Electromagnetic lock welding device and method assisted by ultrasonic vibration

A technology of ultrasonic vibration and electromagnetic lock, applied in the field of electromagnetic forming connection, can solve the problems of difficult plate forming control, easy to generate cracks, etc., and achieve the effect of avoiding cracking defects, easy control, and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0055] Aiming at the problem that the forming control of the plate is very difficult and cracks are easy to occur in the existing traditional electromagnetic riveting process, the invention provides an ultrasonic vibration-assisted electromagnetic lock welding device and method.

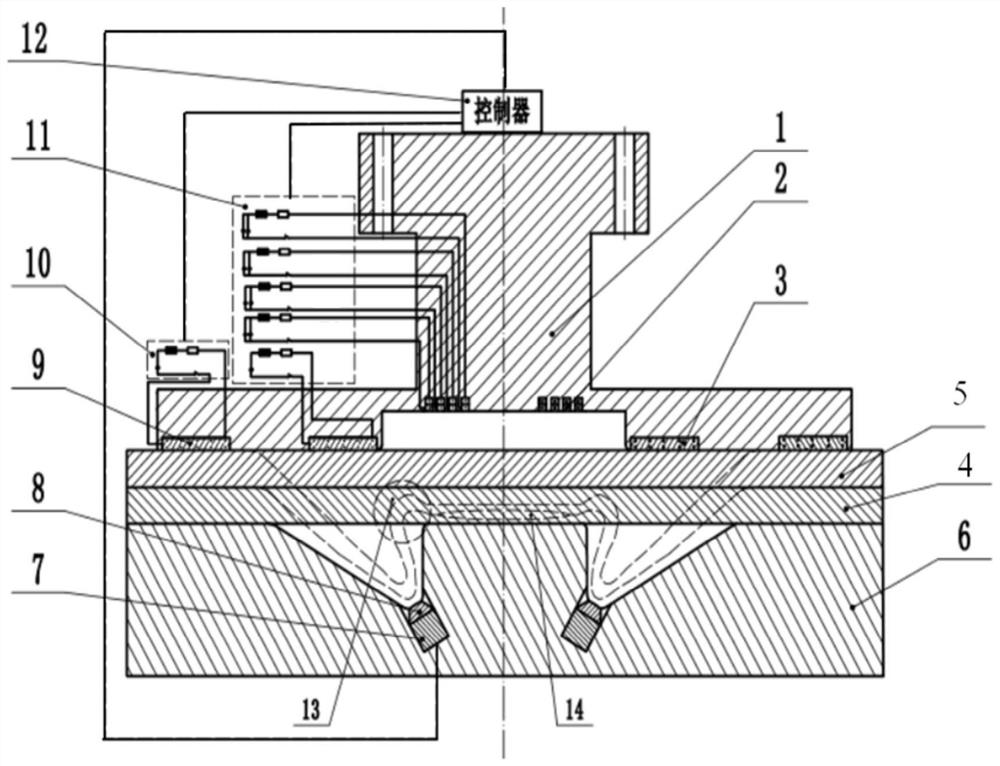

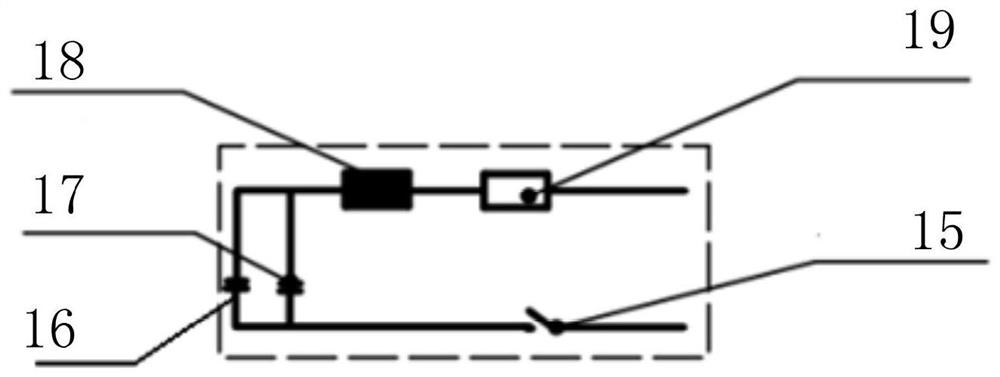

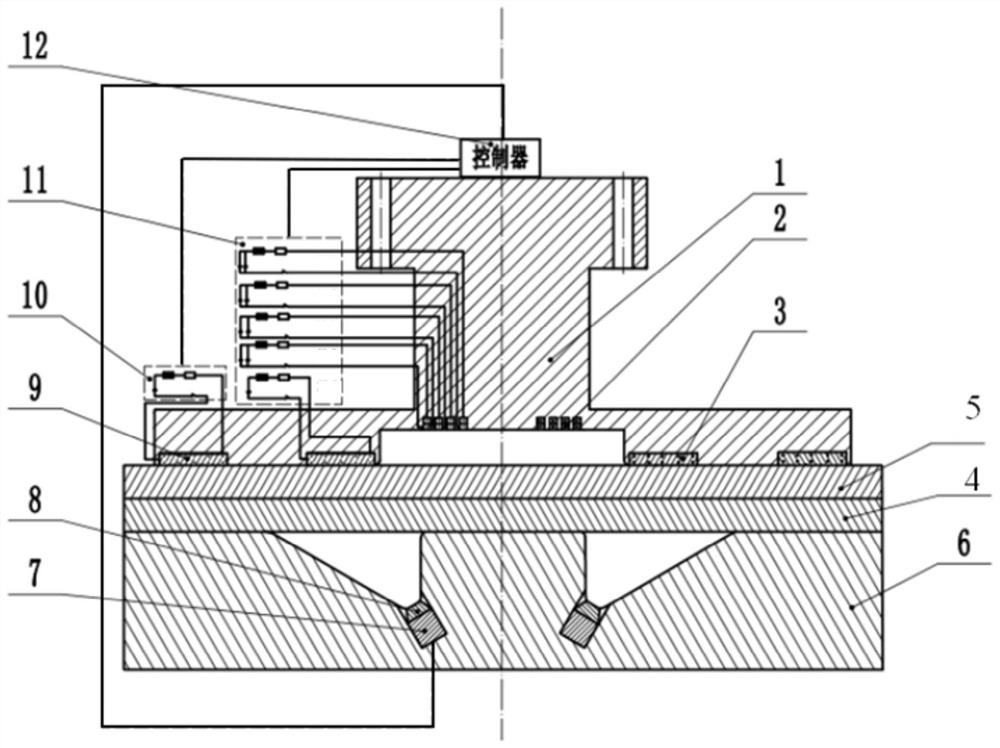

[0056] Such as Figure 1 to Figure 6 As shown, the embodiment of the present invention provides an ultrasonic vibration-assisted electromagnetic locking welding device, including: a lower mold 6, an ultrasonic auxiliary device is arranged in the lower mold 6, and a first The metal plate 4 and the second metal plate 5; the upper mold 1, the upper mold 1 is fixedly arranged above the lower mold 6, and the upper mold 1 and the lower mold 6 are coaxially arranged; the controller 12...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap