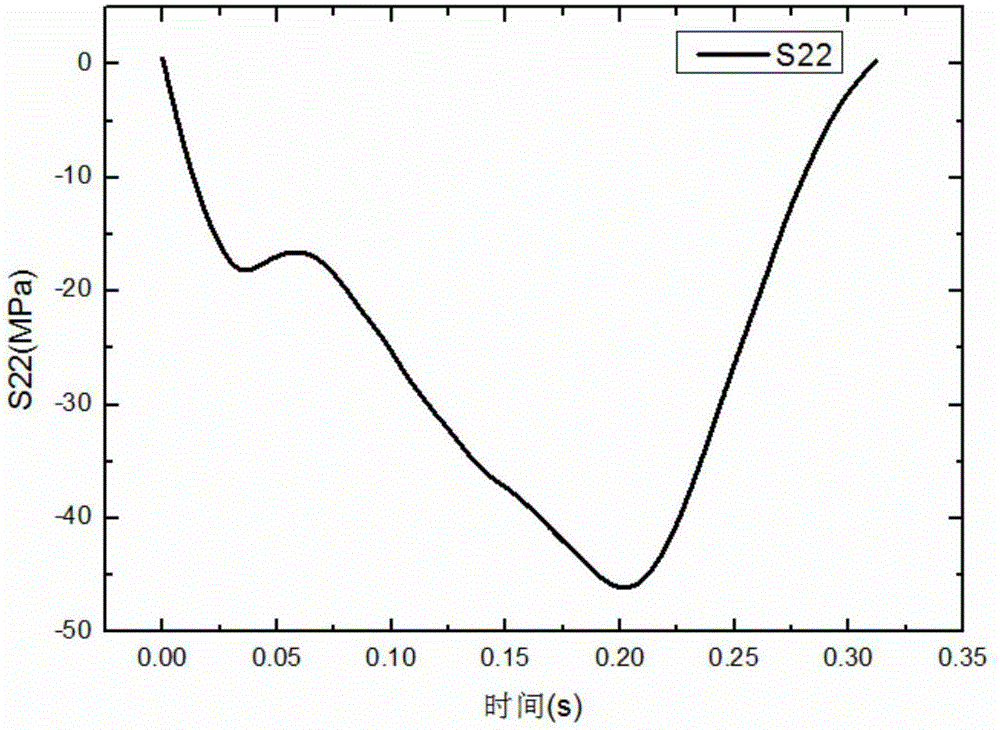

[0059] Set the strain to 10%, the process time to 3s, and perform the simulation. After the simulation, select the stable area of the interface, and select the curves of the interface stress S22 and S12 changing with time, as show...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap