A kind of superfine boron nitride porous fiber toughened WC composite material and preparation method thereof

A porous fiber and composite material technology, applied in the field of alloy materials, can solve the problems of toughened WC composite materials that have not been reported, and achieve high hardness, good oxidation resistance, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

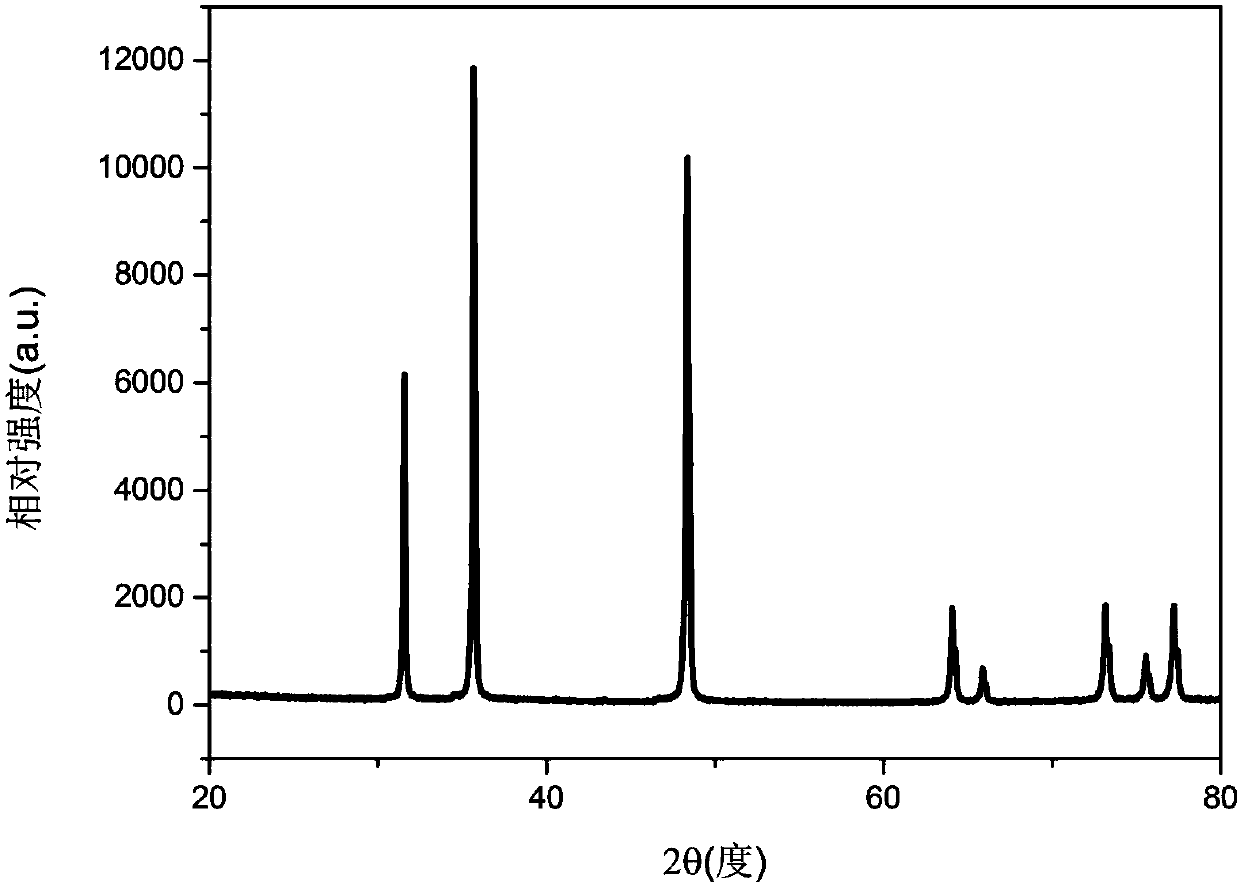

Image

Examples

Embodiment 1

[0028] A kind of superfine boron nitride porous fiber toughened WC composite material of this embodiment is prepared by the following method:

[0029] (1) 99.95g WC (0.2μm, purity >99.9%, Xuzhou Jiexin Material Technology Co., Ltd.), 0.05g ultrafine boron nitride porous fiber (outer diameter 20-60nm, Hebei University of Technology Boron Nitride Material Research Center ), pour in the 250ml cemented carbide jar, then add ethanol as solvent (the volume of gained mixed slurry is no more than 2 / 3 of ball mill jar volume), obtain mixed slurry; The ball mill jar that mixed slurry is housed is placed Carry out wet ball milling (rotating speed 180r / min, ball milling time is 30h) on planetary ball mill, obtain ball mill slurry;

[0030] (2) placing the ball mill slurry in a vacuum drying oven to dry until the residual solvent content is ≤1%, taking out the dried powder, crushing, and sieving to obtain a composite powder with a particle size of ≤300 μm;

[0031] (3) Take 28g of composi...

Embodiment 2

[0035] A kind of superfine boron nitride porous fiber toughened WC composite material of this embodiment is prepared by the following method:

[0036] Steps (1)~(2) are identical with embodiment 1;

[0037] (3) Take 28g of composite powder and put it into the inner diameter and outer diameter In the cylindrical graphite mold, the powder, the die and the punch are separated by graphite paper for demoulding, and the die is also covered with a layer of 10mm thick graphite felt to reduce heat radiation loss; The graphite mold filled with composite powder is placed in a spark plasma sintering furnace for sintering to obtain ultrafine boron nitride porous fiber toughened WC composite material. The sintering parameters are: the sintering current type is DC pulse current, the sintering atmosphere is low vacuum (≤6Pa), the sintering pressure is 30MPa, the heating rate is 100°C / min, and the temperature measurement method is infrared temperature measurement (≥570°C), The sintering t...

Embodiment 3

[0040] A kind of superfine boron nitride porous fiber toughened WC composite material of this embodiment is prepared by the following method:

[0041] Steps (1)~(2) are identical with embodiment 1;

[0042] (3) Take 28g of composite powder and put it into the inner diameter and outer diameter In the cylindrical graphite mold, the powder, the die and the punch are separated by graphite paper for demoulding, and the die is also covered with a layer of 10mm thick graphite felt to reduce heat radiation loss; The graphite mold containing the composite powder was placed in a spark plasma sintering furnace for sintering to obtain ultrafine boron nitride nanofiber toughened WC composites. The sintering parameters are: the sintering current type is DC pulse current, the sintering atmosphere is low vacuum (≤6Pa), the sintering pressure is 50MPa, the heating rate is 300°C / min, and the temperature measurement method is infrared temperature measurement (≥570°C), The sintering temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap