A miniaturized dielectric phase shifter

A phase shifter and dielectric technology, which is applied in waveguide devices, electrical components, circuits, etc., can solve the problems of unstable performance, small phase shift amount, and high cost of dielectric boards, and achieve the reduction of nonlinear electrical connection points and large output Phase delay, easy to process and manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

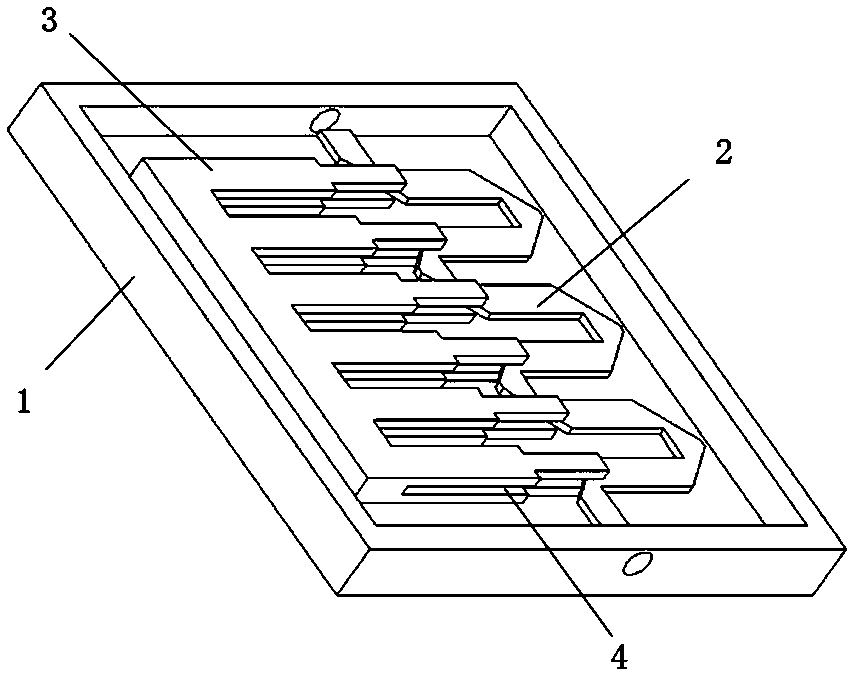

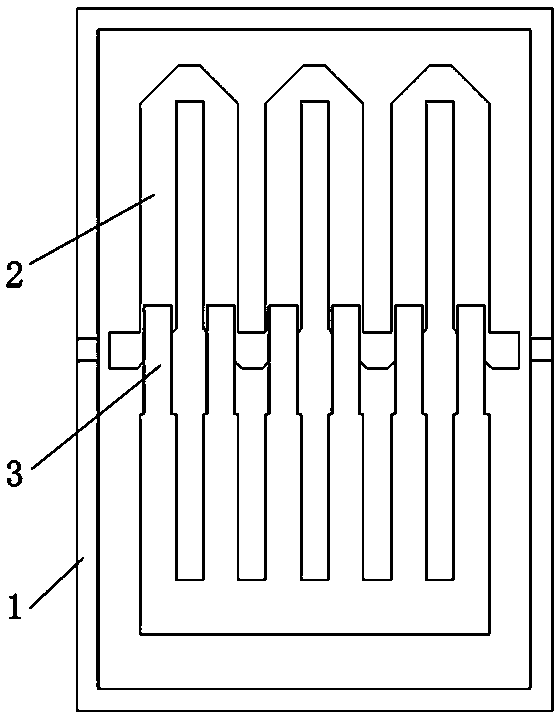

[0038] see figure 2 , further speaking, a transmission line 2 and a dielectric block 3 are arranged in the box body 1 . The longitudinal section of the dielectric block 3 that contains a side groove 4 is U-shaped, such as Figure 4 shown.

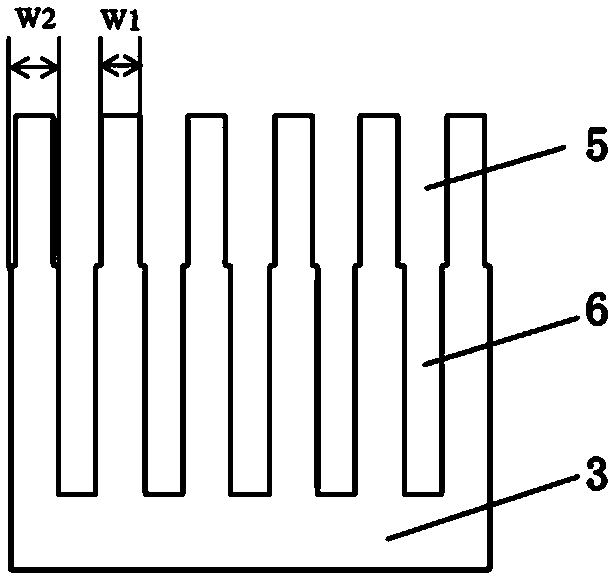

[0039] see image 3 , more than one first-level opening 5 is provided on the top edge of the dielectric block 3 on the side close to the transmission line 2 . A second-stage opening 6 is provided on the dielectric block 3 on one side of the closed end of each first-stage opening 5 . That is, the edge of the top surface of the dielectric block 3 is a stepped protrusion, and the stepped protrusion extends toward the direction of the transmission line 2 .

[0040] The width of the first stage opening 5 is greater than the width of the second stage opening 6 .

[0041] When the dielectric block 3 with the first-level opening 5 and the second-level opening 6 is displaced relative to the transmission line 2, the dielectric area covered on t...

Embodiment 2

[0047] see Figure 6 , further speaking, a transmission line 2 and a dielectric block 3 are arranged in the box body 1 . The longitudinal section of the dielectric block 3 with one side groove 4 is U-shaped.

[0048] More than one set of through-hole groups 7 is provided on the top edge of the dielectric block 3 on the side close to the transmission line 2 .

[0049] The through hole group 7 includes two or more circular holes. The radius of the circular holes in each group of through hole groups 7 gradually increases from the inside to the outside. The distance between two adjacent groups of through hole groups 7 is between 1 mm and 3 mm.

[0050] In this structure, by changing the size of the circular hole, the area of the dielectric block 3 covering the transmission line 2 is changed, thereby changing the equivalent energy-saving constant of the corresponding position, and then changing the characteristic impedance of the transmission line, finally realizing impedance ...

Embodiment 3

[0056] see Figure 7 , further speaking, two transmission lines 2 and a dielectric block 3 are arranged in the box body 1 . The longitudinal section of the dielectric block 3 containing two side grooves 4 is H-shaped, such as Figure 9 shown.

[0057] see Figure 8 The top edges of the two ends of the dielectric block 3 close to the transmission line 2 are respectively provided with more than one first-level opening 5 . A second-stage opening 6 is provided on the dielectric block 3 on one side of the closed end of each first-stage opening 5 . That is, the top surface of the dielectric block 3 is approximately in the shape of a "thirty".

[0058] Moving the position of the dielectric block 3 relative to the transmission line 2, the covered area of the upper transmission line 2 becomes larger, and the equivalent power-saving constant becomes larger, and the phase change of the output port of the upper transmission line 2 is -Δ. At the same time, The covered area of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com