Underwater sealed cabin cable connecting penetrator

A technology of penetrating parts and sealed cabins, which is applied in the field of cable connection parts between sealed cabins and propellers, can solve the problems of complicated plugging process, poor sealing performance, inconvenient replacement, etc., and achieves wide application range, good conductivity, and production convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

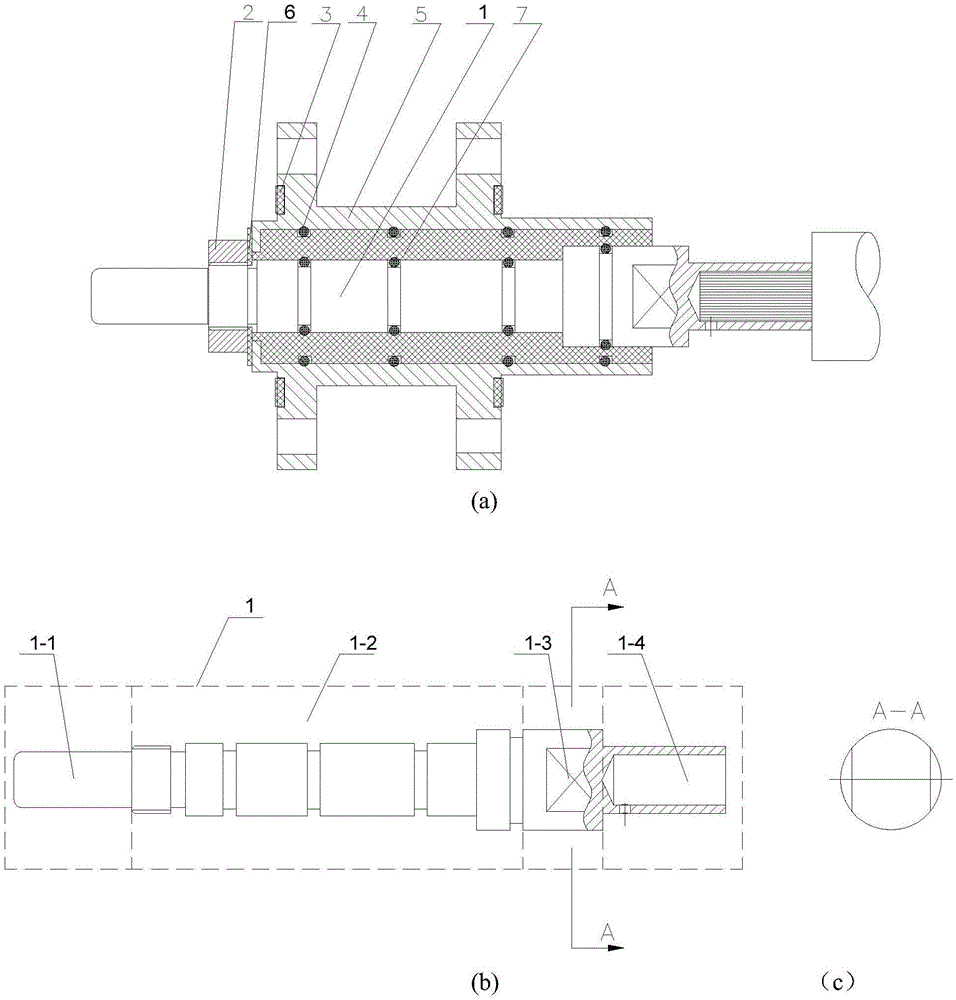

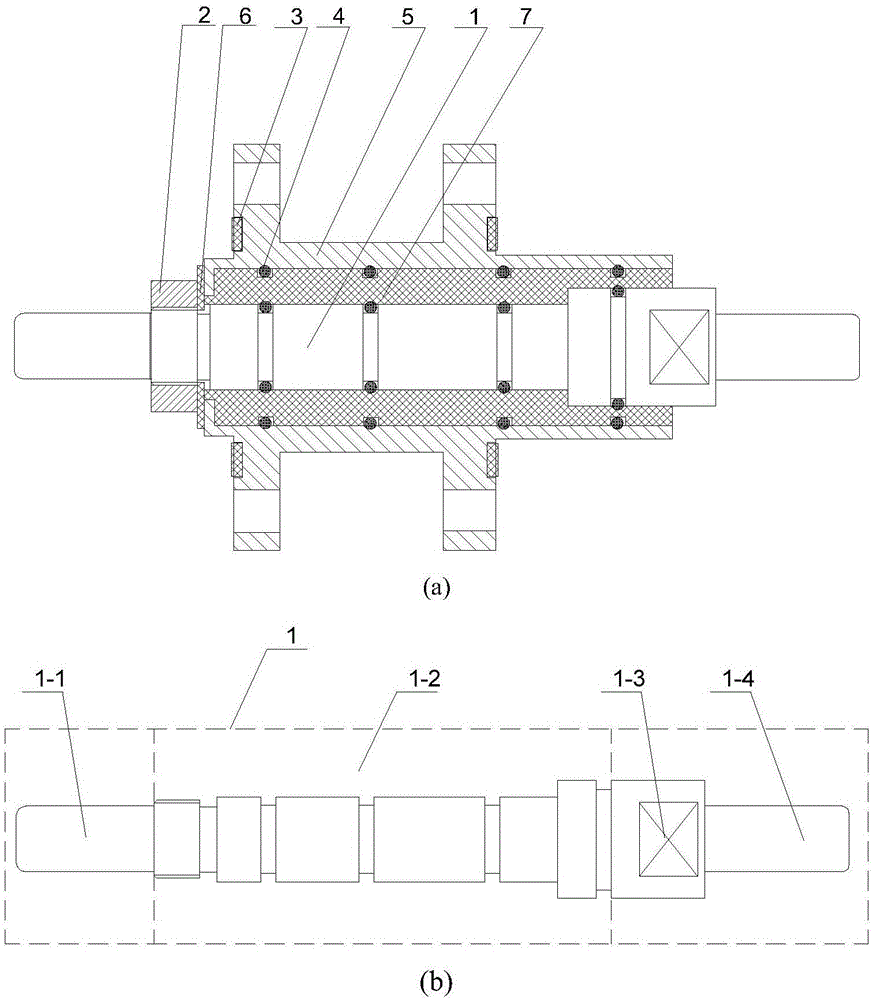

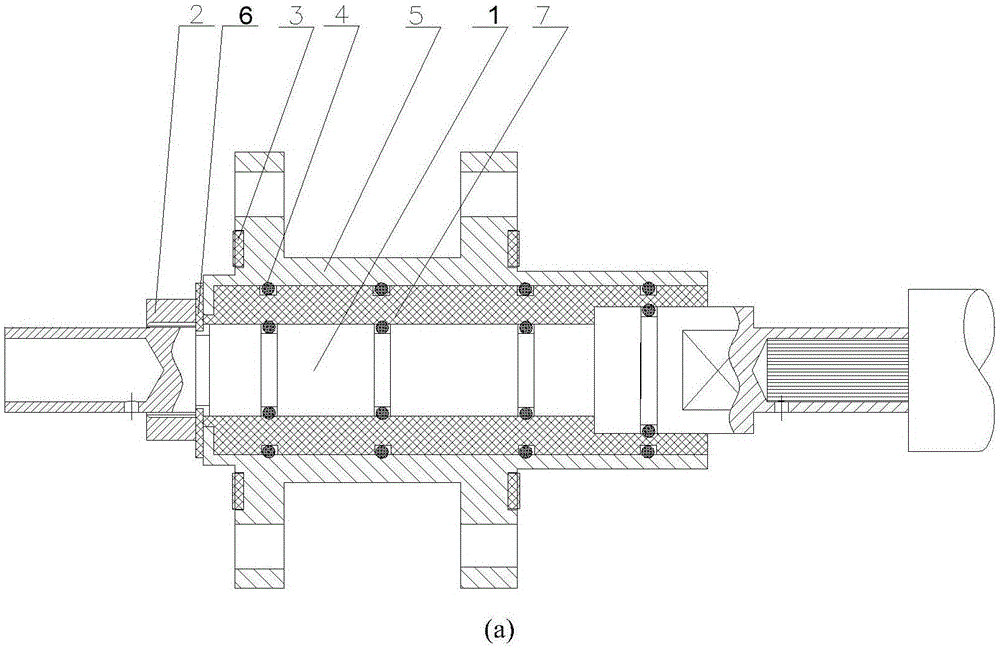

[0021] Specific implementation mode one: the following combination Figure 1 to Figure 3 This embodiment is described. The cable connection penetration of the underwater airtight cabin in this embodiment includes a pin 1, a mounting nut 2, a penetration housing 5, an insulating gasket 6 and an insulator 7;

[0022] The pin 1 of one-piece structure is divided into four sections, from front to back are the front-end electrical connection structure section 1-1, the pin main body section 1-2, the flat head structure section 1-3 and the rear-end electrical connection structure section 1- 4;

[0023] The pin 1 is inserted into the inner cavity of the penetration housing 5, and the main body section 1-2 of the pin remains in the inner cavity of the penetration housing 5, between the main body section 1-2 and the inner wall of the penetration housing 5 filling insulator 7;

[0024] The mounting nut 2 used to fix the pin 1 is arranged at the head end of the penetrating piece casing 5...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment further explains Embodiment 1, and also includes an elastic washer 3. Both ends of the penetrating piece casing 5 are flange structures. The axis is vertical, the circular holes on the flanges are threaded holes, elastic washers 3 are arranged on the outer end surfaces of the two sets of flanges, and the elastic washers 3 are located inside the threaded holes.

[0032] One side thereof is directly connected with the airtight cabin by using fixing bolts, washers and nuts as required, and elastic washers 3 are respectively arranged on the inner side of the thread for waterproofing.

specific Embodiment approach 3

[0033] Specific Embodiment Three: This embodiment further describes Embodiment One or Two, and also includes O-rings 4, a plurality of O-rings 4 are evenly distributed on the outer surface of the main body section 1-2 of the pin, and on the outer surface of the insulator 7 The same axial position corresponds to the same number of O-rings 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com