A waste printed circuit board non-metallic powder loaded silica hybrid filler and its preparation method and application

A technology of non-metallic powder and silica, which is applied in the field of waste printed circuit board non-metallic powder-loaded silica hybrid filler and its preparation, can solve the problems of poor interface bonding and deterioration of composite material performance, and achieve improved performance, The effect of hindering the growth and extension of cracks and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

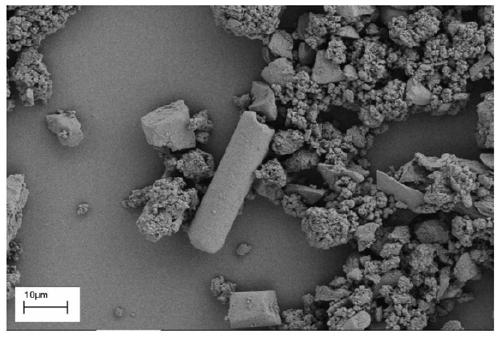

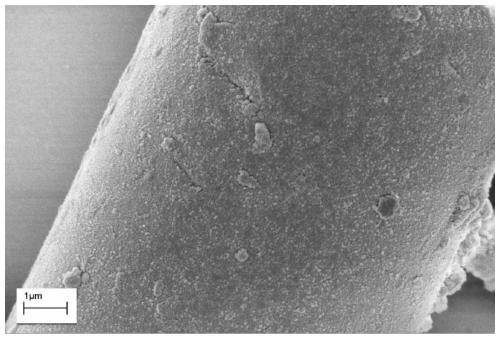

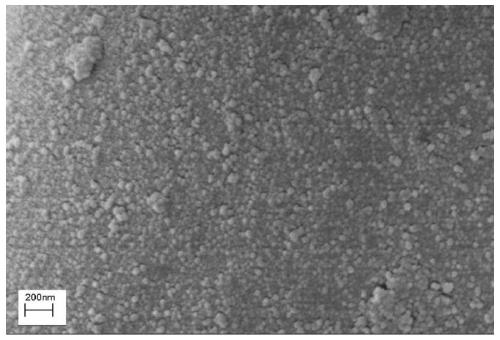

[0032] Disperse 5g of crushed and dried non-metallic powder of waste printed circuit boards into 100ml of absolute ethanol, add 3.0g of 25wt% ammonia water and 8.0g of deionized water, then dropwise add 0.2ml of dibutyltin dilaurate, at 30°C Ultrasonic dispersion for 10 minutes, at 55°C, 2.5g of tetraethyl orthosilicate was added dropwise, stirred and reacted for 2.5 hours, the product was centrifuged and washed with ethanol five times, and dried in a vacuum oven at 100°C for 10 hours to obtain WPCBP-SiO 2 Hybrid filler, that is, waste printed circuit board non-metallic powder loaded silica hybrid filler. Figure 1a , Figure 1b , Figure 1c SEM image of silica hybrid filler loaded on waste printed circuit board non-metallic powder. It can be seen from the figure that a layer of irregular nano-silica particles has grown on the surface of the waste printed circuit board non-metallic powder. Figure 1c It can be further seen that the silica particles are uniformly distributed ...

Embodiment 2

[0034] In a 250 ml three-neck flask, add 10 g of waste printed circuit board non-metallic powder, then add 150 ml of absolute ethanol, 5 ml of deionized water, 10 ml of 25 wt% ammonia water, ultrasonically disperse at 30 ° C for 0.5 hours, and then dropwise add 0.5 ml of dibutyltin dilaurate, and 8g of methyl orthosilicate was added dropwise, reacted at 30°C for 10 hours, centrifuged, washed 8 times with absolute ethanol, and dried in a vacuum oven at 60°C for 24 hours to obtain WPCBP- SiO 2 Hybrid packing. figure 2 is WPCBP-SiO 2 The thermogravimetric curve of the hybrid filler, it can be seen from the figure that the thermal stability of the waste printed circuit board non-metallic powder is significantly enhanced after the silica particles are loaded. image 3 is WPCBP and WPCBP-SiO 2 The infrared spectrum of the hybrid filler, it can be seen from the figure that the Si-O stretching vibration peaks have shifted significantly (from 1032cm -1 to 1092cm -1 ), the change ...

Embodiment 3

[0036] The WPCBP-SiO prepared in 20 g embodiment 1 2Add the hybrid filler to 100g of 191# o-phthalic unsaturated polyester resin, mix well with a three-roll mill, then add 1.0g of cobalt isooctanoate accelerator and 2.0g of methyl ethyl ketone peroxide curing agent at room temperature, and stir for 5 minutes respectively , after vacuum defoaming treatment, pour it into a polytetrafluoroethylene mold for room temperature curing for 4 hours, and then put it in a blast oven at 60°C for post-curing for 10 hours to obtain non-metallic powder of waste printed circuit boards modified by isocyanate-terminated prepolymers / Unsaturated polyester composite. Figure 4a , Figure 4b , Figure 4c , Figure 4d is the SEM image of the impact section added to the unsaturated polyester matrix, from Figure 4a , Figure 4b It can be seen that the WPCBP without silica is basically exposed in the unsaturated polyester, and the interfacial bonding between the polymer matrix and the polymer mat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap