Automatic turning material frame device for cleaning valve lifters

A valve lifter and automatic flipping technology, which is applied to cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problem of workpiece position restrictions, workpieces that cannot meet cleaning requirements, workpieces that are blown away or blown away. Flying and other problems, to achieve a good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is specifically described below by examples, it is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention, those skilled in the art can understand the present invention according to the contents of the present invention Invention to make some non-essential improvements and adjustments.

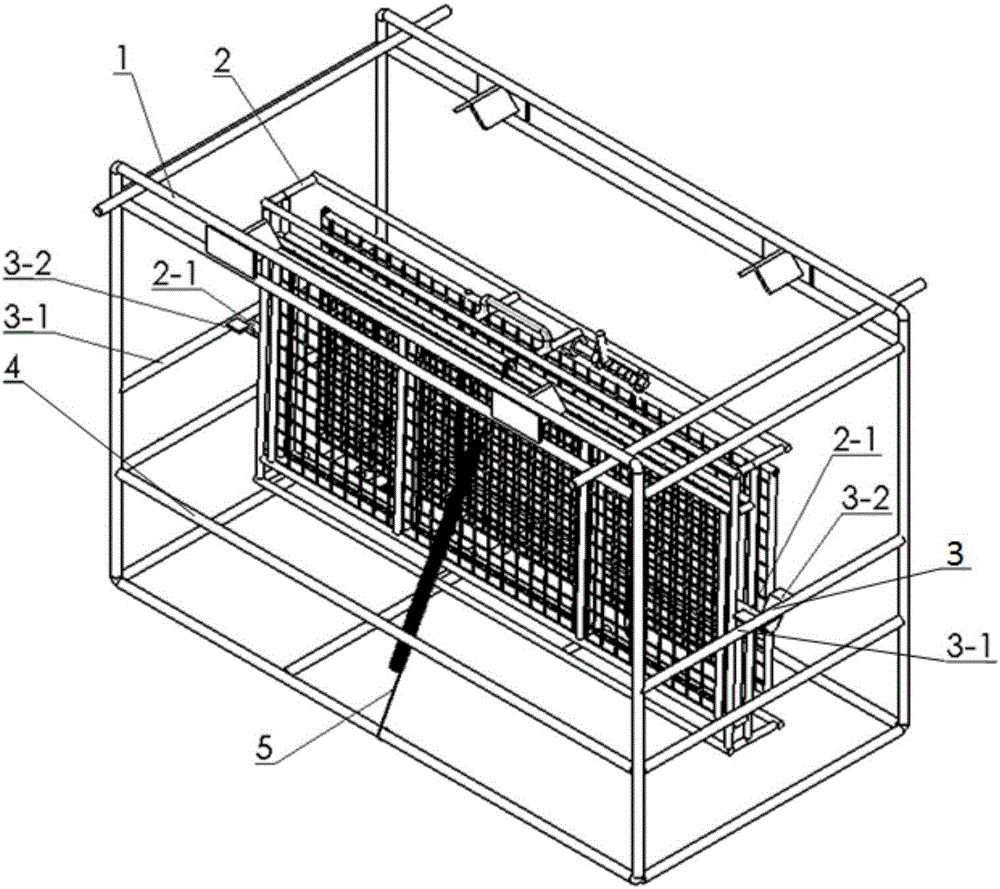

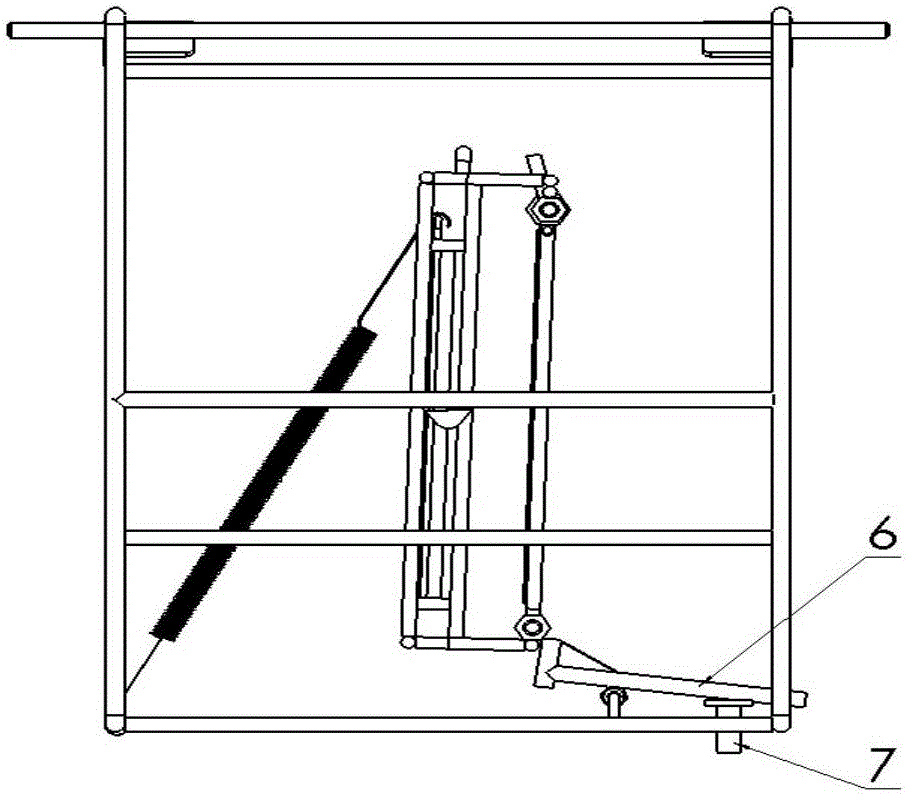

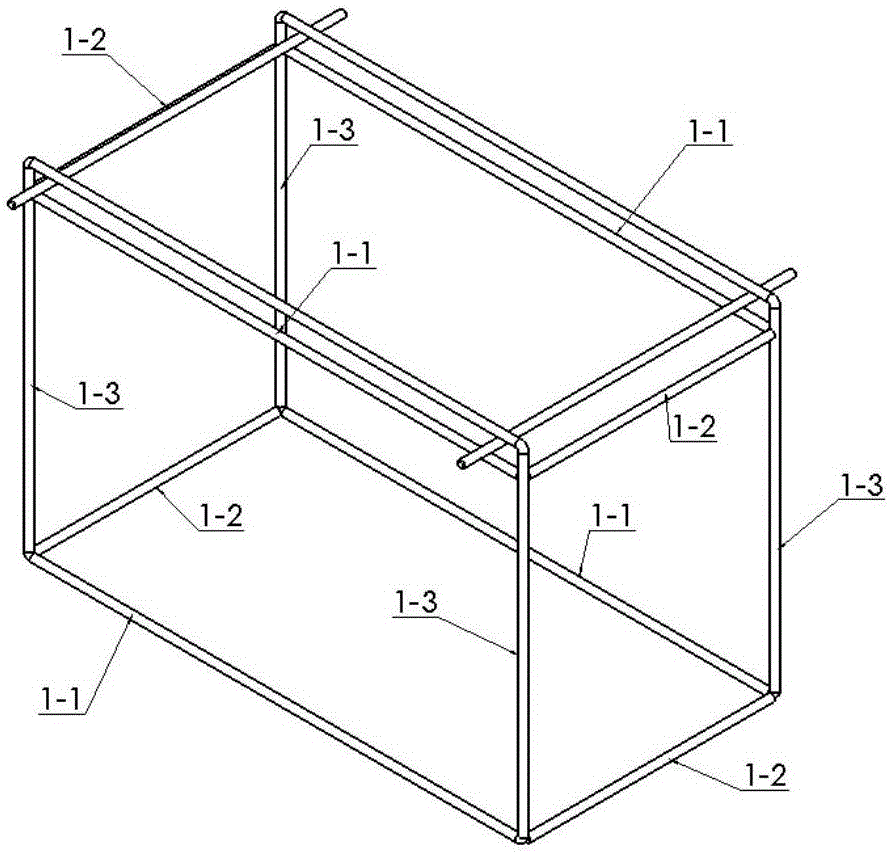

[0012] Such as figure 1 and figure 2 The shown automatic flip material frame device for ultrasonically cleaning valve lifters includes a material frame 1, a material frame 2, a support device 3, a horizontal frame 4, a spring 5, a ejector rod device 6 and a thimble 7, and the material frame 1 is A cuboid frame welded by the first round steel 1-1, the second round steel 1-2 and the third round steel 1-3 three groups of round steel, the support device 3 is composed of a bearing rod 3-1 and a support plate 3-2, the load-bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com