Mega drop entertainment machine driven by linear motor

A linear motor and amusement machine technology, applied in the field of jumping amusement machines, can solve the problems of large maintenance, complex structure and low energy efficiency of the equipment's pneumatic and hydraulic pipelines, and achieve efficient park maintenance, simple structure and no mechanical loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

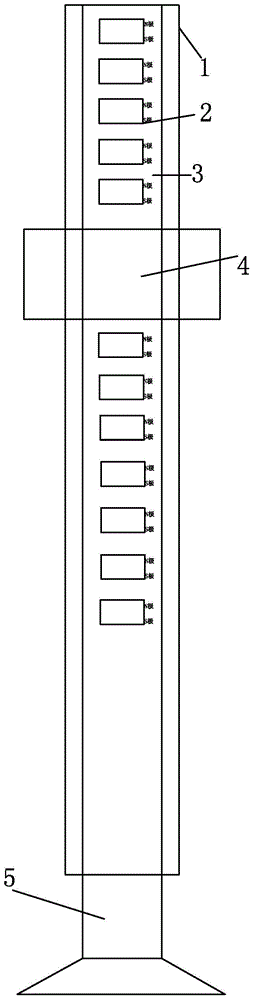

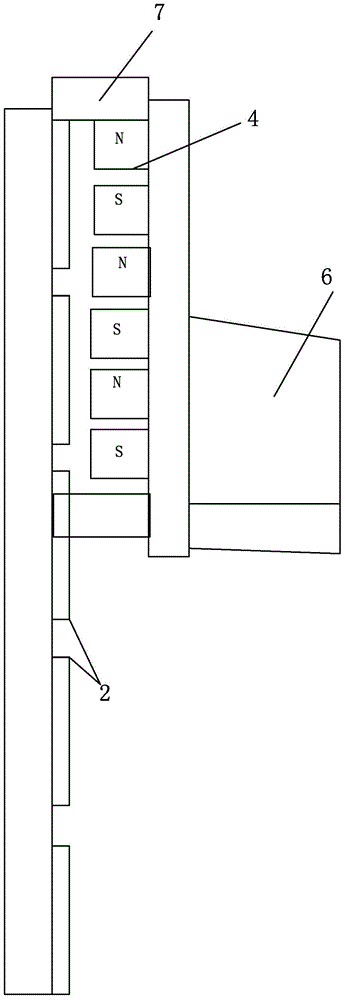

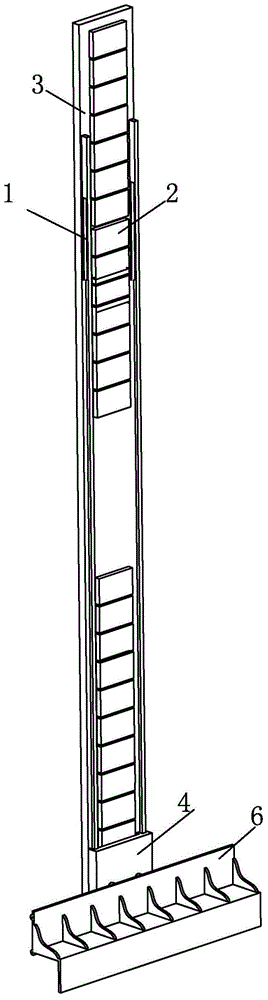

[0015] In order to further illustrate the principle and structure of the present invention, different embodiments of the present invention will be described respectively with reference to the accompanying drawings.

[0016] like figure 1 , figure 2 and image 3 As shown, the jumping amusement machine driven by a linear motor in the present invention includes a seat 6 and an ejection tower 5, wherein the guide rail 1 for the seat 6 to move up and down is installed in the ejection tower 5, that is, the seat 6 passes through the guide rail frame and the ejection tower 5. The guide rail 1 on the tower 5 is connected, and an automatic lubricant adding device is provided between the guide rail frame and the guide rail 1, so that the seat 6 can move up and down along the guide rail 1. Seat 6 can be single-row structure, also can be multi-row structure, and seat 6 also can be replaced by cockpit in addition, as image 3 As shown, the entire row of seats 6 can move vertically up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com