Cylindrical grinding double top clamping tool

A double-top and cylindrical grinding technology, which is applied in the direction of grinding workpiece supports, grinding drive devices, manufacturing tools, etc., can solve the problem of shaking during the sliding process of the carriage, increased shaking of the top, and increased coaxiality of the product, etc. problem, to achieve the effect of reducing the shaking gap, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

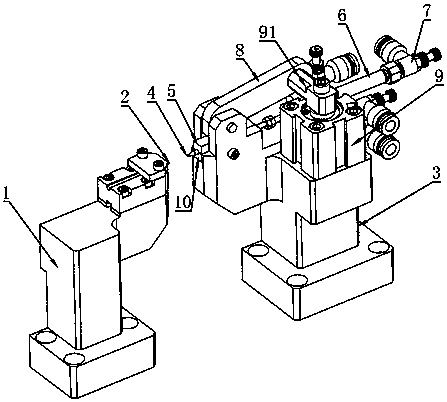

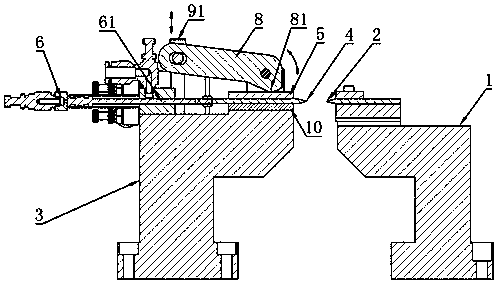

[0017] Such as figure 1 The cylindrical grinding double-top clamping tool shown includes left base 1, left top 2, right base 3, right top 4, pressing block 5, jacking cylinder 6, air pressure regulating valve 7, rocker arm 8, pressing Cylinder 9, guide block 10.

[0018] The position of the left base 1 is fixed, and the left top 2 is fixed on the left base 1. The position of the right base 3 is fixed, and the right top 4 is installed on the left base 3, and the tops of the two tops on the left and right are relative and coaxial.

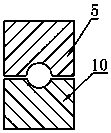

[0019] The device mode of right top 4 is as follows figure 1 , figure 2 As shown: the guide block 10 is fixed on the right base 3, the guide block 10 is provided with a guide groove, the guide groove is in the same direction as the left top, the right top 4 is located in the guide groove, the compression block 5 is fastened above the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com